Susceptibility Testing Requirements for Medical Systems

February 1, 1999

Medical Device & Diagnostic Industry Magazine

MDDI Article Index

An MD&DI February 1999 Column

EMI FIELD NOTES

EMI FIELD NOTES

Tests required in several basic and collateral standards are important to achieving marketability in Europe. Tougher standards are coming soon.

To be marketable in Europe, medical electronic equipment or systems must comply with the Medical Devices Directive (MDD) regarding electromagnetic compatibility (EMC) requirements. The product standard for medical devices, EN 60601-1-2, has been harmonized with the MDD. EN 60601-1-2 is identical to IEC 60601-1-2 and is the collateral standard to IEC 60601-1, which is the general safety standard for medical electrical equipment. IEC 60601-1-2, "Medical Electrical Equipment; Part 1: General Requirements for Safety; 2: Collateral Standard; Electromagnetic Compatibility—Requirements and Tests," was published in April 1993. EN 60601-1-2 was published in November 1993, and it was harmonized with the EMC Directive in August 1995 and with the MDD in September 1995. This article discusses the susceptibility tests required to comply with these standards. It also discusses modifications expected for the upcoming revision of IEC 60601-1-2.

PERFORMANCE CRITERIA

A significant difference between the European EMC standards and the medical device standards (such as EN 60601-1-2) is the performance criteria. For example, the immunity criteria for the collateral standard are based on safety. In contrast, all other EMC standards require evaluation of performance as defined by the manufacturer.

According to EN 60601-1-2:1993, the immunity criteria for medical products are defined as: "equipment and/or system continues to perform its intended function as specified by the manufacturer or fails without creating a safety hazard." Safety hazard is defined by IEC 60601-1 as a "potentially detrimental effect on the patient, other persons, animals, or the surroundings arising directly from equipment." This definition places a great deal of responsibility on the manufacturer and testing laboratory. For example, it is possible for a device to fail safely and still create a safety hazard by its unavailability, such as a diagnostic system that either fails to start or can be interrupted. The standard does not require manufacturers to inform users of such hazards. Although an accredited test laboratory is likely to identify such a malfunction in its test report, the manufacturer is not required to state it in the user manual. Other examples also illustrate a gap in EN 60601-1-2:1993 for defining pass/fail criteria (i.e., safety hazard). This problem has forced Working Group 13 of IEC Technical Committee 62 to define performance criteria more clearly.

EN 60601-1-2 is a generic standard designed to address many different devices. Some medical products, such as systems that measure human physiological signals, require specific immunity levels. Based on the low levels of these signals, it was necessary for the standard to allow for lower immunity levels, provided that the manufacturer instructed users about any necessary actions to be taken because of the lower test levels. This will be discussed in more detail later.

TEST PROCEDURES

EN 60601-1-2 provides requirements for emissions and immunity. The required emission test is EN 55011 (CISPR 11) Group I or II, Class A or B. Immunity test requirements are provided in IEC 801 and EN 61000-4-3, which are the so-called basic standards. Specific tests are explained in the following standards:

IEC 801-2:1991, for electrostatic discharge (ESD).

EN 61000-4-3 and IEC 801-3:1984, for radiated immunity.

IEC 801-4:1984, for bursts and electrical fast transients (EFTs).

IEC 801-5:1984, for surges.

IEC 801-2:1991—ESD. This standard requires contact- and air-discharge testing. EN 60601-1-2 set up a requirement of ±3 kV for contact discharge and ±8 kV for air discharge since rise times and spectrums will differ as test levels change. The reliability of the air discharge presents another problem: temperature, humidity, and the approach speed of the loaded ESD tip can all influence the test. For this reason, contact discharge was included in IEC 801-2:1991, whereas only air discharge had been required in the 1984 version.

