How J&J Is Closing Gaps in Patient Safety

J&J's Medtech CMO joins Let's Talk Medtech to discuss patient safety and reducing the risk of avoidable harm in medical devices.

April 7, 2022

At some point or another, all of the tier 1 medical device companies, including Johnson & Johnson, have had to deal with device-related patient safety concerns.

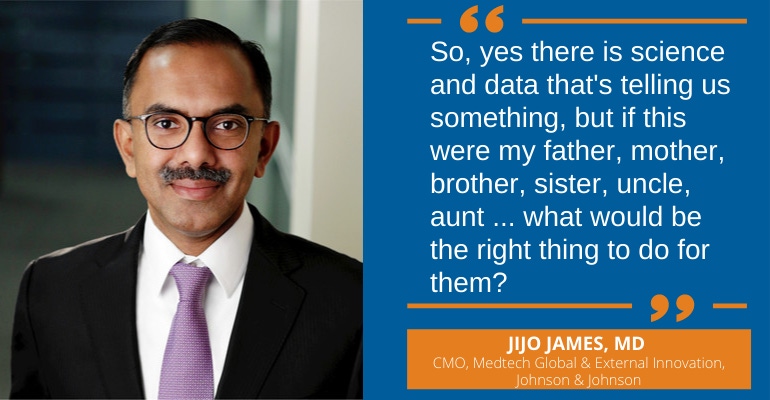

In recent years, however, the company has seen a shift from a reactive approach to medical device-related patient safety issues to a more proactive approach. Jijo James, MD, chief medical officer of medtech and global external innovation at Johnson and Johnson, joins us this week in the Let's Talk Medtech studio to discuss this trend, and how J&J is trying to close gaps in patient safety.

Episode 39 transcripts

Amanda Pedersen:

Welcome to Let’s Talk Medtech. I'm Amanda Pedersen, filling in for Omar, and here with us today talking about the very important topic of patient safety is Dr. Jijo James, chief medical officer of medtech and global external innovation at Johnson & Johnson.

Okay Jijo, Let's Talk Medtech. How has the conversation around patient safety in medical devices evolved over the course of your career?

Jijo James, MD:

Definitely the conversation around patient safety has evolved over the past decade plus where we moved from a largely reactive approach to patient safety, you know, an event happens and evaluate what it happens and what changes need to happen, to a more proactive one where we are trying to close those gaps to ensure that those who use our products are free from any kind of avoidable harm. And I say avoidable because there's a benefit-risk to everything, right? There is risk associated with any procedure, and it's important to balance that out and ensure that the benefits far outweigh those risks.

So, what do I mean by proactively managing risk? It's ensuring that we've got good governance and procedures in place. It's ensuring you've got safety standards. We've got bodies called the safety management teams that are led by physicians that evaluate a safety issue with the ability to escalate to medical safety counselors [when] appropriate we've got active post-marketing surveillance in place, we've standardized the whole health hazard evaluation, the harms, the coding of adverse events, we've established benefit-risk frameworks, but all that ensures that through the design process you're creating a safe device. But we also need to understand that just doing that by itself does not help ensure patient safety because there is an operator in the middle who utilizes that device, right?

Amanda Pedersen:

Ah, and that's the crux of it, right? You've got a human user at the end of all of that work to reduce risk in the design process, and in the development process, and then you have to trust the end user to use it in the safest way possible. Whose responsibility does that fall on? Is it the users, the physicians using the device? Or is it the company that makes the device?

Jijo James, MD:

Our responsibility extends even in that space to understand how we can have surgeons utilize our devices better, and how we can integrate that approach into our stage gate So we do things like timely, relevant, use-related safety training so that our sales force is trained on that particular device to know what are the things that they should highlight specifically to the surgeon, what's different between this iteration of the device and the previous one. As you know, medtech to a large extent development is an iterative process. So, as a surgeon looks at the device – if I could almost draw parallels to, you know, we buy multiple televisions in our lifetime and our expectation is that you click the button, and the TV turns on. Physicians and surgeons are used to using devices and iterations on it, they expect it to kind of work the same way the previous version of it worked. But there may be certain new aspects that you need to highlight to them that may be different. So that's the trust program that we have.

Similarly, along that way we have tools called the optimized device performance tools. Again, every device goes out with the instructions for use, if you've seen some of those, they're kind of the size of a small booklet. What can we do to enhance the messaging in those so that you're creating maybe some kind of a foldout that highlights specific things they need to know about that device. So again, not just ensuring that you're developing the safest devices, but ensuring that they are used in the most appropriate way to drive the best outcomes possible, and then kind of going a step beyond that to furthering the science.

And there we've got programs, what can we do collectively for the ecosystem, right? How can we create a collaborative community where we are all – as industry, as academia, as regulators – focused on driving the best outcomes? And two initiatives out there that we worked on, one is in ensuring that the company's clinical trial data is available to scientists the world over if they want to use that data to promote scientific research and serve public good. And that's done through a partnership with Yale, a partnership called the Yale University Open Data Access project, or Yoda, and the other one is Ariadne Labs, which is a collaboration between Brigham Women’s and the Harvard School of Public Health where, modeled on the WHO safe surgery checklist, we've created something called the device briefing tool that's meant to encourage communications within the operating team. Because we strongly believe that if you can encourage communications within that team, you help reduce risk in that procedure.

