World's Smallest 3-D Lattice Boasts Serious Strength

February 16, 2016

A new 3-D printed lightweight construction materials inspired by the structure of human bones can withstand tremendous pressures.

Kristopher Sturgis

Developed at the Karlsruhe Institute of Technology (KIT), new lattice-based structures can withstand unbelievably high pressures -- approximately 1.2 billion newtons per square inch. This equates to about 12,000 times the pressure of the atmosphere.

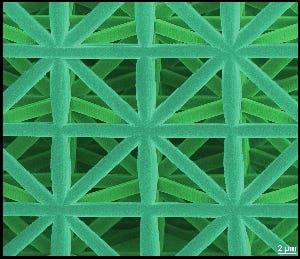

It can be used as load-bearing supports in a variety of different materials. The new lattice structures are roughly 10,000 nanometers across -- a size so miniscule you could line up at least 150 of them on the head of a pin.

"We have shown that fairly weak polymeric microlattice structures, which are fabricated by high-resolution 3-D printing, can be transformed into ultra-strong carbon nanolattices by pyrolysis, a heat treatment in vacuum," says Jens Bauer. Bauer is a researcher at KIT and is the lead author of the study creating new lightweight construction materials found in nature.

Bauer says that during pyrolysis the polymer turns into a glassy carbon, shrinking the microlattice structures significantly. The end product is the world's smallest 3-D lattice structures produced to date, an achievement that also provides these tiny structures with unprecedented strength and stability.

"The glassy carbon reaches the fundamental limit of theoretical strength, which is given by the strength of the atomic bonds," Bauer said. "Thus, with the entire structure being as strong as high-strength metals at half the density of water, diamond is the only bulk material which attains notably higher ratios of strength-to-density."

On top of its incredible strength, the lattice was also designed to be highly conductive, enabling it to be useful as an electrode in a range of electrical equipment. Researchers say the structure can even be classified as a type of "metamaterial," a specific kind of material engineered to have properties not found in nature. These unique properties are what could expand the use of the microstructures into a wide range of applications.

"Applications related to optical, electrical, and thermal effects will be of high interest," Bauer says. "Glassy carbon has unique electrical properties, high thermal and chemical resistance, and is also biocompatible. Due to the latter, it may be interesting for micro-implants in the line of micro stents or something similar."

Bauer says that the electrical conductivity component of the microstructures could open up some interesting avenues for various medical applications. He even believes it could potentially be used as an electrode material in batteries. The group also noted that these microstructured materials are often used for insulation, or as shock absorbers. Open-pore materials could even be applied as filters in chemical industry.

For now Bauer says the project remains in the lab state, as he and his colleagues look to explore different applications and upscale production of the structures.

"The future challenge will be to scale-up the process to fabricate larger material volumes for practical use," he says. Once larger material volumes are achieved, these microstructures could be used in a variety of different products and devices.

Continue>>

Learn more about cutting-edge medical devices at BIOMEDevice Boston, April 13-14, 2016. |

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)