Simply the Best

As the end of another year draws near, MPMN continues its tradition of honoring some of the most buzz-worthy products and services featured in our publication in the past year. Determined by the most-popular pages in the digital edition of MPMN, the 2009 Top Products and Services of the Year begins below and continues throughout the issue.

November 16, 2009

Originally Published MPMN November/December 2009

TOP PRODUCTS & SERVICES

Simply the Best

As the end of another year draws near, MPMN continues its tradition of honoring some of the most buzz-worthy products and services featured in our publication in the past year. Determined by the most-popular pages in the digital edition of MPMN, the 2009 Top Products and Services of the Year begins below and continues throughout the issue.

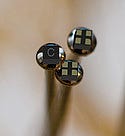

Magnetic Sensor

|

A giant magnetoresistive (GMR) magnetic sensor is designed for use in battery-powered implantable devices such as pacemakers, ICDs, neurostimulators, and drug pumps. Packaged in a four-pin 1.1 × 1.1 × 0.45-mm ultra leadframe land-grid-array leadless package, the BD020 is suitable for wire-bonding assembly. The integrated circuit consists of a GMR sensor element, CMOS signal processing circuitry to convert the analog sensor element output into a digital output, and oscillator and timing circuitry for power-management duty cycling. Configured as a magnetic switch, the sensor produces an output that turns on when a magnetic field is applied and turns off when the field is removed. In addition, the sensors have an integrated latch ensuring that the output is available continuously. The minimum magnetic operate point is 10 Oe. The applied magnetic field can be of either polarity, and the magnetic operate point is stable over supply voltage and temperature. Smaller than reed sensors, these sensors can also provide more magnetic sensitivity and more-precise operate points.

NVE Corp., Eden Prairie, MN

www.nve.com

Electroactive Polymers

|

As a result of acquiring the patents and technology belonging to a Swedish advanced materials business, a company specializing in delivery devices now offers electroactive polymers (EAPs) for use in medical applications. The Micromuscle EAP is designed to swell and contract in response to the application of a small electrical stimulus, typically in the range of 1 to 2 V. Integrated into devices in the form of a coating or a small component, the engineered biomaterial enables controlled movement to enhance the functionality of such products as guidewires, catheters, balloons, and stents. Device bending, steering, grabbing, releasing, pushing, and pulling are made possible through the use of an EAP. The material can also be employed in drug-delivery systems for controlled release of therapeutic agents.

Ceradyne Inc., Marlborough, MA

www.creganna.com

Thermoplastic Medical Extrusion

|

A service provider offers precision thermoplastic medical extrusions that are produced in a pyrogen-controlled Class 100,000 cleanroom. The ISO 9001:2000- and ISO 14001-certified company specializes in single- and multilumen tubing, thermobonded paratubing, coextrusions, and custom profiles. It also offers secondary operations and subassembly services. Specializing in medical-grade custom flexible and rigid tubing, the vendor uses USP Class VI materials, including PVC, non-DEHP, PE, PP, PU, PC, HIS, radiopaque materials, and PVC alternatives. Additional offerings include statistical process control documentation, on-line measurement, and in-house wire EDM CAD/CAM services.

Pexco, formerly Filtrona Extrusion, Alpharetta, GA

www.pexco.com

Antimicrobial Additive

|

Offered as a powdered additive, an antimicrobial can protect plastic and textile products more effectively than conventional silver-based additives, according to its supplier. Unlike competing products, the antimicrobial additive forms a permanent covalent bond with the base of the polymer, which prevents the antimicrobial from leaching, washing away, or rubbing off. In addition, the additive kills microorganisms by rupturing their cell walls, thereby eliminating the potential for adaptive or resistant microorganisms. Compliant with ISO 10993-1 and USP biocompatibility standards, the product does not contain arsenic, heavy metals, polychlorinated phenols, or volatile organic compounds.

Biosafe Inc., Pittsburgh

www.biosafe.com

Swaging Equipment

|

Allowing for continuous, automated batch processing, a company's marker band swaging equipment is suited for the high-volume manufacture of percutaneous transluminal coronary angioplasty (PTCA) products. The SW575S automatically positions and swages marker bands with tight manufacturing tolerances, which can reduce postprocessing inspection time, according to its manufacturer. Precise positioning of marker bands is performed by the machine's laser through-beam sensor and servo actuator systems, while a pick-and-place head delivers product from an autoload tray capable of holding up to 100 PTCA parts. Rejected product is automatically set aside in a separate tray by the machine. The equipment also uses the company's flexure die plate to prevent unwanted particulate and to reduce noise in the cleanroom.

Machine Solutions Inc., Flagstaff, AZ

www.machinesolutions.org

Hydrophilic Porous PSAs

A hydrophilic porous pressure-sensitive adhesive (PSA) can increase medical device functionality by rapidly transmitting fluids or gases while bonding filters and membranes. Used in such products as in vitro diagnostic devices, ARcare 92205 is suitable for coupling multiple layers of membranes or filters in lateral- and vertical-flow devices to increase reaction speed and accuracy. The adhesive transfer film's pores are uniformly distributed open cells that create a low-density, highly permeable structure. It is available in rolled-transfer or coated film formats on a range of substrates. Because it can be customized for specific applications, the film can also be used to facilitate uniform gas exchange through porous seals in microplates or ventilate seals in microfluidic devices. It can also enable the design of hybrid systems that combine ease-of-use of lateral-flow devices with the speed and sensitivity of vertical-flow devices.

Adhesives Research, Glen Rock, PA

www.adhesivesresearch.com

Piezoresistive Pressure Sensor

Suitable for use in high-volume, disposable medical devices, a piezoresistive pressure sensor complies with the AAMI BP22 specification for blood pressure monitoring. The gauge-type sensor is used in blood pressure measurement devices, kidney dialysis machines, infusion pumps, and a variety of medical instruments. It has an operating range of -30 to 300 mmHg; measures air, gases, and liquids; and can be die-packaged with or without gel. At 22°C, the sensor offers input excitation of 1 to 10 V dc, exhibits a dielectric breakdown of 10,000 V dc, has a risk current of 2 µA, and provides input impedance of greater than 200 ? and output impedance of 285 to 315 ?. The sensor operates in temperatures ranging from 15° to 40°C at humidity levels ranging from 10 to 90%.

Merit Sensor Systems, South Jordan, UT

www.merit-sensor.com

Ceramic Components

Specializing in advanced ceramics, a company produces a variety of biocompatible components that includes hermetic feedthroughs for such medical devices as pacemakers, defibrillators, cochlear implants, and neurostimulators. The supplier also has a core competency in ceramic-to-metal brazing technologies, which it applies to the manufacture of x-ray tube insulators for diagnostic imaging applications. Additional areas of expertise include hip-joint replacements and bioceramics. High-purity materials such as alumina, zirconia, and titanate are employed. All of the company's ceramic medical products are fully traceable and manufactured in an ISO 9001:2000-certified facility according to regulatory guidelines.

SCT/Euro Industries, Colorado Springs, CO

www.sct-ceramics.com

Hydrophilic Coating

A lubricious hydrophilic coating is designed to improve the maneuverability of metal guidewires used during minimally invasive neurovascular procedures. Hydrophilic coatings assist in reducing friction between a guidewire and vessel walls; however, many hydrophilic coatings do not adhere well to metals--especially in the case of coiled guidewires, according to the coating manufacturer. ComfortCoat, in contrast, adheres to metals and maintains lubricity on both coiled and uncoiled guidewires. Requiring no jacket, the coating features such properties as lubricity, durability, abrasion resistance, and biocompatibility.

DSM Biomedical, Berkeley, CA

www.dsmbiomedical.com

Blown-Ion Plasma System By bombarding a material with a high-speed discharge of ions, a blown-ion plasma surface-treatment system enables the removal of organic and inorganic contaminants from the surface of an object. Facilitating the application and adhesion of coatings, adhesives, inks, labels, and markings, the system alters the mechanical properties of a surface without changing the substrate morphology. The Dyne-A-Mite IT Elite system etches, cleans, activates, sterilizes, and functionalizes a range of difficult-to-treat conductive and nonconductive material surfaces. Typical materials treated include polyethylene, polypropylene, polyethylene terephthalate, nylon, vinyl, polystyrene, polyvinyl chloride, and other thermoformed or thermoset plastics. The modular system can be upgraded to accommodate up to four surface-treatment heads designed with quick-disconnect/connect capability.

