Working Around COVID-19 Challenges to Get New Products to Market

A medtech company discusses the challenges faced when launching a non-COVID-19-related product during the pandemic.

February 2, 2021

Yet another fallout from 2020 and the COVID-19 pandemic has been the difficulty in getting a new, non-COVID related product to market, shared Brad Greer, CEO of DrySee, a manufacturer of a patented non-invasive liquid indicator gauze technology for wound care. He reported to MD+DI a number of issues the company has had to contend with, which have led to new approaches to production and distribution.

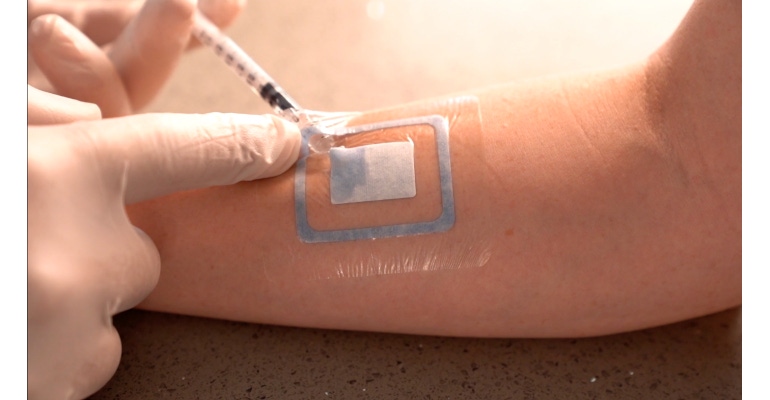

DrySee makes a patented breathable waterproof covering, with a water invasion indicator near the edge and center of the bandage that lets a patient know whether their wound is free from liquid contamination. If there is contamination from external sources or fluid from the wound site, the liquid indicator changes color, which alerts the patient that it is time to change the bandage. According to the company, DrySee bandages can replace virtually any waterproof dressing in virtually every application. Therefore, DrySee allows patients to shower immediately post procedure with confidence.

Greer said that DrySee made 100,000 units that were ready to go by September 2020. “But COVID changed everything,” he said. In fact, he said, many wound-care manufacturers postponed new product introductions and product improvements in 2020.

“Distribution has [also] been disrupted with COVID because it's masks, gowns, gloves,” Greer explained “Manufacturers, too. 3M is focused on N95 and PPE, and their successful integration of Acelity. So a lot of things were shelved,” he said.

So companies have been seeking new ways to overcome these challenges. Greer cited an example of the wound-care company, MicroMend, which changed its distribution methods. “In Q1 2020 they were approximately 80% B to B and 20% B to C,” Greer said. “When I say B to C, I mean direct to consumer or patient or clinic via Amazon.” Because of distribution problems due to the pandemic, MicroMend flipped its model up to 80% direct to customer this year, Greer explained.

DrySee has adopted this solution as well. “We have an excellent Amazon store managing group that we’re partnering with to make this change happen,” Greer said, noting that in order to make this most effective, they had to switch its web development firm to one that was savvier in terms of e-commerce and selling product.

The company is also kicking off product sales with current and additional distributors in the United States as well as globally. DrySee has had discussions with Cardinal Health on a potential partnership to manufacture or private label the product and is in the process of conducting a clinical trial for them, he reported. “We've got a couple of candidates [for the study] including Houston Methodist, which is the second largest integrated delivery networks (IDN) here in Houston,” Greer said. DrySee has also met with McKesson for distribution.

DrySee has launched a product trial campaign with physicians and surgery centers to gain brand awareness, gather feedback, and testimonials. The company’s Phase 2 products will include high-absorbency foams and antimicrobials, which will be ready to sample in Q2 2021.

Despite some initial struggles, Greer said that DrySee is on the right path. “Sometimes you grow out of your training wheels and need a little bit more speed and you're cycling, if you will, and that's what we've done there. So, yes, many challenges but we’re working around them and making success, progress, and sales.”

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)