The test setup requires a horizontal coupling plane (HCP) of 1.6 x 0.8 m placed on a 0.8-m-high wooden table. The equipment under test (EUT) and cables must be isolated from the coupling plane by a 0.5-mm-thick insulation support. For indirect discharge, a vertical coupling plane (VCP) of 0.5 x 0.5 m must be used. The VCP must be parallel to the EUT at a distance of 0.1 m. Discharges must be applied to different positions of the coupling plane so that the four faces of the EUT can be completely illuminated. Where coupling planes are specified, they must be constructed from the same material (copper or aluminum) and same thickness (minimum 0.25 mm x 1 m2) as that of the ground reference plane (GRP). The HCP and VCP must be connected to the GRP via a cable with a 470-k resistor located at each end.

resistor located at each end.

For both indirect and direct discharge tests, 10 discharges of each polarity must be applied. Discharges must be applied directly only to those points and surfaces of the EUT accessible to personnel during normal use. This includes areas accessible to maintenance personnel. For contact discharges, the discharge electrode tip must touch the EUT before the discharge switch is operated. For air discharges, the round tip of the electrode must approach the EUT as quickly as possible without causing mechanical damage. After each discharge, the ESD generator must be removed from the EUT so that it can be retriggered. This procedure must be repeated until all discharges are completed.

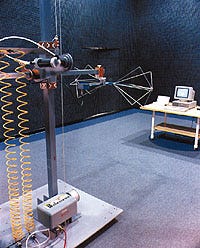

EN 61000-4-3—Radiated Immunity. This is the relevant basic standard for simulating the interference of transmitted electromagnetic waves to test for radiated immunity. The collateral standard requires 3 V/m from 26 to 1000 MHz, with an 80% amplitude-modulated signal. The modulation frequency must be within each functionally significant signal-processing passband. This often constitutes a severe test, because many devices—such as patient monitors with electrocardiocorder and electrocardiograph options—are more susceptible to amplitude modulation that falls within the range of frequencies used or sensed by the device for its normal function. For equipment that does not have a defined passband, the standard specifies 1-kHz modulation.

This test is usually done in an anechoic chamber. Special absorbant material (2 m in length) compensates for standing waves and reflections. The state-of-the-art standard for radiated immunity, IEC 61000-4-3, requires a uniform field of 1.5 x 1.5 m at a distance of 3 m, compared with 1 m required by EN 61000-4-3. The 3-m distance provides a more reliable test result.

IEC 801-4:1984—Burst/EFT. During testing, the bursts or EFTs should be coupled by using a coupling-decoupling network or by using a coupling clamp on the EUT cables. The coupling-decoupling network for an ac/dc main supply circuit allows the test voltage to be applied nonsymmetrically to the EUT's power-supply input terminals. The capacitive coupling clamp enables coupling of the fast transients to the circuit under test without any galvanic connection to the circuit terminals, cable shielding, or any part of the EUT. The clamp should be placed on a ground plane with a minimum area of 1 m2, and the ground reference plane should extend beyond the clamp by at least 0.1 m on all sides. The generator should be connected to the end of the clamp nearest to the EUT. EN 60601-1-2 requires test levels of 1 kV for plug-connected equipment, 2 kV for permanently installed equipment, and 0.5 kV for interconnecting lines longer than 3 m (i.e., lines using coupling clamps).

Manufacturers must determine whether a device creates a safety hazard as defined by IEC 60601-1 (Compliance Test Laboratories; Liberty, SC).

Manufacturers must determine whether a device creates a safety hazard as defined by IEC 60601-1 (Compliance Test Laboratories; Liberty, SC).

The test should last no less than 1 minute for each coupling point. Both polarities must be tested. For this test, high-voltage pulses are not the primary problem for the EUT. Problems can occur because of the very fast rise time of a single pulse, which can create a very high electromagnetic field.