By bombarding a material with a high-speed discharge of ions, a blown-ion plasma surface-treatment system enables the removal of organic and inorganic contaminants from the surface of an object. Facilitating the application and adhesion of coatings, adhesives, inks, labels, and markings, the system alters the mechanical properties of a surface without changing the substrate morphology. The Dyne-A-Mite IT Elite system etches, cleans, activates, sterilizes, and functionalizes a range of difficult-to-treat conductive and nonconductive material surfaces. Typical materials treated include polyethylene, polypropylene, polyethylene terephthalate, nylon, vinyl, polystyrene, polyvinyl chloride, and other thermoformed or thermoset plastics. The modular system can be upgraded to accommodate up to four surface-treatment heads designed with quick-disconnect/connect capability.

Enercon Industries Corp., Menomonee Falls, WI

www.enerconind.com

Precision Die-Cutting Services A vendor offers tight-tolerance and high-speed rotary die-cutting, multilayer lamination, narrow web slitting, flatbed die-cutting, laser cutting, and printing services. Providing subassembly support and biosensor components, the company performs converting services for a range of medical devices and wound-care applications. Equipped with a 53,000-sq-ft facility, it offers both finished products and components for device companies. Typical applications include skin-contact pressure-sensitive adhesives, filtration, venting, vibration control, sound dampening, bonding, mounting, and protection. For wound-care applications, the company specializes in the custom converting of disposable adhesive components and wound dressings, utilizing materials such as films, foils, foams, wovens, nonwovens, and hydrocolloids.

A vendor offers tight-tolerance and high-speed rotary die-cutting, multilayer lamination, narrow web slitting, flatbed die-cutting, laser cutting, and printing services. Providing subassembly support and biosensor components, the company performs converting services for a range of medical devices and wound-care applications. Equipped with a 53,000-sq-ft facility, it offers both finished products and components for device companies. Typical applications include skin-contact pressure-sensitive adhesives, filtration, venting, vibration control, sound dampening, bonding, mounting, and protection. For wound-care applications, the company specializes in the custom converting of disposable adhesive components and wound dressings, utilizing materials such as films, foils, foams, wovens, nonwovens, and hydrocolloids.

G&L Precision Die Cutting, San Jose

www.glprecision.com

Micropump A compact micropump can transfer, evacuate, or compress air or gases in portable medical instruments. Designed with a diaphragm that promotes efficiency and flow while helping to keep the pumped medium contaminant free, the NMS020 pump delivers flow rates up to 1.8 L/min, vacuum up to 15 in.Hg, and pressure up to 7.5 psig. It also features corrosion-resistant wetted parts, oil-free operation, and a range of custom material, finish, and coating options. Shock- and vibration-isolation components, a restart mechanism against vacuum and pressure, and specialized connections are among the value-added options available. Pumps can be mounted in any position.

A compact micropump can transfer, evacuate, or compress air or gases in portable medical instruments. Designed with a diaphragm that promotes efficiency and flow while helping to keep the pumped medium contaminant free, the NMS020 pump delivers flow rates up to 1.8 L/min, vacuum up to 15 in.Hg, and pressure up to 7.5 psig. It also features corrosion-resistant wetted parts, oil-free operation, and a range of custom material, finish, and coating options. Shock- and vibration-isolation components, a restart mechanism against vacuum and pressure, and specialized connections are among the value-added options available. Pumps can be mounted in any position.

KNF Neuberger Inc., Trenton, NJ

www.knf.com

Extruded Semirigid Tubing A line of extruded semirigid tubing is manufactured in an ISO 9001-registered facility using digital monitoring equipment to ensure that strict tolerances are maintained. Polyethylene and polypropylene tubing is offered with inner diameters (IDs) in almost every increment ranging from 1/16 to 13/16 in. Tubing engineered from nylon 11 is also available with IDs up to ½ in. The company's tubing is suitable for use in noncontact medical devices that require water, air, gas, or chemical delivery, such as blood analyzers. Free samples can be provided for testing and color matching.

A line of extruded semirigid tubing is manufactured in an ISO 9001-registered facility using digital monitoring equipment to ensure that strict tolerances are maintained. Polyethylene and polypropylene tubing is offered with inner diameters (IDs) in almost every increment ranging from 1/16 to 13/16 in. Tubing engineered from nylon 11 is also available with IDs up to ½ in. The company's tubing is suitable for use in noncontact medical devices that require water, air, gas, or chemical delivery, such as blood analyzers. Free samples can be provided for testing and color matching.

Ark-Plas Products Inc., Flippin, AR

www.ark-plas.com

Miniature Precision Coils On the heels of doubling the size of its Class 8 cleanroom and layer winding capacity, a company has developed a line of miniature precision coils for use in medical applications. The MicroCoil system is available with outside diameters as small as 0.012 in. and an inner diameter of 0.005 in. The coils can be wound with 39-58 AWG copper, platinum, gold, nickel, or exotic magnetic wire materials. Applications include catheter probe, cardiac navigation, implantable, magnetic generation, sensor, and proximal coils.

On the heels of doubling the size of its Class 8 cleanroom and layer winding capacity, a company has developed a line of miniature precision coils for use in medical applications. The MicroCoil system is available with outside diameters as small as 0.012 in. and an inner diameter of 0.005 in. The coils can be wound with 39-58 AWG copper, platinum, gold, nickel, or exotic magnetic wire materials. Applications include catheter probe, cardiac navigation, implantable, magnetic generation, sensor, and proximal coils.

Medical Precision Windings, a div. of Classic Coil Inc., Bristol, CT

www.medicalprecisionwindings.com

Adhesive Dispensers Providing precise adhesive dispensing for medical device manufacturing applications, a family of dispense systems features integrated inspection capabilities. The Unity IC dispense systems have a vision detection system and a feedback system for automated process control. In addition to minimizing bead width variation and maintaining material mechanical properties, the automated process control capabilities increase material cartridge life and reduce adhesive waste. The systems can handle heated and ambient-temperature high-performance adhesive materials used to assemble medical equipment. Their three-axis robot configuration is contained in a small footprint and can be incorporated into existing production lines.

Providing precise adhesive dispensing for medical device manufacturing applications, a family of dispense systems features integrated inspection capabilities. The Unity IC dispense systems have a vision detection system and a feedback system for automated process control. In addition to minimizing bead width variation and maintaining material mechanical properties, the automated process control capabilities increase material cartridge life and reduce adhesive waste. The systems can handle heated and ambient-temperature high-performance adhesive materials used to assemble medical equipment. Their three-axis robot configuration is contained in a small footprint and can be incorporated into existing production lines.

Nordson Corp., Duluth, GA

www.nordson.com

Six-Axis Robots Available with reaches ranging from 650 to 850 mm, a series of six-axis articulated robots features cycle times ranging from 0.49 to 0.59 seconds and repeatability from ±0.02 to ±0.03 mm. An increase of the robot's maximum payload capacity from 5 to 7 kg establishes the VS-series robot as having the highest payload capacity in its class, according to the manufacturer. The company also maintains that the robot's maximum allowable moment of inertia is 2.5 times greater than that of conventional robots. In order to facilitate integration, the robot has a footprint measuring 200 × 200 mm.

Available with reaches ranging from 650 to 850 mm, a series of six-axis articulated robots features cycle times ranging from 0.49 to 0.59 seconds and repeatability from ±0.02 to ±0.03 mm. An increase of the robot's maximum payload capacity from 5 to 7 kg establishes the VS-series robot as having the highest payload capacity in its class, according to the manufacturer. The company also maintains that the robot's maximum allowable moment of inertia is 2.5 times greater than that of conventional robots. In order to facilitate integration, the robot has a footprint measuring 200 × 200 mm.

