Prosthetic Vein Valve Goes with the Flow

November 1, 2008

R&D DIGEST

|

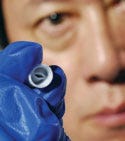

David Ku provides an up-close look at the valve. |

Collaboration five years in the making at the Georgia Institute of Technology (Atlanta) has led to a promising prosthetic vein valve. The device may replace nonfunctioning valves in patients suffering from chronic venous insufficiency, a condition that occurs when veins can't pump blood back to the heart.

“Blood flows to the toes because of gravity, but the body uses vein valves to pump blood back to the heart,” said David Ku, professor of mechanical engineering at Georgia Tech. “However, sometimes a vein valve dissolves after a clot. The loss of the valve leaflets allows blood to flow the wrong way, causing swelling in the legs and ankles.”

Current treatments for chronic venous insufficiency include anticoagulant therapy, compression hosiery, and a valve transplant. Because it's not easy to find an appropriate valve in a patient's leg, a prosthetic valve could be a more-effective alternative.

The prosthetic valve has a one-way flap composed of a Georgia Tech–patented material called poly(vinyl alcohol) cryogel. The material provides mechanical strength for human tissue replacement, it's more flexible than body tissue, and its attraction to water enables biocompatibility with natural tissue.

|

(Left to right) Georgia Tech professor David Ku, former graduate student and consultant Harris Bergman, and current graduate student Prem Midha test the valve for the formation of clots using a pump system. (GARY MEEK/GEORGIA TECH) |

After finding typical valve-testing methods inadequate, the researchers created their own test techniques to examine how the valves would perform long term. To make the device as close to the real thing as possible, they devised tests that showed that the valve could withstand high pressures (more than 500 mm of mercury) without leaking. They also made sure that the prosthetic vein could open with a pressure gradient of 2.6 mm of mercury.

Laura-Lee Farrell, a former Georgia Tech graduate student, devised one method to examine the possibility of blood clot formation inside the valve. After 120 minutes of blood flow, the valves stayed open without clots. The results demonstrated that the valves had low flow resistance and resistance to fatigue.

The team's plan is to test the valve's biocompatibility and performance in sheep. Other members of the prosthetic valve team include Rudy Gleason, assistant professor of mechanical and biomechanical engineering at Georgia Tech; Ross Milner, assistant professor of surgery at Emory University (Atlanta); former Georgia Tech graduate student Harris Bergman; and current graduate students David Bark and Prem Midha.

Their work has been funded by the Wallace H. Coulter Foundation and the National Collegiate Inventors and Innovators Alliance.

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like