PZT Components Ensure Long Lifetime for Wireless Pacing Device

A piezoelectric electrode and transmit transducer array contribute to the energy-efficient design of the WiCS system

November 19, 2011

The subject of a high-profile recall several years ago, Medtronic's Sprint Fidelis leads for implantable cardioverter defibrillators and cardiac resynchronization therapy defibrillators proved to be vulnerable to fracture-induced failure or malfunction. In the wake of this negative publicity for cardiac pacing leads, the market opportunity for 'leadless' pacing devices is on the rise. Catering to this need, clinical-stage medical device manufacturer EBR Systems (Sunnyvale, CA) has developed a wireless cardiac stimulation (WiCS) system that it expects will be launched in Europe in late 2012 and in U.S. clinical trials in 2014.

|

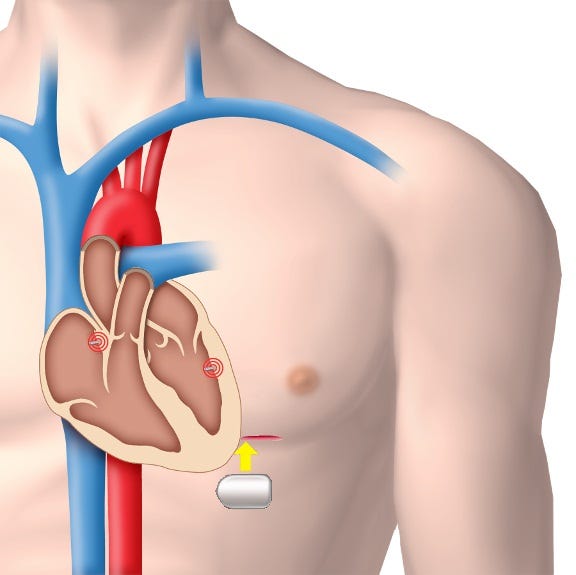

Piezoelectric components from MTC prolong battery life and contribute to the energy-efficient design of a wireless pacing system. |

Able to pace the heart through wireless transmission of energy, the WiCS system consists of a leadless electrode and a transmit transducer array (TTA), which act as an energy harvester and an ultrasonic pulse generator, respectively. While the transmitter is positioned subcutaneously in the chest, the tiny electrode is implanted inside a chamber of the heart using a catheter inserted in the artery. This system, according to EBR Systems COO Rick Riley, enables placement of the electrode in areas of the heart that are not accessible with current pacemaker leads, such as the left ventricle, for example.

"The transmitter emits mechanical energy in the form of an ultrasonic pulse, which wirelessly conducts through the body to the electrode and converts the mechanical energy into electrical energy that is used to stimulate--or pace--the heart," Riley explains. "This electrical energy stimulates the heart in the same way as is currently done with a pacemaker; however, it removes the need for a wire, or a lead, to be connected to the pacemaker."

Providing the piezoelectric materials as well as the related product development and subassembly operations for the system's two key components, Morgan Technical Ceramics (MTC; Bedford, OH) played a critical role in helping EBR Systems to maximize the energy efficiency of the WiCS device. Optimizing the energy conversion and energy utilization efficiency of the system prolongs battery life and, in turn, the life of the device, Riley says.

Achieving the necessary specifications for the lead-zirconate-titanate (PZT) electrode and the TTA proved challenging, however, states Jeff Wright, MTC Bedford's product development manager. While developing the electrode, for example, the team initially encountered difficulty in finding an epoxy system that both accommodates volume production and can cure at low temperatures.

"For the TTA, the biggest challenge has been dicing the PZT that is laminated to a titanium plate," Wright adds. "The [design] has very tight dimension specs that are required for the device to work as designed." To overcome this challenge, MTC relied on its strong technical resources and consulted with the manufacturer of the dicing saws to identify the best dicing blades for the application. Essentially, Wright notes, any design problems were resolved through close cooperation between EBR Systems' and MTC's engineering teams.

As a result of this close cooperation, the WiCS system benefits from optimized energy efficiency and a three-year battery life. "The efficiency of the system is largely dependent on many factors, but includes a large dependence on the energy conversion properties of the piezoelectric components. Both the electrical-to-mechanical conversion (transmit) and the mechanical-to-electrical conversion (receive) are important to optimize," Riley says. "MTC uniquely provides components that enhanced the energy efficiency of the system."

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)