Roundtable: Medical Electronics and Power Components Get Smart, Stay Small

MPMN 25th Anniversary Coverage

November 23, 2010

|

Jim Ohneck, vice president of sales and marketing (USA) at Valtronic Technologies |

|

Mitchell Gebheim, |

|

Karthik Ramaswami, |

Several experts in medical electronics and power management were asked by MPMN to weigh in on the evolution of these fields, current trends, and what's on the horizon. Moderated by MPMN editor-in-chief Shana Leonard, the roundtable consisted of Jim Ohneck, vice president of sales and marketing (USA) at Valtronic Technologies (Solon, OH); Mitchell Gebheim, senior manager of product development at Benchmark Electronics (Angleton, TX); and Karthik Ramaswami, director of product development at EaglePicher Medical Power (Plano, TX).

MPMN: In honor of MPMN's 25th anniversary, what do you cite as the most significant breakthrough in medical electronics and power management in the past 25 years?

Ohneck: There have been lots of innovations, but I think that the introduction of semiconductor technology into medical implants, especially ASICs, was paramount in making the medical electronics industry what it is today. This really enabled implants to become feasible, to shrink in size, and to require less power consumption, which took some pressure off of batteries. This was an incredible development that really pushed the whole medical electronics area.

Gebheim: The general electronics capability has increased dramatically in the last 25 years. And whether this capability is being applied to implants or handhelds or portable devices, it's significant in terms of what we can now do in the palm of our hand. Also, speed of processing data and the size of data that can be stored has changed. The thing that I see the most potential for, however, is the whole biotechnology field and the human genome project. Being able to analyze DNA and the human genome and figuring out what the makeup is holds a lot of potential. And then being able to process that data and correlate it to diseases and how things can be cured and solved is phenomenal. I think that the steps we've taken in that area to analyze and process that data and where we can go has unbelievable potential.

Ramaswami: Significant changes we have seen relate to general miniaturization of electronics and radio-frequency (RF) telemetry/communications technology. RF communication is significant in that it allows real-time monitoring of patients. Also, the neurostimulation field in general did not exist in any viable commercial form 25 years ago. Neurostimulation opened up a continuously and rapidly increasing market, first in spinal pain management, then into other areas, such as deep-brain stimulation, epilepsy, obesity control, and many others. General miniaturization in electronics has enabled active implantable devices to become smaller and last longer, reducing the need for frequent surgical replacements.

MPMN: One of the most prevalent trends in the medical device industry is the need for increased functionality while maintaining or even reducing package size. How are suppliers to the industry accommodating this demand for miniaturization?

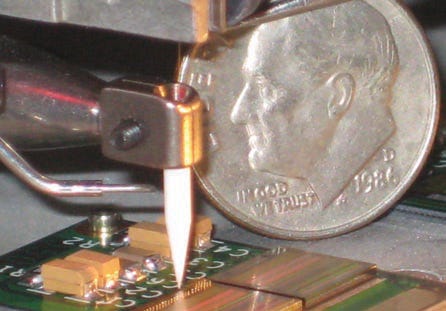

Ohneck: From our company's perspective, we've accommodated the demand through greater utilization of what we call 3-D chip-scale package designs--foldable designs--and not thinking just in two dimensions anymore, but thinking in 3-D. How can we take the electronics, put them on both sides of the board, and then roll or fold the board up to decrease the volume of the circuit? Then we're adding other technologies to that, whether it's gold ball wire bonding or flip-chip or microBGAs. These techniques certainly help us to add more functionality within the same package size or to shrink the package size. You also see PCB manufacturers on the electronics side looking at shrinking the trace widths and the distance between the traces smaller and smaller so they can make the PCBs more dense. Right now, the limitation for us is that the PCB producers can't get boards down to the trace widths that we can design to and that our equipment can fabricate to. Both the PCB and the electronics manufacturing sides are contributing to this demand with those miniaturization technologies. More people are walking in the door saying, 'I need this device in this smaller package; can you help?' and the traditional surface-mount technologies are not sufficient to do that.

