September 15, 2010

|

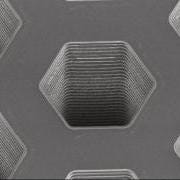

A high-magnification close-up of mPhase's nanobattery shows microand |

Power management has become so important to medical device manufacturers that engineers, scientists, and university laboratories are working at breakneck speed to develop batteries that can last for up to a quarter of a century. Contributing to the battery revolution is mPhase Technologies Inc. (Little Falls, NJ), which claims that its Smart NanoBattery is the world's first smart programmable battery technology.

"Battery technology has changed little in its fundamentals over the past 150 years," remarks Ronald Durando, CEO of mPhase. "As a result, ordinary batteries begin dissipating energy as soon as they are assembled. Chemistries are fixed inside the package, so that the user cannot interact with the contents to program functionality."

In a new approach, mPhase's superhydrophobic porous silicon membrane technology consists of a proprietary honeycomb membrane that keeps the electrolyte physically separated from the electrodes until the battery is activated. This feature prevents chemical reactions from occurring that cause the battery to provide power, Durando explains. Prior to activation, the battery remains in a quiescent state with no self-discharge, power drain, or leakage.

"Conventional batteries lose capacity while they are not in use, or even before they are used for the first time," Durando comments. "The Smart NanoBattery is built so that it is inactive and remains that way indefinitely until it is turned on."

When needed, however, it can be activated on command by means of electrowetting, the physical phenomenon by which a voltage is used to change the wetting properties of a liquid-solid interface. In the Smart NanoBattery, this process selectively allows the surface properties of the porous silicon membrane to shift instantly from a superhydrophobic to a hydrophilic state. "In other words, electrowetting acts as the triggering mechanism," Durando says. "Since self-discharge does not occur before activation, the battery has a theoretically infinite shelf life." A 'smart battery' based on chemistry that typically lasts ten years could have three groups of sequentially arrayed trigger cells, offering a combined uninterrupted service lifetime of 25 years.

In addition to relying on electrowetting, the Smart NanoBattery capitalizes on MEMS technology and microfluidics. MEMS manufacturing techniques enable mPhase to control the machining of the silicon-based materials, while microfluidics controls the flow of liquid electrolyte through the battery's porous membrane and also enables filtration and separation of the liquid. While the liquid electrolyte is initially separated from the solid electrodes, microfluidic technology enables it to move through the membrane's pores to contact the electrodes when the battery is activated.

Users can also activate the battery via an electronic trigger, making it potentially suitable for remote or hard-to-access devices, Durando says. Thus, advanced versions of the design could have preprogrammed algorithms associated with the system's supplemental circuit logic that activate the battery's cells in a controlled manner. As a result, tailored power could be supplied to stand-alone devices or in a network of distributed sensors.

While a Smart NanoBattery prototype is being developed under a work-program grant sponsored by the U.S. Army, Durando says that mPhase has its sights on the medical device industry. "The battery will be suitable for external and implantable medical devices," he adds. "These can include devices such as glucose monitors and drug-release devices."

You May Also Like