Denso Robotics, Long Beach, CA

www.densorobotics.com

Connectors for Medical Applications A supplier offers circular, push-pull, modular, coaxial, miniature, and hermetically sealed connectors for a range of medical equipment, including monitors, therapeutic devices, imaging and invasive probes, electrophysiology catheters, MRIs, ultrasound systems, defibrillators, and infusion pumps. It also provides filtered connectors to protect against electromagnetic and radio-frequency interference. In addition to connector products, the company's value-added services for medical applications include kitting for various housing and contact options, color coding, solder dipping for PCB connectors, and modular connector assembly. Specializing in modifications and custom connectors, the vendor also performs special plating and custom keying services.

A supplier offers circular, push-pull, modular, coaxial, miniature, and hermetically sealed connectors for a range of medical equipment, including monitors, therapeutic devices, imaging and invasive probes, electrophysiology catheters, MRIs, ultrasound systems, defibrillators, and infusion pumps. It also provides filtered connectors to protect against electromagnetic and radio-frequency interference. In addition to connector products, the company's value-added services for medical applications include kitting for various housing and contact options, color coding, solder dipping for PCB connectors, and modular connector assembly. Specializing in modifications and custom connectors, the vendor also performs special plating and custom keying services.

BTC Electronic Components, Wake Forest, NC

www.btcelectronics.com

Lithium 9-V Battery Suitable for use in medical devices, a lithium 9-V battery features spiral-cell construction, enabling it to provide power in high-discharge-current applications. Featuring a leakproof crimp construction, the battery can operate within a range of temperatures and maintains discharge performance at low temperatures. In addition, its low self-discharge rate of less than 1% per year contributes to power retention. Environmentally friendly, the battery contains electrolytes that do not contain hazardous lithium perchlorate. According to the manufacturer, it can also last five times longer than alkaline batteries.

Suitable for use in medical devices, a lithium 9-V battery features spiral-cell construction, enabling it to provide power in high-discharge-current applications. Featuring a leakproof crimp construction, the battery can operate within a range of temperatures and maintains discharge performance at low temperatures. In addition, its low self-discharge rate of less than 1% per year contributes to power retention. Environmentally friendly, the battery contains electrolytes that do not contain hazardous lithium perchlorate. According to the manufacturer, it can also last five times longer than alkaline batteries.

Gold Peak Industries North America, San Diego

www.gpina.com

Cursor Control Device A replacement unit for a stationary mouse or trackball, a three-in-one multifunction cursor-control device incorporates an optical encoder, joystick, and push button on concentric shafts. Suited for mobile medical devices in which the use of separate joysticks, encoders, and push buttons may be impractical, the Series 60C has a 1 × 1 × 0.661-in. housing and provides the functionality of a stationary mouse or trackball in a single unit. The joystick manipulates the cursor to the left, right, up, and down; the rotary encoder facilitates sequential scrolling through menu options; and the push button performs on-screen menu selections. The encoder also features an optically coupled two-bit digital output, resulting in longer operational life than traditional position-sensing products, according to the manufacturer.

A replacement unit for a stationary mouse or trackball, a three-in-one multifunction cursor-control device incorporates an optical encoder, joystick, and push button on concentric shafts. Suited for mobile medical devices in which the use of separate joysticks, encoders, and push buttons may be impractical, the Series 60C has a 1 × 1 × 0.661-in. housing and provides the functionality of a stationary mouse or trackball in a single unit. The joystick manipulates the cursor to the left, right, up, and down; the rotary encoder facilitates sequential scrolling through menu options; and the push button performs on-screen menu selections. The encoder also features an optically coupled two-bit digital output, resulting in longer operational life than traditional position-sensing products, according to the manufacturer.

Grayhill Inc., La Grange, IL

www.grayhill.com

Dispensing Robot A series of robots is designed to improve productivity in medical device assembly processes that require repetitive deposits of adhesives, epoxies, sealants, solder pastes, and other fluids. In addition to precise dispensing capabilities, the robots feature closed-loop servo controls and drive motors. These components enable the units to dispense uniform dots, fill cavities and small containers with consistent volumes, and trace even lines over complicated part geometries. Offering a positioning accuracy of ±25 ?m, the benchtop robots employ an x-y-z positioning platform, which saves space by eliminating the need for a separate computer or external dispenser controller. The robots are available with a work envelope of 325 or 525 mm².

A series of robots is designed to improve productivity in medical device assembly processes that require repetitive deposits of adhesives, epoxies, sealants, solder pastes, and other fluids. In addition to precise dispensing capabilities, the robots feature closed-loop servo controls and drive motors. These components enable the units to dispense uniform dots, fill cavities and small containers with consistent volumes, and trace even lines over complicated part geometries. Offering a positioning accuracy of ±25 ?m, the benchtop robots employ an x-y-z positioning platform, which saves space by eliminating the need for a separate computer or external dispenser controller. The robots are available with a work envelope of 325 or 525 mm².

EFD Inc., East Providence, RI

www.efd-inc.com

Form-Fill-Seal Machine A compact form-fill-seal machine is suited for low- to medium-volume product runs. The QuickPouch Vertical forms four-sided sealed pouches from two rolls of web stock that measure up to 6 × 6 in. each. Able to handle Tyvek and clear plastic, the unit can also form pouches from foil and paper laminate. It can be integrated with automatic loading of products, including liquids, powders, and gels.

A compact form-fill-seal machine is suited for low- to medium-volume product runs. The QuickPouch Vertical forms four-sided sealed pouches from two rolls of web stock that measure up to 6 × 6 in. each. Able to handle Tyvek and clear plastic, the unit can also form pouches from foil and paper laminate. It can be integrated with automatic loading of products, including liquids, powders, and gels.

Adaptive Manufacturing Technologies, Ronkonkoma, NY

www.amtautomation.com

Overmolded Circular Connectors A provider of interconnect products has introduced a series of 0.025-in.-pitch miniature circular connectors offered with custom overmolding. Designed with a total mated length of 0.354 in. and ODs ranging from 0.122 to 0.217 in., circular Nano connectors are suited for applications for which electrical connectors must be molded into equipment housings. The connectors can be incorporated into equipment handles, casings, probes, or other such parts. To do so, connector insulators are assembled with prewired pins, sockets, or connectors that have solder lugs on the back. The connectors are spaced on 0.64-mm centerlines and are available in 6, 11, 16, and 28-position configurations.

A provider of interconnect products has introduced a series of 0.025-in.-pitch miniature circular connectors offered with custom overmolding. Designed with a total mated length of 0.354 in. and ODs ranging from 0.122 to 0.217 in., circular Nano connectors are suited for applications for which electrical connectors must be molded into equipment housings. The connectors can be incorporated into equipment handles, casings, probes, or other such parts. To do so, connector insulators are assembled with prewired pins, sockets, or connectors that have solder lugs on the back. The connectors are spaced on 0.64-mm centerlines and are available in 6, 11, 16, and 28-position configurations.

Omnetics Connector Corp., Minneapolis

www.omnetics.com

Load Cell  A structurally improved tension and compression load cell increases output symmetry and accuracy. Available with metric threads, the LCF400 is offered in 500- to 5000-lb versions. In addition, it comes with 3-mV/V, ±5-V dc, ±10-V dc, and 4-20-mA outputs, features one-piece construction, and uses heat-treated Type 17-4 stainless steel. The modified unit also offers zero-joint failure, resists high extraneous loads, and can handle off-center loading. Featuring a compact height and metal-foil strain-gauge technology, the load cell has nonlinearity of ±0.10%, bridge resistance of 700 Ohm, and deflection of 0.002 to 0.005 in. nominal. The standard load cell can be modified or customized to meet specific requirements.

A structurally improved tension and compression load cell increases output symmetry and accuracy. Available with metric threads, the LCF400 is offered in 500- to 5000-lb versions. In addition, it comes with 3-mV/V, ±5-V dc, ±10-V dc, and 4-20-mA outputs, features one-piece construction, and uses heat-treated Type 17-4 stainless steel. The modified unit also offers zero-joint failure, resists high extraneous loads, and can handle off-center loading. Featuring a compact height and metal-foil strain-gauge technology, the load cell has nonlinearity of ±0.10%, bridge resistance of 700 Ohm, and deflection of 0.002 to 0.005 in. nominal. The standard load cell can be modified or customized to meet specific requirements.