Gebheim: I think Jim touched on the main items. However, there are also advancements in the packages, specifically multichip packages, package-on-package designs, and LGA packages. These types of approaches focus on the size of the technology and the size of the silicon. The main drivers in these size constraints are the consumer market, as Android phones and iPhones push for smaller packages and smaller handhelds. The challenge is that medical devices and the technology associated with them are not trivial. Consumer device manufacturers have gone down the path of coming up with the designs and processes to make products with these advanced technologies--and it's not always a specific size, but it's the 3-D size of the device because they have to make smaller and thinner devices. So, then medical device manufacturers have to take that technology and come up with a manufacturing process to get it to a viable solution for volume production. But then when you put that technology in a medical device, it's a different animal; volumes are smaller but your quality has to be higher. Learning that technology associated with consumer devices and its high-volume production and applying those processes to generate quality medical devices, that's the challenge for medical device manufacturing.

|

Miniaturization is a sweeping trend in medical electronics and power management. |

MPMN: A related issue is that of power management, especially in implantable devices. Shrinking form factors and the desire for extended implant life have placed increasing demands on EMS and battery providers. How are companies minimizing power consumption?

Ramaswami: As a battery developer and manufacturer, EaglePicher continuously researches and evaluates cutting-edge battery technology to enable the manufacture of smaller batteries with similar or higher energy and power capability to accommodate increasing functionality in a smaller package. Clearly, it is a long path from evaluation to a validated product for use in an implant. Hence, it is critical that device manufacturers work closely with critical component suppliers early in their development stage and that the battery is not an afterthought. In the medical device industry, this has generally not been an issue. We also continue to work with state-of-the-art chemistries and technology to provide the best materials that the global battery industry can provide, so long as they can deliver robust, reliable, and sustainable materials for years to come. We therefore have to critically review and evaluate new, promising technologies that do not have a long track record to manage risk to our customers.

Ohneck: Companies are trying to utilize low-power electronic circuits. They're also coming up with new techniques. For example, instead of putting a battery in a circuit, they're using a passive circuit, which is inductively coupled. So, the circuit either has a smaller battery that can be recharged inductively or it has no battery. When you bring a coil near the implant, it wakes the circuit up and processes what it needs to do and then goes back to sleep when you move the external coil away. Companies are coming up with schemes to power these implants to get around the battery issue or the size issue of the batteries; the focus is not just on battery chemistry, but on alternatives to batteries.

Gebheim: The size of the components and the size of the transistor are directly proportional to the power they need. As you make parts smaller, you need lower power. Some of the advancements in the software, operating systems, sleep modes, or the way systems power up or power down can greatly reduce power consumption. Intel parts have ridiculous numbers of power states to maximize battery life. Other technologies have different sleep modes, brownout modes, and power-consumption modes for processors or whatever the smart devices are. It's a system challenge where it's not only the parts and batteries that you're dealing with, but it's also the operating system, how the software is written, and how the system functions. It goes beyond just the parts to a bigger system approach when you're looking at power consumption.

MPMN: Many people speculate that next-generation implants won't just collect and transmit data, they'll also be able to react to the data collected. What does this mean for medical electronics design?

Ohneck: I like to call these 'Big Brother' implants because there are all sorts of things you can do to collect data on the performance of the implant now. The design of smart implants is probably going to imply a longer regulatory path because companies are going to have to demonstrate all of the conditions in which the data will be dealt with and the settings within the implant are changed. It also means that someone could react to the changing conditions and send a remote signal to the implant, which could also then change a condition. But all of those conditions will have to be tracked and justified for performance to show that they're fail-safe. This will make the time to market certainly longer and it will mean that manufacturing and production techniques employed will have to be scalable and very well tested. There will probably also have to be lengthy testing if there's RF communication, which is obviously implied here. I think this will mean a longer development path and a longer vetting process to prove all of the different conditions that will be measured--especially if you want to then react to that data. You're going to have to prove that the software is beyond reproach and that the implant can react to the data it collects and then make the right decision.

Gebheim: I started to think about this question and I got to the point where it started to scare me. The medical device OEM obviously needs to be directly tied into the patient care and treatment ideology, and how to react to the patient's needs based on the data that's gathered. So, this is sort of implying that the software engineer is going to potentially be applying medical diagnosis and treatment, which scares me a little bit. The technology is there and can easily be achieved. Smartphones are remarkable devices, for example. But you have to have the bigger picture, so it's not necessarily a black box that has no interaction; it's a whole bunch of different patients in different situations that have different processes and treatments. What if a patient has more than one condition? How do the 'smart implants' react with any other devices the patient might have? This is a problem. How does it get done? It's going to be a challenge.

|

Benchmark's MobiBAN mobile body-area network platform can communicate through cellular transmission. |

MPMN: As data is collected from implants, it could be transmitted over cellular and computer networks. How will both the medical and telecommunications industries respond to privacy issues, encryption, and robustness of the network to transmit critical data derived from an implant wirelessly?