IEC 801-5:1984—Surge. Although a surge is not a very fast pulse, it contains considerable energy. The surge test, according to IEC 801-5, is the most severe EMC test for medical device power supplies. The test simulates an overvoltage caused by switching and lightning transients, with a pulse coupled via a coupling-decoupling network on the power line of the EUT. The test voltage is 1 kV in differential mode with a 2- coupling resistor, and 2 kV in common mode with a 12-

coupling resistor, and 2 kV in common mode with a 12- coupling resistor. At least five positive and five negative discharges must be tested at selected points of the power supply. The pulse must be repeated at a rate of at least one per minute, and it is recommended to increase the test levels from 0.5–1 kV to 2 kV. The selected points should be 0°, 90°, 180°, and 270° of the sine wave. Because of the high energy level of this pulse, great care must be taken when performing this test. It is important to ensure that the generator is in a safe mode, especially during counter measurement or modifications.

coupling resistor. At least five positive and five negative discharges must be tested at selected points of the power supply. The pulse must be repeated at a rate of at least one per minute, and it is recommended to increase the test levels from 0.5–1 kV to 2 kV. The selected points should be 0°, 90°, 180°, and 270° of the sine wave. Because of the high energy level of this pulse, great care must be taken when performing this test. It is important to ensure that the generator is in a safe mode, especially during counter measurement or modifications.

FUTURE REQUIREMENTS

A revised version of IEC 60601-1-2 is currently being developed. This new edition is scheduled to be published this year but could be delayed depending on the comments received on the second draft and subsequent voting results. The changes from the first edition are expected to be extensive, with requirements updated to reflect the development of basic standards during the past 5 years. Performance criteria will change from being safety based to being based on continued utility of the device. Test levels will be increased for some tests, and additional tests will be required. Significant changes include a provision allowing emission tests to be based on CISPR/EN standards, such as EN 55013 for audio/video products, EN 55022 for information technology equipment, or EN 55014 for simple motor-driven devices (dentistry drills, for example). The requirements for harmonics distortion and voltage fluctuations according to EN 61000-3-2 and EN 61000-3-3 are also included in the draft version.

Major changes are also proposed regarding immunity testing. The failure criteria will be changed from its safety hazard focus to defined compliance criteria. The EUT must be fully functional, must be able to provide the intended clinical benefit, and must remain safe. The ESD contact-discharge level will be increased to 6 kV. Radiated immunity will require sweeps for all operating modes, and the frequency range will be 80–2500 MHz. Life-supporting equipment will require 10 V/m from 860 to 2500 MHz. To reduce test time, the modulation frequency will be either 1 kHz or 2 Hz, depending on the type of equipment. The differences between plug-connected and permanently connected equipment will be eliminated.

Test levels for the burst test will be 2 kV for main cables and 1 kV for input/output (I/O) cables, and patient cables will be excluded. If the EUT does not have a noise-protection component (a varistor, for example) to minimize surge, the test with the highest levels (1-kV differential mode or 2-kV common mode) will be sufficient. Conducted RF immunity testing according to EN 61000-4-6 will be added, with a level of 3 V from 150 kHz to 80 MHz. A magnetic immunity test with a level of 10 A/m will also be added, according to EN 61000-4-8. As required in EN 61000-4-11, voltage dips and interrupts with nominal line voltages of 0% Unominal for 0.5 periods, 40% Unominal for 5 periods, and 70% Unominal for 25 periods, and a separate test with restore-to-operation criteria at 0% Unominal for 5 seconds will be included. Additional disclosure requirements and warnings will be required for end-user documents. Information will be included in the "General Guidance and Rationale" annex of the revision to help manufacturers and test laboratories understand the requirements.

CONCLUSION

EN 60601-1-2:1993 can be difficult to use, and therefore has caused some confusion over how to conduct tests properly to meet the standard's requirements. A key example is correctly testing patient monitors, which often measure signals in the microvolt to millivolt range or the nanoampere to microampere range. Signals from the patient's body interact with radio frequencies, making it difficult for the monitor to discriminate signal interference. Another problem for performing the tests arises because of the response time for medical devices, which mandate a long dwell time for each frequency. The result is a long testing time.

Used to demonstrate compliance with the EMC Directive as well as with the MDD, EN 60601-1-2 has been in place for nearly 6 years. It is hoped that the current revisions will correct lingering problems like those described above. Innovative products and new technologies will certainly compel working groups and committees to continue to raise the bar for susceptibility test standards.

Harald Buchwald is EMC manager for MIKES Product Service GmbH (Strasskirchen, Germany).

Photo courtesy of CKC Laboratories (Mariposa, CA)

Copyright ©1999 Medical Device & Diagnostic Industry

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)