Futek Advanced Sensor Technology Inc., Irvine, CA

www.futek.com

Casting Process  A company's casting process employs graphite molds to produce high-precision parts from the zinc-aluminum alloy ZA-12. Offering an economic alternative to machining and other casting methods, the graphite casting process reduces tooling costs and expedites time to market owing to the machinability of the material, according to the vendor. The process typically yields parts with surface finishes better than 125 µin., which can eliminate the need for additional finishing operations. In-house capabilities also include design, rapid prototyping, tooling and mold production, casting, and secondary machining, if required. The process is suited for the manufacture of high-precision components for medical equipment.

A company's casting process employs graphite molds to produce high-precision parts from the zinc-aluminum alloy ZA-12. Offering an economic alternative to machining and other casting methods, the graphite casting process reduces tooling costs and expedites time to market owing to the machinability of the material, according to the vendor. The process typically yields parts with surface finishes better than 125 µin., which can eliminate the need for additional finishing operations. In-house capabilities also include design, rapid prototyping, tooling and mold production, casting, and secondary machining, if required. The process is suited for the manufacture of high-precision components for medical equipment.

Graphicast Inc., Jaffrey, NH

www.graphicast.com

Cable Connector Suited for medical applications, a vertical cable connector is offered with a two-point contact construction designed to improve vibration resistance and number of mating cycles. The space-saving connector features a low profile of 1.5 mm when mounted and a contact pitch measuring 0.4 mm, which the manufacturer claims is the smallest in the industry. In addition, vertically mated top-loaded connectors eliminate the need for additional plug insertion space, and a 1.2 × 2-mm plug dimension allows for the connector to run through a 3-mm-diam hinge hole. The product is compatible with both of the company's FPC- and wire-type plugs.

Suited for medical applications, a vertical cable connector is offered with a two-point contact construction designed to improve vibration resistance and number of mating cycles. The space-saving connector features a low profile of 1.5 mm when mounted and a contact pitch measuring 0.4 mm, which the manufacturer claims is the smallest in the industry. In addition, vertically mated top-loaded connectors eliminate the need for additional plug insertion space, and a 1.2 × 2-mm plug dimension allows for the connector to run through a 3-mm-diam hinge hole. The product is compatible with both of the company's FPC- and wire-type plugs.

Yokowo America Corp., Arlington Heights, IL

www.yokowo.com

Rubber-Based Adhesive Film Designed for medical device OEMs and converters that need to laminate various materials together during device assembly, a film features a synthetic rubber-based adhesive. TM1039 film with MP555 adhesive provides high conformability for bonding fabrics, felts, foams, films, and other materials in applications where a reinforcing carrier membrane is not required. The film bonds to uneven or irregular surfaces as well as low-energy surfaces, such as polyethylene and polypropylene. It also features a two-side, release-treated kraft liner. The biocompatible film can also be used for skin-contact applications.

Designed for medical device OEMs and converters that need to laminate various materials together during device assembly, a film features a synthetic rubber-based adhesive. TM1039 film with MP555 adhesive provides high conformability for bonding fabrics, felts, foams, films, and other materials in applications where a reinforcing carrier membrane is not required. The film bonds to uneven or irregular surfaces as well as low-energy surfaces, such as polyethylene and polypropylene. It also features a two-side, release-treated kraft liner. The biocompatible film can also be used for skin-contact applications.

MACtac Medical Products, Stow, OH

www.mactac.com

Compressor With a maximum flow of 3 cfm and maximum pressure of 30 psig, a compressor is designed to accommodate medical applications requiring a small, quiet, and lightweight pump. The 2450-series WOB-L compressor features a monolithic head that can reduce leak paths and a boltless construction that decreases noise and vibration. Optional intake locations on the side and bottom of the compressor offer increased ease of plumbing, and mounting options on the unit make installation easy. In addition to permanently lubricated bearings, stainless-steel valves, and a high-performance piston seal, the compressor features a piston and cylinder that do not require oil or lubrication. Measuring 8.3 × 4.0 × 6.4 in., it is made with lightweight aluminum components. The product's thin-wall, hard-coated aluminum cylinder is designed to provide maximum heat transfer.

With a maximum flow of 3 cfm and maximum pressure of 30 psig, a compressor is designed to accommodate medical applications requiring a small, quiet, and lightweight pump. The 2450-series WOB-L compressor features a monolithic head that can reduce leak paths and a boltless construction that decreases noise and vibration. Optional intake locations on the side and bottom of the compressor offer increased ease of plumbing, and mounting options on the unit make installation easy. In addition to permanently lubricated bearings, stainless-steel valves, and a high-performance piston seal, the compressor features a piston and cylinder that do not require oil or lubrication. Measuring 8.3 × 4.0 × 6.4 in., it is made with lightweight aluminum components. The product's thin-wall, hard-coated aluminum cylinder is designed to provide maximum heat transfer.

Thomas Products Div., Sheboygan, WI

www.gd-thomas.com

Extrusion Services A contract manufacturer offers a range of tubing services, including design, engineering, material selection, prototyping, volume manufacturing, secondary operations, and supply-chain management. Its core markets are vascular intervention, including coronary, peripheral, and neurovascular applications, as well as cardiac rhythm management, neurostimulation, endosurgery, and vascular-access products. The company manufactures catheter, lead, and device tubing fabricated from virtually any thermoplastic. Tubes are available in many configurations, including coextrusions, multilumens, and tapers. In addition, the company offers irradiated balloon tubing and polyolefin heat-shrink tubing. The supplier also complements its tubing products with value-added services, including rapid extrusion, mechanical testing, pressure testing, process validations, and inventory management.

A contract manufacturer offers a range of tubing services, including design, engineering, material selection, prototyping, volume manufacturing, secondary operations, and supply-chain management. Its core markets are vascular intervention, including coronary, peripheral, and neurovascular applications, as well as cardiac rhythm management, neurostimulation, endosurgery, and vascular-access products. The company manufactures catheter, lead, and device tubing fabricated from virtually any thermoplastic. Tubes are available in many configurations, including coextrusions, multilumens, and tapers. In addition, the company offers irradiated balloon tubing and polyolefin heat-shrink tubing. The supplier also complements its tubing products with value-added services, including rapid extrusion, mechanical testing, pressure testing, process validations, and inventory management.

ExtruMed, Placentia, CA

www.extrumed.com

Pouching and Labeling System A pouching system that opens and seals preformed pouches is offered with an integrated labeling system. Designed to improve control of the customer's printed material and ensure consistent label placement, the PM1000 can help increase productivity by automatically printing a label and applying it to the pouch in real time. The unit features a heat sealer, automatic height adjustment, a Web server, and e-mail capabilities. It can accommodate a variety of hard and soft film pouches ranging in size from 2 x 4 in. to 7.5 x 11.5 in. Offering automatic and manual modes, the machine has a throughput of 15 pouches per minute.

A pouching system that opens and seals preformed pouches is offered with an integrated labeling system. Designed to improve control of the customer's printed material and ensure consistent label placement, the PM1000 can help increase productivity by automatically printing a label and applying it to the pouch in real time. The unit features a heat sealer, automatic height adjustment, a Web server, and e-mail capabilities. It can accommodate a variety of hard and soft film pouches ranging in size from 2 x 4 in. to 7.5 x 11.5 in. Offering automatic and manual modes, the machine has a throughput of 15 pouches per minute.

Modular Packaging Technologies, San Diego

www.go-modular.com

Temperature Sensors Two Teflon-coated sensors are suitable for use in environments in which resistance to chemicals and humidity is required. The RBS-8097 RTD and the JBS-8078 thermocouple are coated with Teflon on the lead wire and measuring point to provide stable temperature measurement over long periods.The sensors can be used to measure the temperature of chemicals in medical device manufacturing operations.

Two Teflon-coated sensors are suitable for use in environments in which resistance to chemicals and humidity is required. The RBS-8097 RTD and the JBS-8078 thermocouple are coated with Teflon on the lead wire and measuring point to provide stable temperature measurement over long periods.The sensors can be used to measure the temperature of chemicals in medical device manufacturing operations.