So just as flavor of you know, where in the past we used to look at complaints data and then react to that, how we are pivoting to be more proactive and trying to prevent events from happening, and then closing the loop back based on what we’re learning to drive better iterative design while supporting the surgeons in the middle.

Amanda Pedersen:

So, despite all of those efforts and best practices and all of the things that you've just mentioned we know that at one time or another all of the tier one medical device companies including Johnson & Johnson have had to deal with device related safety concerns. Can you share any lessons learned from J&J's experiences with these issues, and anything that might help other medical device companies be better equipped to handle these issues when they do arise?

Jijo James, MD:

Sure. You are right, Amanda, all of us face recalls at some point or the other despite all the efforts that we take to ensure that we have the safest devices out there. And the recalls could be efficacy related, they could be risk related, things that you learn in the real world, right? And our aim is always to try and reduce those numbers year-on-year, but there is a certain percentage that inevitably happens despite best efforts. So again, our principle out here just based on what we've learned is two-fold. No. 1, to always lead with the science and the data, look at what the science and the data is telling us, leave our opinions/perceptions/biases at the door, and look at what the data is leading us to. And No. 2, to keep the patient at the center, putting people first, using an ethics and values-driven lens. So, yes there is a science and data that's telling us something, but if this were my father, mother, brother, sister, uncle, aunt, you know place whoever you want to place in the middle, what would be the right thing to do for them? I think those are the two key principles that guide all of our safety-related decision making within the company and are very well aligned with the J&J credo.

In addition to that we also believe that it is important to be proactive and transparent, right? Now, what do I mean by that? We today have access to real-world data where we can begin to scientifically answer a lot of these questions much better than we were able to do let's say about five years ago. If I were to give you a very generic example, say you've got a device that is being used globally and in one particular market you begin to receive complaints about breakages with that device, for example. You go through your whole safety management process and you're really not able to put a finger on why that breakage is really happening. You go down to the site, you visit the site, and you, again potentially discover that maybe the device is not being used appropriately per the instructions for use. Maybe they're doing something different that's leading to those breakages. You're now in a situation where you believe it could be a use-related error but, again, you're going to be perceived as coming from a biased point-of-view because it is your device, right? At the end of the day, you're always going to be seen as trying to protect your baby, your child, you're going to be seen coming from the perspective of you don't want to see a blemish on your child so you're going to do everything to protect the child, and that's pretty much going to be the way the regulator is going to look at it as well. If the regulator is hearing something from an academic institution and gets additional information from a manufacturer that runs counter to what the academic is telling them, my natural bias even as a regulator would be to side with the with the academic institution based on their real-world experience, right?

So again, when you're in a situation like this, it is always important to go back to the data and see what the data is doing. Maybe go ahead and design a real-world study, look at what the real-world evidence is showing you around that device. And when I say design a study, I'm saying design the protocols, be very clear about the endpoints that you're looking at, be transparent and publish that protocol before you go ahead and execute the study, and then based on that science and data you probably have a much better standing to understand what's going wrong with the device, if something truly is, or whether this is truly a use-related error.

And then lastly, irrespective of where the fault lies, even if it is a use-related error, go back into the design process and figure out, what can I do to weed that error out? What can I do to ensure that in the design that these surgeons don't make that error irrespective of how they might choose to use the device? Those are some of the principles that we've used at Johnson & Johnson very effectively to address some of these challenges.

Amanda Pedersen:

Now Jijo, I understand that you're also the board chair of the medical device innovation consortium, or MDIC for short. So, what kind of work is the MDIC doing to advance patient safety in healthcare?

Jijo James, MD:

Yes, I was honored last year to be appointed as the chair of the board of directors for MDIC, and I had served on the board for four years prior to that. The MDIC as you know – as you probably know – is the first public-private partnership that brings together representatives from government, academia, not-for-profit patient groups, and industry in this collaborated community that's aiming to drive regulatory and safety science for patient benefits. We are working in this pre-competitive space for patient benefit. And you know some of our work in 2021, for example, reflects our passion to put patients at the center of what we're doing.

What do I mean by that? We've hosted workshops to introduce payers and health technology assessors to patient preference information and its value in making coverage decisions so that patients are able to utilize the technologies that have been approved by the regulators. We worked in developing the science of patient input resources to help manufacturers communicate with patients better and to maximize patient input through the pandemic. We've created expert guides that patients can use to figure out, ‘How do I balance that benefit-risk I need to get a procedure done? How critical is it that I get it done now versus can I wait?’ in the context of a pandemic what are my benefits? How should I think about that?

We house the national evaluation system for health technologies, NEST short, that is helping create the electronic infrastructure backbone that can help us use real-world data better, not just for product approval so we can get innovation to market faster, but also for active surveillance so that we can see how that invention is performing in the market.

So, a lot of initiatives that are underway, exciting initiatives underway, focused on patient benefit.

Amanda Pedersen:

That's it for this episode of Let’s Talk Medtech. Thanks again to our guest, Dr. Jijo James, you can find him on LinkedIn. And visit us at www.mdionline.com for all of your medtech news. Make sure to rate, review, and subscribe to us on Apple Podcasts, or wherever you get your podcasts.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)