Water-Jet Cutter Requires Minimal Training

September 1, 1999

Manufacturing Equipment

Water-Jet Cutter Requires MinimalTraining

Suitable for short-run parts

COMBINING A MOTION CONTROLLER, high-pressure pump, abrasive jet delivery system, and two-axis machining table, the JetMachining Center from Omax Corp. (Auburn, WA) is designed for the production of precision parts.The system cuts nonconductive, reflective, and hardened materials and can perform CNC mill cutting and boring. Finished parts are free of burrs, stresses, and heat-affected zones.

The unit's motion control system combines CAD/CAM and motion control software to facilitate complex part machining using automatic tool path creation and a built-in cutting model. Icon-driven menus and on-line assistance make this system suitable for users with minimal training. Optional software modules include Nester LT for nesting complex parts and Translator for translation of a variety of CAD formats.

Tool paths are entered into the top-mounted, IBM-compatible computer and then sent to the abrasive jet delivery system, which accelerates prepressurized water through a small sapphire jewel within the self-aligning nozzle at 2500 ft/sec. An abrasive is mixed with the water in a ceramic tube, and a stream of abrasive-laden water exits the nozzle at 1000 ft/sec.

Mounted to the cutting table is an x-y-axis whose drive mechanisms include tool-grade linear bearings, brushless servomotors, and high-precision ball screws.

For more information, call Omax Corp. at 800/838-0343.

Product Development

Automatic Writing Device Draws Thick-Film Electrodes

Features a pen that 'floats'

ARE YOU A MAKER of dc-heater-type cauterizers who is looking for more uniform product performance and higher manufacturing yields? The MicroPen precision writing system from OhmCraft Inc. (Honeoye Falls, NY) may help you reach your goals. MicroPen automatically draws thick-film electrodes in uniform widths as small as 2 mil and as thick as needed. No hand operations or hard tooling are involved.

Under CAD control, MicroPen performs dependably on substrate materials ranging from metal to ceramics to glass. Substrate configuration and fragility don't present problems. A patented dynamic pen control arrangement causes the pen to actually float on the line it's writing. This means that multiple layers of conductor and dielectric can be drawn before a single firing. The long-nosed pen can draw lines within grooves, over surface irregularities, and in helical patterns on cylindrical probes.

When developing new products, designers need only change computer instructions to make incremental changes in conductor patterning and line dimensions. After a single firing, the series of prototypes can be tested with the assurance that their performance will be identical to that of the production units, since the same process is used for manufacturing.

For more information, call OhmCraft Inc. at 716/624-2610.

Materials

Polymer Meets Needs of Implant Products

Designed for long-term implants

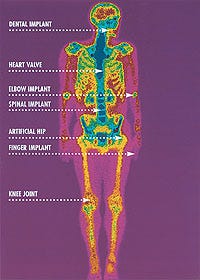

MEDICAL OEMs now have an advanced biomaterial to specify in implant products and other high-performance applications.

Designed to meet stringent medical product performance criteria, PEEK-Optima LT polymer is the newest member of the PEEK polymer family of polyaryletherketone resins from Victrex USA Inc. (West Chester, PA). Compared to other plastics available for this market, PEEK-Optima LT polymer is stronger, can stand up to more aggressive environments, performs better in steam, and maintains impact properties over a broader range of temperatures, according to Victrex.

Since the company tailors the stiffness of the polymer to match that of human bone, the material can be used in long-term applications such as hip, spinal, and dental implants. In addition, the polymer's inherent lubricity helps prevent implants from cavitating on the bone, which is especially important for hip implants.

PEEK-Optima LT can fill very thin walls in products such as heart valve components. Because of its combination of strength and stiffness, manufacturers can use less of it than other plastics to achieve the same stiffness, Victrex claims.

For more information, call Victrex USA, Inc. at 800/842-8739.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)