RKC Instruments, South Bend, IN

www.rkcinst-usa.com

Power Resistors Offering circuit designers a range of package options for current-sensing applications, TO-style power resistors are suitable for use in power electronics circuits in which a higher voltage signal is needed because of a noisy environment or the circuit requires a minimum load. The compact heat-sink-mountable MP-series resistors allow high power dissipation in a compact design without creating excess heating inside the electronics assembly, according to the manufacturer. Because of their noninductive design, the components can operate in high-frequency applications and switching circuits. They offer resistance ranges as low as 0.005 Ohm at ±5% tolerance, 0.010 Ohm at ±2% tolerance, and 0.020 Ohm at ±1% tolerance. TO-126, TO- 220, TO-220 clip-mount, and TO-247 resistors are available with current and power ratings of 35 A or 25 W + 25°C case temperature, 40 A or 50 W + 25°C case temperature, 60 A or 60 W + 25°C case temperature, and 44 A or 100 W + 25°C case temperature, respectively.

Offering circuit designers a range of package options for current-sensing applications, TO-style power resistors are suitable for use in power electronics circuits in which a higher voltage signal is needed because of a noisy environment or the circuit requires a minimum load. The compact heat-sink-mountable MP-series resistors allow high power dissipation in a compact design without creating excess heating inside the electronics assembly, according to the manufacturer. Because of their noninductive design, the components can operate in high-frequency applications and switching circuits. They offer resistance ranges as low as 0.005 Ohm at ±5% tolerance, 0.010 Ohm at ±2% tolerance, and 0.020 Ohm at ±1% tolerance. TO-126, TO- 220, TO-220 clip-mount, and TO-247 resistors are available with current and power ratings of 35 A or 25 W + 25°C case temperature, 40 A or 50 W + 25°C case temperature, 60 A or 60 W + 25°C case temperature, and 44 A or 100 W + 25°C case temperature, respectively.

Caddock Electronics Inc., Riverside, CA

www.caddock.com

Extruded Balloon Tubing A vertically integrated provider of outsourced products for catheter manufacturing offers balloon and catheter design and development, extruded balloon tubing, balloon contract manufacturing, catheter contract manufacturing, and a line of balloon catheter production and testing equipment. The ISO 13485:2003- and ISO 9001:2000-certified company operates multiple Class 10,000 and Class 100,000 cleanrooms in three facilities. The manufacturer's extrusion process produces balloon tubing with consistent characteristics, delivering precise wall thickness and inner and outer dimensions while reducing gel spots. Its tubing can improve balloon performance properties such as minimal wall thickness, burst pressure, and fatigue. Offering a range of standard and custom tubing sizes, the company's tubing lots come with complete documentation, including certificates of compliance, dimensional and visual inspection reports, and tensile test reports.

A vertically integrated provider of outsourced products for catheter manufacturing offers balloon and catheter design and development, extruded balloon tubing, balloon contract manufacturing, catheter contract manufacturing, and a line of balloon catheter production and testing equipment. The ISO 13485:2003- and ISO 9001:2000-certified company operates multiple Class 10,000 and Class 100,000 cleanrooms in three facilities. The manufacturer's extrusion process produces balloon tubing with consistent characteristics, delivering precise wall thickness and inner and outer dimensions while reducing gel spots. Its tubing can improve balloon performance properties such as minimal wall thickness, burst pressure, and fatigue. Offering a range of standard and custom tubing sizes, the company's tubing lots come with complete documentation, including certificates of compliance, dimensional and visual inspection reports, and tensile test reports.

Interface Catheter Solutions, Laguna Niguel, CA

www.interfaceusa.com

Digital Dieless Cutting Services Offering digital dieless cutting services for high-precision nonmetallic parts, a contract manufacturer can cut an array of materials and shapes for medical devices, including diagnostic test strips, filters, chromatography frits, blotters, mufflers, diffusers, and wicking products. Performed in a clean-practice positive-pressure facility, the supplier's cutting services are suitable for manufacturing parts with intricate shapes, such as narrow cross sections and those with close-hole spacing. Part sizes range from less than 1 in. square to 60 × 120 in. with ±0.005-in. tolerances, depending on the material. Suited for plastics, rubbers, membranes, foams, felt, and composites, digital cutting eliminates tooling charges and permits on-the-fly modifications, according to the manufacturer.

Offering digital dieless cutting services for high-precision nonmetallic parts, a contract manufacturer can cut an array of materials and shapes for medical devices, including diagnostic test strips, filters, chromatography frits, blotters, mufflers, diffusers, and wicking products. Performed in a clean-practice positive-pressure facility, the supplier's cutting services are suitable for manufacturing parts with intricate shapes, such as narrow cross sections and those with close-hole spacing. Part sizes range from less than 1 in. square to 60 × 120 in. with ±0.005-in. tolerances, depending on the material. Suited for plastics, rubbers, membranes, foams, felt, and composites, digital cutting eliminates tooling charges and permits on-the-fly modifications, according to the manufacturer.

Interstate Specialty Products Inc., Sutton, MA

www.interstatesp.com

Pressure-Control Valve A supplier offers a proportional pressure-control valve that can control pressures ranging from vacuum to 150 psig. The QPV high-resolution pressure-control valve uses a proportional solenoid valve to avoid digital stepping while changing pressure. This technology, combined with precise pneumatic control, is designed to provide high repeatability, which can be crucial for leak-testing and liquid-dispensing applications. The valve can be employed to control air and liquid pressures in such medical applications as an inflatable cuff for limbs, a wand that vacuums fluids out of the body, or a system that dispenses a liquid sample to count cells. Available in a variety of connector options, the valve can be mounted in almost any position.

A supplier offers a proportional pressure-control valve that can control pressures ranging from vacuum to 150 psig. The QPV high-resolution pressure-control valve uses a proportional solenoid valve to avoid digital stepping while changing pressure. This technology, combined with precise pneumatic control, is designed to provide high repeatability, which can be crucial for leak-testing and liquid-dispensing applications. The valve can be employed to control air and liquid pressures in such medical applications as an inflatable cuff for limbs, a wand that vacuums fluids out of the body, or a system that dispenses a liquid sample to count cells. Available in a variety of connector options, the valve can be mounted in almost any position.

Proportion-Air, McCordsville, IN

www.proportionair.com

Packaging Robots A supplier has added two packaging robots to its line of vision-guided robotic products. The Quattro s650H parallel robot is specifically designed for high-speed packaging, manufacturing, material-handling, and assembly operations. The Cobra s850 SCARA robot is a high-performance four-axis system for packaging, loading, mechanical assembly, and other operations requiring fast, precise automation. Both robots feature high-efficiency motors that are designed to deliver more torque per amp. They also employ high-resolution encoders that provide precision and slow-speed following. Featuring servo drives, SmartServo controls, and temperature sensors, the robots serve to increase productivity, reduce integration costs, and accelerate time to market.

A supplier has added two packaging robots to its line of vision-guided robotic products. The Quattro s650H parallel robot is specifically designed for high-speed packaging, manufacturing, material-handling, and assembly operations. The Cobra s850 SCARA robot is a high-performance four-axis system for packaging, loading, mechanical assembly, and other operations requiring fast, precise automation. Both robots feature high-efficiency motors that are designed to deliver more torque per amp. They also employ high-resolution encoders that provide precision and slow-speed following. Featuring servo drives, SmartServo controls, and temperature sensors, the robots serve to increase productivity, reduce integration costs, and accelerate time to market.

Adept Technology Inc., Livermore, CA

www.adept.com

Liquid-Level Sensor A noninvasive, self-adhering liquid-level sensor has a miniature design and integral circuitry, enabling the unit to monitor liquid level by being placed on the outside of a fluid reservoir. The performance of the Sonic Eye-series sensors is not affected by the optical or dielectric properties of the fluid or container. In addition, the sensors do not pose material compatibility or contamination issues. Designed to be used in fluid-monitoring applications involving hazardous chemicals or biomedical fluids, the sensors operate with 5-24-V dc input and a choice of output options, including transistor-transistor logic, sourcing, and sinking.

A noninvasive, self-adhering liquid-level sensor has a miniature design and integral circuitry, enabling the unit to monitor liquid level by being placed on the outside of a fluid reservoir. The performance of the Sonic Eye-series sensors is not affected by the optical or dielectric properties of the fluid or container. In addition, the sensors do not pose material compatibility or contamination issues. Designed to be used in fluid-monitoring applications involving hazardous chemicals or biomedical fluids, the sensors operate with 5-24-V dc input and a choice of output options, including transistor-transistor logic, sourcing, and sinking.

