Packaging 14881

March 8, 2004

Originally Published MPMN March 2004

SPOTLIGHT

Packaging

Pouch opener

A pouch-opening unit acts as a third hand for the operator, automatically presenting an open package. The QuickPouch handles packages measuring 21¼2-8 in. wide and 4-12 in. tall. With an adjustable rate of up to 15 pouches per minute, the product accommodates materials such as foil, Tyvek, paper, and other laminates. Quickpouch, Ronkonkoma, NY; www.quickpouch.com

A pouch-opening unit acts as a third hand for the operator, automatically presenting an open package. The QuickPouch handles packages measuring 21¼2-8 in. wide and 4-12 in. tall. With an adjustable rate of up to 15 pouches per minute, the product accommodates materials such as foil, Tyvek, paper, and other laminates. Quickpouch, Ronkonkoma, NY; www.quickpouch.com

Top-sealing system

A packaging system is designed to seal uncoated top webs to a number of different forming films in horizontal form-fill-seal applications. The use of a universal top-sealing plate minimizes changeover time by eliminating the need for changing that element of the station. Tiromat Medical Packaging, Biedenkopf-Wallau, Germany; www.tiromatmedicalpackaging.com

A packaging system is designed to seal uncoated top webs to a number of different forming films in horizontal form-fill-seal applications. The use of a universal top-sealing plate minimizes changeover time by eliminating the need for changing that element of the station. Tiromat Medical Packaging, Biedenkopf-Wallau, Germany; www.tiromatmedicalpackaging.com

Multilayer packaging

A multilayer coextruded structure is engineered to contain iodine and other hard-to-hold liquid compounds. The IR300 packaging material is a paper, polyethylene, and aluminum foil composite, topped with a layer of the company's FortéG polyester sealant. Suitable for alcohol swabs, prep pads, and liquid medical applications, the material does not require a tear notch to gain entry. The material also offers stiffness and a coefficient of friction between the sealant and the swab material. Rollprint Packaging Products Inc., Addison, IL; www.rollprint.com

A multilayer coextruded structure is engineered to contain iodine and other hard-to-hold liquid compounds. The IR300 packaging material is a paper, polyethylene, and aluminum foil composite, topped with a layer of the company's FortéG polyester sealant. Suitable for alcohol swabs, prep pads, and liquid medical applications, the material does not require a tear notch to gain entry. The material also offers stiffness and a coefficient of friction between the sealant and the swab material. Rollprint Packaging Products Inc., Addison, IL; www.rollprint.com

Orbital carton erector

Featuring a balcony design, a cartoner provides maximum access to the drive components from one side of the machine. The P100 orbital carton erector processes cartons at speeds of up to 350 pieces per minute. Suitable for three shifts per day, the system has digital gauges and scales with pointers that enable a no-tool changeover within 10 minutes. Serpa Packaging Solutions, Visalia, CA; www.serpapackaging.com

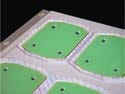

Carrying case inserts Custom-designed case inserts protect and organize products. Offering inventory control, security, and aesthetics, the products are available in a variety of materials, such as molded and fabricated foams, thermoformed plastics, laminated composites, and conductive materials. Inserts are CNC machined, with one-piece construction for durability and multiple cavity depths. UFP Technologies, Georgetown, MA; www.ufpt.com

Custom-designed case inserts protect and organize products. Offering inventory control, security, and aesthetics, the products are available in a variety of materials, such as molded and fabricated foams, thermoformed plastics, laminated composites, and conductive materials. Inserts are CNC machined, with one-piece construction for durability and multiple cavity depths. UFP Technologies, Georgetown, MA; www.ufpt.com

Electron-beam sterilization E-beam irradiation sterilization is available for manufacturers and marketers of single-use medical disposables. Using high-energy electrons, E-beam sterilization eliminates the need for radioactive material sources, with no refueling, handling, or downtime required. Penetrating E-beam irradiation permits flexibility in working with mixed-density loads and any shipment size. Precision dosing leaves no residual radiation or chemical and moisture residue to degrade products or impact packaging. E-Beam Services Inc., Cranbury, NJ; www.ebeamservices.com

E-beam irradiation sterilization is available for manufacturers and marketers of single-use medical disposables. Using high-energy electrons, E-beam sterilization eliminates the need for radioactive material sources, with no refueling, handling, or downtime required. Penetrating E-beam irradiation permits flexibility in working with mixed-density loads and any shipment size. Precision dosing leaves no residual radiation or chemical and moisture residue to degrade products or impact packaging. E-Beam Services Inc., Cranbury, NJ; www.ebeamservices.com

Band and sleeve applicators

Band and sleeve applicators

Heat-shrink, tamper-evident, full-body sleeve applicators are available in water- and dust-resistant versions. The EZ-100SP model features an enclosed film roll compartment to minimize entry of dust or waterborne contaminant particles. Manufactured with an all-stainless-steel enclosure and frame, the product processes containers ranging from 1¼3 to 2 3¼4 in. in diameter, with a lay-flat film width of 15 to 112 mm. When processing films with thicknesses of 40-70 µm, tamper-evident bands can be applied at 150 containers per minute, and full-body sleeves at a rate of 80 per minute. The machine also includes a motorized film unwind system, product size changer, and front or rear access to the film supply. Axon Corp., Raleigh, NC; www.axoncorp.com

Component packaging

Component packaging

An elastomer gel material provides a tacky, nonadhesive surface to hold small parts in place during transport without the need for pockets or custom-molded packaging. The Gel-Box carrier is an integrated box system suitable for handling medical components to be removed manually with tweezers, forceps, or by hand. The packaging is EtO and gamma compatible and can accommodate an array of device shapes and sizes. Gel-Pak, Hayward, CA; www.gelpak.com

Pouch sealers

Pouch sealers

Designed to meet cleanroom packaging requirements, two precision medical pouch sealers are suitable for a number of premade packages. The PM EL 18 and PM PLC 18 are both constant heat-validatable jaw sealers featuring 18-in. seal bar lengths and 3¼8-in. seal widths. The machines also offer stainless-steel enclosures and process alarms for temperature. Four temperature validation ports enable profiling and monitoring across the entire seal bar. The PM PLC offers system alarms for temperature and pressure, which disable the machine when it is out of specified tolerances. Belco Packaging Systems Inc., Monrovia, CA; www.belcopackaging.com

Rollstock equipment

Rollstock equipment

Contoured packaging and card placement are available options with two rollstock machines. Offering a form-fill-seal combination, the systems minimize scrap and help maximize production speed. The R530 thermoforming system uses roll-fed plastic to create blister and sheet-fed backings for high-volume operations. The R240 system is an option for small- and mid-sized processors. The machines are suitable for disposable products, such as syringes, vials, connecting sets, and catheters. Using a touch screen program, the packaging equipment saves user preferences, such as package depth or hole punches, in memory and enables quick changeover for the production of multiple designs. Multivac Inc., Kansas City, MO; www.multivac.com

Adhesive packaging

Adhesive packaging

A variety of adhesive packaging is available in sizes from 1 to 1000 g. Suitable for holding reactive adhesives, sealants, or resins, package types include A-Pak flexible burst-seal and divider-clip pouches, dual cartridges, and Semkit packages. The company's services include blending and compounding of material according to the customer's specifications. Adhesive Packaging Specialties Inc., Peabody, MA; www.adhesivepackaging.com

Copyright ©2004 Medical Product Manufacturing News

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)