Spotlight on Rapid Prototyping

January 1, 1998

Spotlight on Rapid Prototyping

Stereolithography molds

Stereolithography molds can be built quickly and with less expense than molds made by traditional methods. The process is similar to building stereolithography parts, but the mold is reinforced to withstand injection molding conditions for 50 or more cycles. Although they may not be as attractive asparts from other prototyping methods, parts produced from stereolithography molds canbe used to verify part design and functionality in many specified materials, including polycarbonate, ABS, polypropylene, and polystyrene. The primary benefit of stereolithography molds is rapid turnaround of parts in specified materials. Philips Plastics Corp., N4660 1165th St., Prescott, WI 54021.

Design and prototyping

A firm provides industrial design and rapid prototyping services to medical OEMs, including CAD, computer rendering, finite element analysis, stereolithography, and laminated object manufacturing. Also available is a model shop. Parts can be made in both rigid and flexible urethane, metals, and various other materials. A recent project involved the prototyping of an esophageal balloon dilator produced using CAD and stereolithography. Axiom, 4912 Wallace Neel Rd., Charlotte, NC 28208.

Multiple prototype copies

Multiple copies of limited-production-run prototype parts are available in as little as a week. A proprietary reaction injection molding (RIM) process permits the production of parts at a rate 8—10 times faster than that of urethane casting techniques. The material used, which exhibits properties similar to those of ABS plastic, is stronger and more temperature resistant than standard urethane. As many as 40 parts can be produced per day on a single-cavity mold, and multiple-cavity or multiple molds can produce as many as 650 parts per week. The full-service product design and prototyping firm also offers CAD, fabricating, machining, sculpting, and injection mold tooling. Sonos Product Development, 17862 Metzler Ln., Huntington Beach, CA 92647.

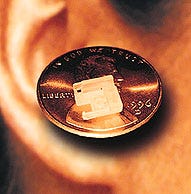

Plastic prototype parts

A company's complete stereolithography apparatus system includes an ultraviolet laser, a scanner, photopolymer, a vat, an elevator, and a controlling computer. The company uses an Aries Technology "concept station" to convert a customer's input into a computerized model. The solid model is input into the SLA, and the part is built by successively curing cross sections of photopolymer on top of one another to form a 3-D part. The company uses stereolithography to make model or prototype plastic parts, soft tooling for blow molding, and patterns for metal castings. The technology directly addresses the problems of time and expense in traditional model building. Laser Prototypes Inc., 3155 Rte. 10, Denville, NJ 07834.

Contract stereolithography

A firm manufactures prototype and conceptual models using stereolithography. Typically produced within one week, the prototypes can be used to evaluate design feasibility, verify manufacturability, perform functional tests, and reduce or eliminate engineering changes in the production phase. Prototypes produced can be as large as 20 x 20 x 24 in.; larger prototypes are available on a contract basis. Typical tolerances are ±0.005 in. for parts of less than 5 in. and ±0.0015 in./in. for parts greater than 5 in. Also available are cast polyurethane parts and silicone rubber molds for limited production quantities. Protogenic Inc., 1490 W. 121 Ave., Ste. 101, Westminster, CO 80234.

Design and development

A full-service product design and development company supports many levels of the medical device community.In-house capabilities includea full complement of industrial design, mechanical and electronic engineering, prototyping, regulatory support, tooling, and production. Development phases range from initial product specification and design conceptualization to engineering, stress analysis, prototype fabrication, bills of materials, and production tooling and manufacturing.I.N. Inc., 4392 Corporate Ctr., Los Alamitos, CA 90720.

Product development and prototyping

Twenty full-time employees, including machinists, designers, engineers, and model makers, give a company the ability to do virtually all development, design, and prototyping on its premises. The company is fully CAD integrated, its capabilities including solids modeling, photorealistic rendering, electronic schematic capture/layout, and CNC machining. It also specializesin custom product design and development. Services include industrial design, mechanical engineering, electronicdesign, software engineering, CAD/CAM/NC functional prototyping, and 3-D computer rendering. Omnica Corp., 15560-D Rockfield Blvd., Irvine, CA 92618.

Rapid product development

Providing a complete range of product development services,a company places special emphasis on significantly reducing time to market. CAD capabilities include mold-flow analysis, geometric analysis, and tolerance checking.Among the prototype production techniques usedare selective laser sintering, stereolithography, fused deposition modeling, urethane molding, and CNC machining. Recently added to the firm's array of rapid prototyping equipment is the Cubital Solider 5600 system, which quickly transforms computerized design files into 3-D models using the solid-ground curing process. Compression Inc., 7752 Moller Rd., Indianapolis, IN 46268.

Rapid functional prototypes

Advanced methods for producing rapid functional prototypes (plastic and cast metal), rapid stereolithography (SLA) models, and rapid tooling have been developed. The company specializes in prototyping complex injection-molded designs using an automated molding technology called vacuum cast molding (VCM). Some advantages of VCM over conventional RTV molding include thin-walled complex geometries filled without air voids, resins more closely resembling engineered plastics, part repeatability and consistency, and higher production rates. SLA models are handcrafted to meet dimensional and aesthetic specifications. SICAM Corp., One Harvard Way, Ste. 1, Somerville, NJ 08876.

Stereolithography

Stereolithography services are offered by a company that can produce prototypes in as little as 24 hours. Stereolithography can be used for small-run items and RTV molding. It can also be used for casting, sand casting, and die casting, and is ahands-on way for companies to further product development. The company's other services include short-run injection molding, mold inserts, and sheet-metal-forming prototypes. Vista Technologies LLC, 4457 White Bear Pky., Ste. D, White Bear Lake, MN 55110.

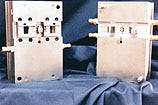

Rapid tooling manufacturer

A company uses the latest in CAD/CAM technology to make production-level tooling in two to six weeks. This allows clients to build a tool in a prototype time frame and then make a timely transition to production. Not only does the tooling's high quality and the dramatic reduction in lead time satisfy start-up requirements, but in many cases it may end up being the only set of plastic- injection-mold tooling built. The company uses Pro/Engineer and SDRC software to interface with customers. All tooling is built directly from solid-model data. Molds are usually constructed of P-20 steel and guaranteed for 100,000 pieces. There are no restrictions on tolerances or the type of geometries that can be built. Global Tool & Engineering Inc., 2009 McKenzie Dr., Ste. 116, Dallas, TX 75006.

Model-making services

Skilled in traditional handcrafting techniques aswell as 3-D CAD/CAM and rapid prototyping processes,a company produces models for a wide variety of applications ranging from 3-D conceptual studies and medical diagnostics to sophisticated product design prototypes. Stereolithography is used to create precise physical parts directly from CAD files, shortening the modeling process from days to hours. Urethane casting using RTV molds is a rapid and inexpensive solution for short production runs of rigid or flexible parts; numerous durometers, colors, and textures can be cast to represent all surface details. Satellite Models, 950 Rengstorff Ave., Ste. C, Mountain View, CA 94043.

You May Also Like