Cosense Inc., Hauppage, NY

www.cosense.com

Metering Base Designed to reduce scrap associated with traditional hot-melt equipment, a dispensing unit prevents too much adhesive from being deposited by metering the adhesive at the point of application. The Vector metering base features interchangeable components and a variety of output devices. In addition to slot, spiral, and bead application methods, the unit also offers a uniform fiber deposition (UFD) spray method; all methods ensure accuracy up to ±0.5%. UFD spray technology can be used to dispense an adhesive in an omega pattern. By metering at the point of application, OEMs can save as much as 50% of the adhesive material being deposited in both machine and cross-web directions. The product's metered pumps can be changed in less than five minutes. Applicator widths range from 100 to 600 mm.

Designed to reduce scrap associated with traditional hot-melt equipment, a dispensing unit prevents too much adhesive from being deposited by metering the adhesive at the point of application. The Vector metering base features interchangeable components and a variety of output devices. In addition to slot, spiral, and bead application methods, the unit also offers a uniform fiber deposition (UFD) spray method; all methods ensure accuracy up to ±0.5%. UFD spray technology can be used to dispense an adhesive in an omega pattern. By metering at the point of application, OEMs can save as much as 50% of the adhesive material being deposited in both machine and cross-web directions. The product's metered pumps can be changed in less than five minutes. Applicator widths range from 100 to 600 mm.

ITW Dynatec, Hendersonville, TN

www.itwdynatec.com

Rapid Bonding Adhesive A supplier of adhesives and light-curing systems offers a flexible adhesive for rapid bonding applications. Adhesive 1201-M-SC can be used on a variety of rigid and flexible plastics for manufacturing such products as reservoirs, tube sets, and catheters. Compliant with RoHS directives, the product is part of a series of medical device adhesives that have been biocompatibility tested in accordance with ISO 10993 and USP Class VI standards. The adhesive cures upon exposure to light but does not contain nonreactive solvents. Curing within seconds, the product can enable faster processing for increased output and decreased assembly costs. It is compatible with gamma and EtO sterilization methods.

A supplier of adhesives and light-curing systems offers a flexible adhesive for rapid bonding applications. Adhesive 1201-M-SC can be used on a variety of rigid and flexible plastics for manufacturing such products as reservoirs, tube sets, and catheters. Compliant with RoHS directives, the product is part of a series of medical device adhesives that have been biocompatibility tested in accordance with ISO 10993 and USP Class VI standards. The adhesive cures upon exposure to light but does not contain nonreactive solvents. Curing within seconds, the product can enable faster processing for increased output and decreased assembly costs. It is compatible with gamma and EtO sterilization methods.

Dymax Corp., Torrington, CT

www.dymax.com

Custom Converting Services A contract manufacturer offers custom converting services, producing a range of disposable medical device components. The company's capabilities include island placement for transdermal and placebo patches, laminating, custom die-cutting, and printing. Providing customized private-brand production services, including manufacturing, pouching, sealing, and packaging, the FDA-registered and CGMP-compliant medical component manufacturer also provides master roll distribution of medical foams and tapes. Adhering to 21 CFR Parts 210, 211, and 820 standards, the company creates control plans and flow charts as part of total systems validation protocols, ensuring that product tolerances are met and quality checkpoints are in place.

A contract manufacturer offers custom converting services, producing a range of disposable medical device components. The company's capabilities include island placement for transdermal and placebo patches, laminating, custom die-cutting, and printing. Providing customized private-brand production services, including manufacturing, pouching, sealing, and packaging, the FDA-registered and CGMP-compliant medical component manufacturer also provides master roll distribution of medical foams and tapes. Adhering to 21 CFR Parts 210, 211, and 820 standards, the company creates control plans and flow charts as part of total systems validation protocols, ensuring that product tolerances are met and quality checkpoints are in place.

ATL Medical, Menomonee Falls, WI

www.medicaldevicesatl.com

Micropumps With a plunger seal life of 2 million cycles, a series of micropumps offers reduced downtime and high dispensing speeds for continuous and metering flow rate applications. Consisting of 10 models, the series features precision-machined inner parts that are designed to minimize wear and tear that can occur between mating parts during system operation. The pumps range in capacity from 27 ?l to 3 ml/stroke. Compact and lightweight, the pumps provide accurate and consistent flow rates and are suited for use in such equipment as clinical analyzers, including blood, urine, protein, and DNA analysis devices, as well as autosamplers. The pumps also can be customized for air-bubble removal, increased dispensing speed, volume per pulse, and port location.

With a plunger seal life of 2 million cycles, a series of micropumps offers reduced downtime and high dispensing speeds for continuous and metering flow rate applications. Consisting of 10 models, the series features precision-machined inner parts that are designed to minimize wear and tear that can occur between mating parts during system operation. The pumps range in capacity from 27 ?l to 3 ml/stroke. Compact and lightweight, the pumps provide accurate and consistent flow rates and are suited for use in such equipment as clinical analyzers, including blood, urine, protein, and DNA analysis devices, as well as autosamplers. The pumps also can be customized for air-bubble removal, increased dispensing speed, volume per pulse, and port location.

Sanwa Tsusho Company, Ltd., Tokyo

www.sanwatsusho-global.com

Drug-Delivery Device Contract Manufacturer  In addition to plastic injection molding and high-speed automated assembly, a contract manufacturer of drug-delivery devices offers packaging design and production services. Specializing in plastic passive safety systems for prefilled syringes and other medical devices, the company develops standard and custom packaging components, such as bottles and closures. The company also provides package decoration options. Material selection, testing, process control, and final qualification services are also offered.

In addition to plastic injection molding and high-speed automated assembly, a contract manufacturer of drug-delivery devices offers packaging design and production services. Specializing in plastic passive safety systems for prefilled syringes and other medical devices, the company develops standard and custom packaging components, such as bottles and closures. The company also provides package decoration options. Material selection, testing, process control, and final qualification services are also offered.

Rexam, London

www.rexam.com

Single-Use Device Manufacturing  Providing integrated extrusion services from product design to fulfillment, a vendor offers medical device engineering, manufacturing, and logistics capabilities. The ISO 13485-certified and FDA-registered company specializes in the manufacture of sterile single-use medical devices, offering tool design and manufacture, assembly, packaging, and sterilization services. In addition, it provides global supply-chain and logistics management for extruded products. The company's manufacturing facility is equipped with Class 100,000 cleanrooms.

Providing integrated extrusion services from product design to fulfillment, a vendor offers medical device engineering, manufacturing, and logistics capabilities. The ISO 13485-certified and FDA-registered company specializes in the manufacture of sterile single-use medical devices, offering tool design and manufacture, assembly, packaging, and sterilization services. In addition, it provides global supply-chain and logistics management for extruded products. The company's manufacturing facility is equipped with Class 100,000 cleanrooms.

GPS China, Galway, Ireland

www.gpschina.ie

Contract Packaging Services  Packaging design services are offered by a contract manufacturer of medical devices. In addition to individual device packaging, polybagging, and shrink-wrapping, the company provides sealing services for trays and blister packaging. Automated count-and-bag and clamshell fill-and-seal operations also are available. Packages can be designed and produced based on customer specifications and application requirements. Sterilization and distribution services also are offered.

Packaging design services are offered by a contract manufacturer of medical devices. In addition to individual device packaging, polybagging, and shrink-wrapping, the company provides sealing services for trays and blister packaging. Automated count-and-bag and clamshell fill-and-seal operations also are available. Packages can be designed and produced based on customer specifications and application requirements. Sterilization and distribution services also are offered.

HPC Medx, Hanover, PA

www.hpcmedx.com

Monitor Featuring full high-definition 1080p resolution, a medical-grade color monitor can be integrated into an OEM system for medical applications. Designed for more-natural color reproduction and improved differentiation, the 24-in. T24MSA001-MD LCD wide-screen monitor features 800:1 contrast, 500 cd/m2 brightness, and picture-in-picture capability. Connectable via DVI-I, DVI-D, composite, Y/C, or RGB video inputs, the product supports both NTSC and PAL video standards. It can also comply with various video display formats, including VGA up to WUXGA. In addition, the monitor boasts a fast response time and a 178° viewing angle.

