Kilmer Innovations in Packaging Takes on the Challenge of Sustainability in Sterile Packaging

The grassroots effort is looking for sustainability game changers, explained Kilmer Innovations in Packaging speakers at MD&M West 2021. Learn more at MD&M Minneapolis.

September 16, 2021

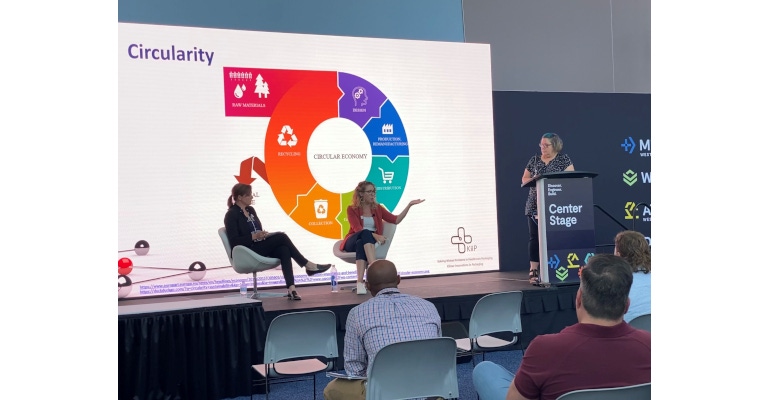

“This is the most exciting time to be in packaging,” proclaimed Jennifer Benolken, MDM & regulatory specialist with DuPont Tyvek Medical Packaging. She shared the quote from Bruce Holmgren, former editorial director of Package Engineering, as she opened the MD&M West 2021 Center Stage panel discussion, "Kilmer Innovations in Packaging (KiiP): Sustainability for Medical Packaging."

Sustainability hasn’t always been a critical priority for the medical device and packaging industries, Benolken acknowledges, but “that is far from true today and what makes it an exciting time,” she said. In fact, that is exactly what a team of medical device packaging professionals is working on right now through the KiiP Sustainability and End-of-Life Solutions industry group.

“Breaking barriers and siloes in the sterile medical device value chain—from package engineers and sterility assurance professionals through to the end users—is a fundamental goal of KiiP,” Benolken said of the grassroots effort. “KiiP is allowing us to break down barriers and have productive conversations about sustainability and other Wicked Problems we have grappled with for years.”

“Sustainability is, by definition, a huge undertaking,” said Jenn Goff, global director of product strategy for Oliver Healthcare Packaging, who joined Benolken for the panel discussion along with Kiley Djupstrom, commercial development leader, Plastic Ingenuity. “For example, sustainability could involve reducing waste from a process by using fewer resources, being more efficient, or removing or reducing energy. By participating in groups like this, we’re looking to share knowledge so other (individual) companies “aren’t constantly reinventing the wheel,” Goff added. “We have a huge opportunity here to broaden our horizons and really make an impact with respect to sustainability.”

Benolken and Djupstrom will be speaking at the upcoming MD&M Minneapolis conference in "Sustainability in Medical Device Packaging" on Thursday, November 4 at 11:00 AM - 11:45 AM. They will be joined by Tanya Magana, principal packaging engineer for Ecolab; Sarah Rosenblum, senior director of sales & marketing at Packaging Compliance Labs; and Sopheak Srun, principal sterilization specialist at Quality Tech Services, Cretex Medical Company.

Collaboration is needed to identify sustainability challenges and opportunities for sterile packaging. “Without collaboration along the value chain, you can’t successfully achieve circularity,” explained Djupstrom, indicating that no one company can tackle the issue alone—it’s got to be a team effort by all involved. “Progress will not be made in a vacuum,” she said. “We are looking at what we can do to advance sustainability upstream.” She adds that it could be helpful to “tap into progress being made in other markets like consumer packaged goods as well as to draw from work being done by the Healthcare Plastics Recycling Council and the Association of Plastics Recyclers.”

Benolken explained that sustainability has been part of KiiP’s focus from the beginning. “Sustainability was a loud and clear priority to address, expressed by many interested in making KiiP happen,” she said.

And Goff said that some of the newest packaging engineers she meets while guest lecturing at MSU are asking about sustainability for sterile medical packaging. “I’m excited to bring these new professionals, who can offer a fresh perspective, into the industry. They will be the next ‘change makers.’ ”

Change will require some effort, though. Some of the biggest challenges medical packaging engineers face when considering sustainability involve “the competing priorities and the disconnects along the value chain that can make progress confusing,” Djupstrom told MD+DI. “There are also different barriers depending on where products are sold, and they often don’t correlate to sustainability goals.”

Goff agreed, listing some of the priorities that packaging engineers must balance as “sustainability, regulatory compliance, and cost.” And, of course, “the patient is always the most critical priority, which is what Kilmer is all about through its focus on sterility assurance,” added Djupstrom. “So how do you balance all of that?”

To answer that question and more, KiiP participants are examining the potential of several sustainability ideas, such as adopting allocated recycled content for medical packaging materials to complement advanced recycling. For instance, “if we can set a framework and help people understand the process of advanced recycling and how it can enable circularity, then medical device companies can correlate this to their sustainability goals. R&D engineers at medical device companies can also look at their own components and find opportunities for advanced recycling of their components as well,” said Goff. Advanced recycling involves breaking down mixed plastic waste to the molecular level so it can be reprocessed into new materials, she explained.

“Sustainability doesn’t just mean recycling,” added Djupstrom. “It’s not just waste—it brings value,” Goff chimed in. “KiiP is planning to take how industry looks at sustainability to a new level.”

“We want to come up with game changers through KiiP,” said Benolken. Once viable sustainability solutions for sterile packaging are identified, she envisions KiiP contributing “to peer-reviewed papers that may lead to change in how we have always done things.”

Goff also sees the potential for KiiP and the sustainability team to act as an incubator. “New designs and processes could come out of our work,” she explained.

Before any of these steps can get underway, Benolken, Djupstrom, and Goff all agreed that bringing together stakeholders from medical device companies as well as along the healthcare supply chain will lead to clarity on the scope, needs, requirements, and challenges of any sustainability approach. “Some of the questions that come up in our discussions have led to the most fruitful discoveries,” said Benolken. “We often ‘think’ we know what others in the value chain do, want, and need (and know), but we are realizing that we have tons to learn from each other, which could lead to solutions to our big, Wicked Problems—a term coined by MSU Professor Laura Bix at a previous HealthPack.

“We need the right people in the right room at the right time with the right passion, because that is where we are going to get something done,” Benolken added. “KiiP is where it can happen.”

Benolken, Djupstrom, and Goff encourage interested stakeholders to join the KiiP LinkedIn group.

Be sure to attend "Sustainability in Medical Device Packaging" at MD&M Minneapolis on Thursday, November 4 at 11:00 AM - 11:45 AM.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)