WELDING AND SEALING

June 1, 1998

WELDING AND SEALING

Plastics assembly system

An ultrasonic plastics assembly system incorporates a generator, process controller, and multiplexer network in one unit. The Dynamic Process Controller (DPC) uses a powerful 32-bit RISC microprocessor that allows the user to program and regulate all assembly cycle parameters that affect ultrasonic plastics assembly—time, energy, distance, peak power, force, velocity, frequency, and amplitude. The DPC samples the cycle parameters 1000 times per second to provide greater accuracy, consistency, and control during plastics assembly processes; it can process more data in less time, making assembly more efficient and reliable. Dukane Corp., Ultrasonics Div., 2900 Dukane Dr., St. Charles, IL 60174.

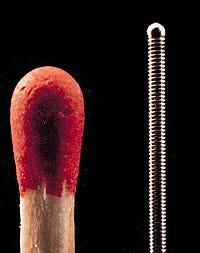

Microarc welding

A power supply designed for plasma and tungsten inert gas (TIG) welding provides an affordable alternative to laser or E-beam welding systems. The Plasmafix P&T power supply offers low amperage capabilities to 0.1 for plasma welding and 0.6 for TIG welding. It can be used for welding ball ends on wire, small-diameter wire rounding, precision component assembly, and medical instrumentation welding applications. The manufacturer also offers a range of welding peripherals and custom-designed systems. Process Welding Systems, 601 Swan Dr., Smyrna, TN 37167.

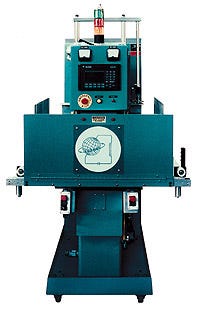

RF sealers

PLC-controlled radio-frequency sealers with automatic power control monitor and adjust the power settings for both the 360° tube seal and the perimeter seal in real time. The operator interface features preprogrammed job settings based on historical records and the ability to download production results to a PC for documentation purposes. On-screen diagnostic message capability is also built into the system. Cosmos Electronic Machine Corp., 140 Schmitt Blvd., Farmingdale, NY 11735.

RF generators

A company provides a family of small, versatile RF generators that power either handheld or bench-mounted pneumatic sealing and welding heads. The generators can easily and efficiently seal or weld tubing, luers, fittings, hubs, and bags, or can be used in custom applications. The operator can control RF power and dwell time either automatically by computer or manually via the easily accessible front panel. The tube sealer or welder is suitable for closed plastic systems for medical and biologic processes including synthetic cell and tissue processing and research, therapeutic blood processing units, sterile water or intravenous systems, and culture media processing. Each RF generator is configured with interchangeable plug-in generator and sealing head modules that take just minutes to replace. SEBRA, 500 N. Tucson Blvd., Tucson, AZ 85716.

Ultrasonic welders

A new line of ultrasonic welders features an expanded reactive welding system that supplies the exact amount of ultrasonic energy to finish the weld, regardless of dimensional variations of the part or welding mode used. The most sophisticated model in the Omega III series, the MCX offers the quality management and precision required for medical device welding applications. It features a large display screen and can weld using four different modes: constant time, where the actual weld cycle time is programmed into the MCX and is consistent each time; constant height, where a constant stack height is maintained from part to part; constant travel, where the actual melt travel is measured and kept constant, allowing for part variations; and constant energy, where the welder supplies exactly the same power to each weld. Additional features include simplified programming and machine adjustment, a large work area around the application, good amplitude control, and an optical encoder. A proportional valve allows trigger, weld, and cooling pressure to be controlled separately during the weld cycle, reducing weld time and increasing weld integrity. The MCX is available with welding frequencies of 20 or 30 kHz and power supplies ranging from 800 to 3000 W. Forward Technologies Industries Inc., 13500 County Rd. 6, Minneapolis, MN 55441.

Custom welding systems

A company builds custom systems for welding devices such as catheter guidewires, orthoscopic cutting tools, implantable battery devices, heart valves, biopsy needles, and other sensitive, precision devices. The quality-conscious contract welding division accepts long or short production runs. A free evaluation of a customer's sample application is offered. Weldlogic Inc., 2550 Azurite Cir., Newbury Park, CA 91320.

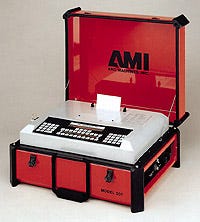

Power supply

A power supply/controller is capable of welding tubing and thin-wall pipe. The Model 207 machine produces welds that meet or exceed the requirements of medical device applications. Up to 100 different welding schedules can be stored in its memory for rapid access. High-integrity, sanitary welds are easily reproduced at the touch of a button. The microprocessor-controlled power supply is available in 100- or 150-A versions with a two-year warranty. Arc Machines Inc., 10280 Glenoaks Blvd., Pacoima, CA 91331.

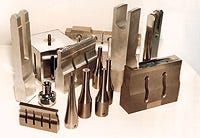

Ultrasonic horns

A company designs and builds specialty medical ultrasonic horns and fixtures. The ATC line of 35- and 40-kHz tungsten carbide–faced horns are suitable for medical applications that require repeatable weld performance—such as small or delicate parts—over long production runs. The horns demonstrate longevity on abrasive materials for small-weld-surface applications. The Acoustical Tooling Co., 8408 Wilmette Ave., Darien, IL 60561.

RF welding machinery

RF welding machinery with built-in turntable systems can process pre-die-cut, silk-screened, foil-stamped, and roll-fed materials. The systems are flexible and modular, featuring automatic feeders that can be moved to different turntable positions or moved to another turntable. This flexibility provides labor savings and increases capacity. Safe and easy to operate by one person, the welding systems are fully tested before leaving the factory. Technicians are available to train operators and maintenance personnel. Hall Dielectric Machinery Company, Inc., 420 Bryant Blvd., Rock Hill, SC 29732.

Desktop laser welder

A compact, self-contained laser system is designed for precision welding and micromachining. The EDW-15 is half the weight and practically half the size of comparable systems, according to the manufacturer, making it suitable for desktop welding. Running on 115-V-ac wall current, the system delivers 15-W output and requires no external cooling. The application-specific fiber-optic delivery system (available in either 200 or 365 µm) allows highly precise microprocessing on a very small scale. The user-friendly welder comes equipped with a microprocessor-based control unit with a large, easy-to-read LCD. Variable pulse widths from 0.2 to 10 ms are achievable in single shot, burst, and repeat rates. Accurate application of the laser beam is facilitated by a visible light aiming feature. The workstation and related accessories include a focusing head, gas-handling system, viewing optics, and computer-controlled translation stages. Typical applications include spot welding for hard disk suspension, electrical contacts, and relay armatures; seam welding for pacemaker housings and electronic packages; and reflow soldering of flexible circuit boards. Equilasers Inc., 536 Weddell Dr., Ste. 6, Sunnyvale, CA 94089.

You May Also Like