Featuring full high-definition 1080p resolution, a medical-grade color monitor can be integrated into an OEM system for medical applications. Designed for more-natural color reproduction and improved differentiation, the 24-in. T24MSA001-MD LCD wide-screen monitor features 800:1 contrast, 500 cd/m2 brightness, and picture-in-picture capability. Connectable via DVI-I, DVI-D, composite, Y/C, or RGB video inputs, the product supports both NTSC and PAL video standards. It can also comply with various video display formats, including VGA up to WUXGA. In addition, the monitor boasts a fast response time and a 178° viewing angle.

Toshiba Teli Corp., Irvine, CA

www.toshiba-teli.com

Insert Molding Machine An all-electric 8-tn molding machine has been engineered specifically for insert molding liquid silicone rubber (LSR) parts for medical applications. The Micro-Molder comes equipped with a vertical clamp, a two-station rotary table, and a vertical injection unit. Customers can choose from three injection units capable of delivering shot sizes ranging from 3 to 20 cm³. Injection units are easily removable for cleaning or material changes, and spare units are offered by the company. In addition to a touch screen, the molder also features a control system with process monitoring displays, alarm displays, and recipes for multiple molds.

An all-electric 8-tn molding machine has been engineered specifically for insert molding liquid silicone rubber (LSR) parts for medical applications. The Micro-Molder comes equipped with a vertical clamp, a two-station rotary table, and a vertical injection unit. Customers can choose from three injection units capable of delivering shot sizes ranging from 3 to 20 cm³. Injection units are easily removable for cleaning or material changes, and spare units are offered by the company. In addition to a touch screen, the molder also features a control system with process monitoring displays, alarm displays, and recipes for multiple molds.

LMG, a div. of Trinks Inc., De Pere, WI

www.lmgpresses.com

Rotary Valves Building on a previous series of rotary microvalves, a family of rotary valves offers precise and repeatable shot sizes, low maintenance, and quick and easy installation. The TS7000 interchangeable-material-path rotary valves are designed to eliminate dead fluid volume and feature a field-replaceable feed screw and cartridge assembly. Capable of repeatable dispensing of medium- and high-viscosity fluids and pastes, the valves are suited for such applications as small-dot dispensing of surface-mount adhesives, cavity filling, and glob-top dispensing. Made of precision hardened steel, the valves are available in three feed-screw auger sizes: 16 and 8 pitch and high-output 8 pitch. An encoder motor is available for applications that require closed-loop motor control with encoder feedback.

Building on a previous series of rotary microvalves, a family of rotary valves offers precise and repeatable shot sizes, low maintenance, and quick and easy installation. The TS7000 interchangeable-material-path rotary valves are designed to eliminate dead fluid volume and feature a field-replaceable feed screw and cartridge assembly. Capable of repeatable dispensing of medium- and high-viscosity fluids and pastes, the valves are suited for such applications as small-dot dispensing of surface-mount adhesives, cavity filling, and glob-top dispensing. Made of precision hardened steel, the valves are available in three feed-screw auger sizes: 16 and 8 pitch and high-output 8 pitch. An encoder motor is available for applications that require closed-loop motor control with encoder feedback.

Techcon Systems, Garden Grove, CA

www.techconsystems.com

Medical-Grade Instant Adhesives USP Class VI adhesives offer one-part structural strength formulation that is designed to improve production and end use. Rite-Lok medical-grade instant adhesives can be used to assemble such devices as hearing aids, ventilators, syringes, and stethoscopes. Curing in less than 30 seconds, the adhesives bond plastics and rubbers, including PVC, ABS, EPDM, nylon, and composites of these materials. Having been tested for resistance to flexing, impact, humidity, and other performance characteristics, the adhesives are formulated to compensate for differential coefficients of thermal contraction and expansion. They are offered in a range of viscosities and volumes.

USP Class VI adhesives offer one-part structural strength formulation that is designed to improve production and end use. Rite-Lok medical-grade instant adhesives can be used to assemble such devices as hearing aids, ventilators, syringes, and stethoscopes. Curing in less than 30 seconds, the adhesives bond plastics and rubbers, including PVC, ABS, EPDM, nylon, and composites of these materials. Having been tested for resistance to flexing, impact, humidity, and other performance characteristics, the adhesives are formulated to compensate for differential coefficients of thermal contraction and expansion. They are offered in a range of viscosities and volumes.

3M Industrial Adhesives & Tapes Div., St. Paul, MN

www.3m.com

Air-Pressure Sensors High-accuracy pressure sensors are suitable for air-pressure measurements in oxygen concentrators, respirators, and ventilators. With a maximum weight of 1.3 g and dimensions of 21.29 × 16.71 mm, P6060 sensors contain a piezoresistive sense element in a surface-mount package. Using a 5-V input, the sensors provide a 0.5- to 4.5-V dc linear analog amplified output proportional to pressure. Users can specify digital outputs that conform to their SPI protocols. Internal temperature compensation achieved using an application-specific integrated circuit ensures an accurate ±1% of span total error band over a temperature range of 0° to 60°C. Available pressure ranges include 13 in.H2O and 0-1 through 0-75 psia, psig, and psid. The electromagnetic interference/radio-frequency interference- and electrostatic discharge-protected sensors do not experience mounting position effects and provide a fast response. They can be configured to accommodate custom pressure ranges and are available with various port connections for specific application requirements.

High-accuracy pressure sensors are suitable for air-pressure measurements in oxygen concentrators, respirators, and ventilators. With a maximum weight of 1.3 g and dimensions of 21.29 × 16.71 mm, P6060 sensors contain a piezoresistive sense element in a surface-mount package. Using a 5-V input, the sensors provide a 0.5- to 4.5-V dc linear analog amplified output proportional to pressure. Users can specify digital outputs that conform to their SPI protocols. Internal temperature compensation achieved using an application-specific integrated circuit ensures an accurate ±1% of span total error band over a temperature range of 0° to 60°C. Available pressure ranges include 13 in.H2O and 0-1 through 0-75 psia, psig, and psid. The electromagnetic interference/radio-frequency interference- and electrostatic discharge-protected sensors do not experience mounting position effects and provide a fast response. They can be configured to accommodate custom pressure ranges and are available with various port connections for specific application requirements.

Kavlico Corp., Moorpark, CA

www.kavlico.com

Custom Rotary Converting Specializing in custom rotary converting, a contract manufacturer fabricates medical device components, including intricate adhesive-based gaskets for bonding plastic molded parts and adhesive-coated rubber for sealing human blood in diagnostic devices. Offering R&D and QA/QC services, the company performs a range of manufacturing operations, including tight-tolerance rotary laminating and die-cutting, multicolor printing of packaging and label materials, heat sealing, and laminating. In addition to adhesive-based products, the supplier works with an array of nontraditional materials, such as thin elastic films, foams, and foils.

Specializing in custom rotary converting, a contract manufacturer fabricates medical device components, including intricate adhesive-based gaskets for bonding plastic molded parts and adhesive-coated rubber for sealing human blood in diagnostic devices. Offering R&D and QA/QC services, the company performs a range of manufacturing operations, including tight-tolerance rotary laminating and die-cutting, multicolor printing of packaging and label materials, heat sealing, and laminating. In addition to adhesive-based products, the supplier works with an array of nontraditional materials, such as thin elastic films, foams, and foils.

The LINC Group, Ottawa, ON, Canada

www.linc-group.com

Loading and Unloading System Featuring a Fanuc robot and end-of-arm tooling (EOAT), a system is designed to facilitate high-speed machine loading and unloading of medical devices, diagnostic test kits, and pharmaceuticals in a packaging line. The TaskMate system allows manufacturers to keep packaging lines running efficiently while reducing scrap, rework, and repetitive motion for personnel. It can also be integrated with most other packaging equipment, such as cartoners and wrappers. Offering custom vacuum- or gripper-style EOAT for product handling, the system can be programmed to handle multiple SKUs on the same packaging line. The number of Fanuc robots integrated with the system can be specified depending on the payload and reach requirements of an application.