Ohneck: This is a really fascinating topic that we've dealt with here at Valtronic firsthand. Liability is a very big issue: What happens if a dropped call resulted in the death of a patient? Cell phone companies have huge dollars at risk, and they certainly will not want to be held accountable. Today, you can program an iPhone application that can collect basic data through some sensors in the body and transmit it through the cellular network--you can measure the heart rate or the body temperature. My phone even has proximity sensors in it, so if a person falls over, you can detect that and send a signal out over the cell network. But we've also watched cell companies like AT&T block these efforts because they don't want to be accountable and responsible. I think there's going to have to be some sorting out in the industry. A lot of people want to do this. There are reasons to do this. It's even done today over hardwire networks and there's still some wireless communication going from patients' bodies to these hardwire systems. Going over the cell network is an interesting legal liability case, and it's going to take some time to sort all of that out. We've watched a couple of companies that have had these wonderful ideas fail--not because of the technology, but because they were unable to reach contractual arrangements with the cell carriers.

Gebheim: I was looking at this question slightly differently. There are a couple of different alliances like the Continua Healthcare Alliance, another consortium that's getting established to deal with medical device records security, and probably half a dozen other ones. Right now, medical device OEMs don't necessarily all get along with one another, so it would be nice if they had some sort of standards they were going by to share device records or patient information or some way of establishing communication. In a car you have onboard diagnostics, which is a standard across all industries that everyone can use. It would be nice if there was a standard in the medical industry like this; it would make life easier for everybody. Whether it can get there, though, well, I don't know if that's reasonable.

MPMN: Do you think changes to current FDA regulations could significantly affect the device industry?

Ohneck: Absolutely. There's been quite a bit of discussion on tightening the 510(k) regulations. That will certainly slow the industry down if not implemented properly and if there's not good discourse about what they're planning to change. The cursory view is that it will become more difficult to bring products to market that would normally get FDA clearance in a three-to-six-month timeframe. It will slow that process down.

Gebheim: That's my feeling as well, though with the hope that it will go the other way. As we previously discussed, using an iPhone or smartphone to do some level of data or medical analysis would be a relaxation of FDA regulations because you're using consumer devices to do some level of medical device analysis. It would be nice if things were going that way and were more relaxed in terms of legality so that efforts can be made to advance technology and achieve better patient care, but there's always the legal aspect that's going to limit what you can do.

MPMN: What does the future hold for medical electronics and power management?

Ramaswami: Battery technology improves relatively slowly compared with electronics because new materials have to be synthesized, then optimized for use in a battery. This can typically take several years to come to fruition. Higher-efficiency electronics are therefore the best near-term solution to power management.

Ohneck: What we're starting to see are more electronic packages being proposed for a host of mechanical implants. They can be used to collect data and track an implant's performance, whether it is a replacement spinal disc or a hip replacement, where you want to get electronic positioning information to see if there was any torque on the implant after it was implanted. There's been a lot of progress on the electronics side. Now, we also see people combining these areas for things that don't seem obvious yet--certainly to collect data and to potentially reduce liability if you can collect the right kind of data to show the implant was used or installed improperly. It could be the black box of medical implants.

Gebheim: I think that the universal connectivity of devices would really be something that could be achievable with today's technology. You can easily take an iPhone or Android phone and track your blood pressure, for example, and download that data to your car or home and then wirelessly transfer it to a clinic for its records. You could have a standard data storage area, and your handheld device would transmit everything from your songs and movies to your blood pressure and heart rate. It could all be stored in one central location per person and would be easily transferrable to analyze what's wrong when there's a problem. That can be done today, but the challenge is making that technology work in terms of encrypting it, combining it, and allowing it all in a single device rather than carrying around your iPad, a laptop, a glucose meter, and a navigation device.

You May Also Like