Assessment of Medical Devices Without Animal Experiments

To ensure patient safety, regulations such as the EU Medical Device Regulation require risk assessments to be conducted for all medical devices, including biological evaluation in accordance with ISO 10993. This article explores how manufacturers can have their products assessed efficiently without animal experiments.

Medical devices or their materials that come into contact with the human body during healthcare provision must fulfil their intended function without compromising patients’ health and safety. To avoid skin irritations and contact allergies, biocompatibility testing assesses the compatibility and interactions of a medical device with the surrounding body tissues. The ISO 10993 series of standards on “Biological evaluation of medical devices” plays a central role in this context. The ISO 10993-1 is a basic standard that defines the general approach to a biological evaluation within a risk management process.

The ISO 10993-23 standard (“Tests for irritation”) was added to the series in January 2021. This new standard defines principles for the assessment of medical devices and their constituent materials regarding their potential to induce irritation. The standard was separated from the ISO 10993-10 standard, which itself has applied exclusively to tests for skin sensitisation since late 2021. However, the general principles of the method are the same. Consequently, the tests for irritation also follow a step-by-step approach.

Identifying Threshold Values

In step one, all constituent materials—including any process aids or additives remaining on the product that were used during the manufacturing process—undergo chemical characterization in accordance with ISO 10993-18. The standard was last updated in 2020. In this update, the process flowchart was revised, and the significance of the analytical evaluation threshold (AET) emphasized. The AET value provides the basis for decision-making for chemical characterization and toxicological risk assessment. It also provides an indication of the level of sensitivity required of the method.

As part of approval, the supervisory authorities check whether the AET has been defined and observed. Identification of all constituent materials and determination of their specific thresholds are only possible with qualified and trained personnel and well-equipped laboratories. Manufacturers should therefore consult third-party laboratories to avoid drawbacks in the approval process, which are generally associated with high consequential costs.

Using Available Knowledge on Biocompatibility

It is the manufacturer's obligation to subsequently determine the chemical and physical properties of the materials and to collect information on the irritant potential. This may involve, for example, consulting suppliers or searching through the relevant literature. The ISO 10993-1 standard includes a possible approach to objective and reproducible research. In addition, data from previous applications and chemical databases can be used. Experts from independent third parties should be consulted to answer open questions. Broad expertise and many years of experience have proven to be useful in this context.

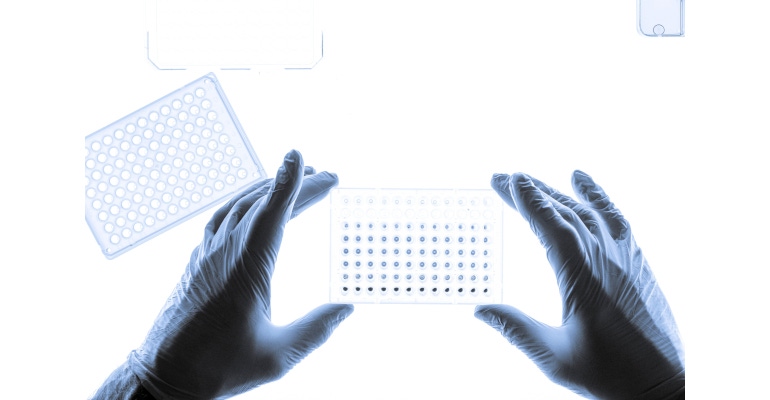

If the available information is insufficient for risk assessment in accordance with ISO 14971, a gap analysis can help to select suitable tests for obtaining the missing data. The applicable test strategies must always give preference to in vitro tests, for example in well plates, over in vivo tests.

Avoiding Irritation

As no scientifically validated in vitro test methods have been available to date, the irritation potential has mostly been determined by animal testing. Methods used for this purpose included subcutaneous injection of extracts of a medical device into rabbits. Now the ISO 10993-23 standard is the first to define a method based on reconstructed human epidermis (RhE). RhE models use normal human keratinocytes that are cultured in a well plate to form a multi-layered epidermal equivalent including dorsal, basal, and granular layers. The tissue is basically viable; together with the outer corneal layer of the epidermis (stratum corneum), it forms a barrier that prevents quick penetration of harmful substances.

While skin sensitization leads to delayed immune response in case of repeated contact with the foreign substance (allergy), irritation is a direct and localized reaction. It is caused when an irritant migrates from the epidermis to the underlying dermis, where it may cause redness of the skin (erythema) and tissue swelling (oedema). In the test method using RhE models, a dye (MTT) that changes color in the mitochondria of living cells is added to the test extract. Once the test substance has been applied to the model, the change in color can be determined and quantified with the help of UV/VIS spectroscopy. This enables the proportion of living cells in the sample—in other words, cell viability—to be determined. By using the defined threshold values, the test substance’s potential to cause irritation can be evaluated.

Conclusion

An international study confirmed the applicability of two types of models, which the OECD validated for hazard identification of chemicals. Under the new ISO 10993-23 standard, the RhE-based method is a reliable alternative to animal experiments in many test scenarios. No validated in vitro test methods are yet available for sensitization testing in accordance with ISO 10993-10. However, gap analyses and the expertise of third-party testing laboratories such as TÜV SÜD help manufacturers organize their available knowledge and draw up a test strategy that reduces the number of necessary tests.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)