Featuring a Fanuc robot and end-of-arm tooling (EOAT), a system is designed to facilitate high-speed machine loading and unloading of medical devices, diagnostic test kits, and pharmaceuticals in a packaging line. The TaskMate system allows manufacturers to keep packaging lines running efficiently while reducing scrap, rework, and repetitive motion for personnel. It can also be integrated with most other packaging equipment, such as cartoners and wrappers. Offering custom vacuum- or gripper-style EOAT for product handling, the system can be programmed to handle multiple SKUs on the same packaging line. The number of Fanuc robots integrated with the system can be specified depending on the payload and reach requirements of an application.

ESS Technologies Inc., Blacksburg, VA

www.esstechnologies.com

Syringe Pump Valves A manufacturer of fluid-handling products offers a line of valves for use with its RoHS-compliant syringe pump. Available in a variety of materials and configurations, the valves enable the C3000 syringe pump to be used in a variety of applications. Four styles of the ¼-28 thread port valves are offered. The 120º three-port Y-style valve is available with a plug made of UHMWPE and a body of either PEEK or PCTFE. The three other 90º valves include the three-port T-style valve and four-port Distribution valve with PEEK bodies and UHMWPE plugs, and a four-port valve with a PCTFE body and UHMWPE plug. The positive-displacement syringe pump module also uses standard communication protocols and mounting configurations to eliminate costly and time-consuming redevelopment.

A manufacturer of fluid-handling products offers a line of valves for use with its RoHS-compliant syringe pump. Available in a variety of materials and configurations, the valves enable the C3000 syringe pump to be used in a variety of applications. Four styles of the ¼-28 thread port valves are offered. The 120º three-port Y-style valve is available with a plug made of UHMWPE and a body of either PEEK or PCTFE. The three other 90º valves include the three-port T-style valve and four-port Distribution valve with PEEK bodies and UHMWPE plugs, and a four-port valve with a PCTFE body and UHMWPE plug. The positive-displacement syringe pump module also uses standard communication protocols and mounting configurations to eliminate costly and time-consuming redevelopment.

TriContinent Scientific Inc., Grass Valley, CA

www.tricontinent.com

Digital Pressure Sensors Digital pressure sensors perform precise digital signal conditioning, achieving good total accuracies. The HDI series offers absolute, differential, and gauge pressure measurements in various ranges from 10 mbar to 10 bar. The sensors perform unidirectional, bidirectional, or barometric calibrations and are intended for use with air and noncorrosive gases. Optional 3-V supply-voltage versions and special low-power devices make the series suitable for battery-powered applications. Miniature surface-mount-technology housings allow for space-saving PCB mounting and OEM design flexibility. An internal application-specific integrated circuit compensates for sensor offset, temperature effects, and nonlinearity, enabling a total error band better than ±0.5% frequency selective surface. The pressure sensors provide digital interfaces using the I²C bus protocol and analog 0.5-4.5-V output signals.

Digital pressure sensors perform precise digital signal conditioning, achieving good total accuracies. The HDI series offers absolute, differential, and gauge pressure measurements in various ranges from 10 mbar to 10 bar. The sensors perform unidirectional, bidirectional, or barometric calibrations and are intended for use with air and noncorrosive gases. Optional 3-V supply-voltage versions and special low-power devices make the series suitable for battery-powered applications. Miniature surface-mount-technology housings allow for space-saving PCB mounting and OEM design flexibility. An internal application-specific integrated circuit compensates for sensor offset, temperature effects, and nonlinearity, enabling a total error band better than ±0.5% frequency selective surface. The pressure sensors provide digital interfaces using the I²C bus protocol and analog 0.5-4.5-V output signals.

Sensortechnics, Walpole, MA

www.sensortechnics.com

Disposables Manufacturing A contract manufacturer specializes in extrusion molding of components for sterile disposable medical devices such as infusion sets, easy-to-fill disposable elastomeric infusion pumps, and accessories used for antibiotics, chemotherapy, and pain management. The company's infusion kits are latex- and DEHP-free, CE marked, and manufactured in compliance with QSR and ISO 13485:2003 standards. Its pumps are available in soft- and hard-case versions with fill volumes ranging from 50 to 500 ml, infusion rates from 1 to 500 ml/hr, and accuracies to ±10%. In addition to manufacturing services performed in FDA-registered facilities, the supplier offers a range of extrusion consulting services, including quality and regulatory expertise, process validation, and project management. It also assembles and packages extruded products.

A contract manufacturer specializes in extrusion molding of components for sterile disposable medical devices such as infusion sets, easy-to-fill disposable elastomeric infusion pumps, and accessories used for antibiotics, chemotherapy, and pain management. The company's infusion kits are latex- and DEHP-free, CE marked, and manufactured in compliance with QSR and ISO 13485:2003 standards. Its pumps are available in soft- and hard-case versions with fill volumes ranging from 50 to 500 ml, infusion rates from 1 to 500 ml/hr, and accuracies to ±10%. In addition to manufacturing services performed in FDA-registered facilities, the supplier offers a range of extrusion consulting services, including quality and regulatory expertise, process validation, and project management. It also assembles and packages extruded products.

First Medical Source, Laguna Niguel, CA

www.firstmedicalsource.com

Fiber-Optic Pressure Sensor Based on miniature optomechanical systems (MOMS) technology, a fiber-optic pressure sensor exhibits better thermal performance and stability than previous-generation models, according to its manufacturer. Demonstrating better thermal performance and greater stability than previous sensor generations, the FOP-M260 uses white-light Fabry-Perot interferometry technology, ensuring accurate and reliable measurements under all field conditions. With a diameter of 260 µm, the sensor is smaller than a 1 French catheter and half the size of the company's FOP-MIV pressure sensor.

Based on miniature optomechanical systems (MOMS) technology, a fiber-optic pressure sensor exhibits better thermal performance and stability than previous-generation models, according to its manufacturer. Demonstrating better thermal performance and greater stability than previous sensor generations, the FOP-M260 uses white-light Fabry-Perot interferometry technology, ensuring accurate and reliable measurements under all field conditions. With a diameter of 260 µm, the sensor is smaller than a 1 French catheter and half the size of the company's FOP-MIV pressure sensor.

FISO Technologies Inc., Quebec City, QC, Canada

www.fiso.com

Miniature Ball Valves A series of miniature ball valves is designed for applications requiring pressure up to 250 psig. It includes the MBV-1010 standard shutoff valve, the MBVT-1010 three-way diverting valve, and the MBVMD-1010 three-way mixing diverting valve. Compact and lightweight, the valves offer nonrestricted flow and are available with a variety of seals. The standard shutoff valve weighs approximately 9 g; the other two valves each weigh approximately 12 g. The valve bodies are available in either Type 303 or Type 316 stainless steel. All of the valves use Type 316 ball elements. Suited for use in a variety of prototype and device designs, the valves can also be used for a range of medical equipment.

A series of miniature ball valves is designed for applications requiring pressure up to 250 psig. It includes the MBV-1010 standard shutoff valve, the MBVT-1010 three-way diverting valve, and the MBVMD-1010 three-way mixing diverting valve. Compact and lightweight, the valves offer nonrestricted flow and are available with a variety of seals. The standard shutoff valve weighs approximately 9 g; the other two valves each weigh approximately 12 g. The valve bodies are available in either Type 303 or Type 316 stainless steel. All of the valves use Type 316 ball elements. Suited for use in a variety of prototype and device designs, the valves can also be used for a range of medical equipment.

Beswick Engineering Company, Inc., Greenland, NH

www.beswick.com

Custom Converting Capabilities Providing specialty materials, engineering, and manufacturing services, a supplier makes IV-site and wound-care products as well as medical devices and disposables. Using a fully equipped Class 10,000 cleanroom, the company converts materials such as electrical-grade papers, films, coated cloths, laminates, and tapes. Its manufacturing capabilities range from die-cutting and slitting to more-complex laser and water-jet cutting to produce intricate patterns and parts. With access to a range of materials, the company custom-converts diagnostic test strips and carrier frames, composite wound-care dressings, die-cut medical-grade foam tape, and woven and nonwoven biocompatible pressure-sensitive adhesive tapes. In addition, the company provides printing services for tamper-evident and custom pressure-sensitive labels used on various medical products.