October 1, 1999

A New Treatment Option for Women

Outsourcing was the key to developing the award-winning First Option treatment system

Sally Lane, Senior Editor

The statistics are alarming. Each year, more than 2.4 million American women suffer from menstrual disorders that compromise their health and quality of life. One such disorder, known as abnormal uterine bleeding (AUB), can lead to anemia and limit a woman's ability to work, exercise, or even leave her house.

Until recently, the only widely available and permanent treatment for AUB was hysterectomy, performed on 600,000 American women each year. Alternative options, such as drug therapy, dilation and curettage, and endometrial ablation (in which a laser, electrosurgical probe, or thermal balloon is used to remove the uterine lining) were proving more cost-effective and less invasive but were often less reliable.

A Promising Alternative

One promising option was endometrial cryoblation. In this procedure, a flexible, slender probe that generates freezing temperatures is inserted into the uterine cavity to destroy the endometrial lining. Although the treatment was promising, the accompanying technology was not. Existing devices were large, expensive, worked on high operating gas pressures, required refrigerant replenishment, and could not efficiently maintain low temperatures. These factors made the treatment cumbersome, inaccessible, and expensive.

John Dobak, MD, founder and chief technology officer at CryoGen Inc. (San Diego), was convinced this method could be improved upon. Dobak was inspired by an article in NASA Tech Briefs magazine. The article discussed the use of micro-miniature heat exchangers for achieving cryogenic temperatures in a catheter-based approach for cardiology applications. Dobak believed the same technology could be applied to endometrial cryoblation systems to create a more compact device that would effectively deliver the low temperatures needed.

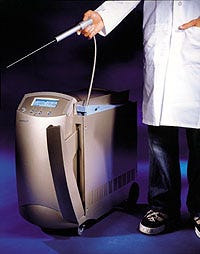

CryoGen Inc. hired Bridge Design to create the console and treatment probe for the First Option system. A hideaway compartment houses the treatment probe when it's not in use.

CryoGen Inc. hired Bridge Design to create the console and treatment probe for the First Option system. A hideaway compartment houses the treatment probe when it's not in use.

Bridge Design went through numerous iterations before creating a graphic LCD with "soft menu" control keys that allow for self-explanatory control and solve international language problems with simple reprogramming.

Bridge Design went through numerous iterations before creating a graphic LCD with "soft menu" control keys that allow for self-explanatory control and solve international language problems with simple reprogramming.

The result was the First Option Uterine Cryoblation Therapy system, which garnered two design awards this year: a Medical Design Excellence Award, presented by MPMN's publisher, Canon Communications llc (Los Angeles), and an Industrial Design Excellence Award, presented by the Industrial Designer's Society of America (Great Falls, VA).

The First Option System

The First Option system consists of:

A cryoprobe that provides a recirculating conduit to the console and generates the freezing effect.

A disposable sterile control unit that provides a patient-contact interface and contains a heater that allows a physician to warm and disengage the cryoprobe from the frozen tissue. The unit also contains a thermocouple that registers the temperature at the tip and conveys the information to the console display.

A console that receives standard electrical power input and houses the compressor system, microprocessor, and user interface.

The procedure is typically performed in 15 minutes on an outpatient basis, under either local or general anesthetic. Patients can leave after a few hours of rest and usually return to normal activities the next day. The procedure costs $2000–$3500. By contrast, hysterectomy generally costs $11,000 and requires a three- to four-day hospital stay and up to a six-week recuperation period.

First Option uses a mixed refrigerant Joule-Thomson staged system developed by Dobak. The fluid mixture and linear oil-free compressor enabled the working pressure of the device to be reduced and allowed the mixture to circulate, eliminating the need for replenishment. The closed-cycle refrigerant gas system achieves probe surface temperatures of –90° to –110°C at working pressures of up to 400 psi. This system enabled designers to create a smaller, more portable, less expensive device. Because the proprietary refrigerants are recyclable, costly gas canister replacements and a refrigerant recovery system are eliminated, says Gene Reu, vice president of engineering for CryoGen.

A Collaborative Effort

Teamwork was the key to developing First Option. To develop a reasonable prototype in a short period of time, CryoGen engaged the design and development firm Bridge Design Inc. (San Francisco).

"We pursued outsourcing activities to speed the product development effort. We had a couple of key areas of the system that had to be developed, such as the console and user interface," Reu says.

"CryoGen needed a company that could understand all of the issues involved," says Bill Evans, Bridge president. "The fact that we are an ISO 9000 company was a factor as well. They really needed someone who was a team player."

For Bridge, the main challenge in designing the First Option console was the fact that designers basically had to start from scratch. "What you tend to see are products that are variations on existing products. That's a lot easier than the effort it takes to create a new platform technology. You're pretty much starting with a blank sheet of paper," Evans says.

To create the final product, Bridge assembled a cross-functional team including core scientists, the console team, safety experts, and manufacturing, marketing, and FDA representatives. To garner feedback, Bridge went through a six-month product-definition period that involved visiting doctors' offices with chipboard prototypes mounted on wheels, loaded with weights. Bridge also took along laptop computers loaded with a Shockwave-based simulation model of the user interface.

The feedback resulted in Bridge simplifying the interface by making the verbiage clearer and making the steps involved more logical, Evans says. (View interface model.)

The goal was to create an end product that was highly portable and easy to use yet attractive to enhance marketability. "We helped them get good looks into a product with high function to ease market acceptance of the new technology," Evans says.

The final product is 30 in. tall x 15 in. wide x 28 in. deep. Previous systems were the size of a refrigerator, Evans notes. First Option consists of recyclable materials, mainly plastics and aluminum. The external panels can be easily removed for service access, enabling critical maintenance of the compressor and umbilical probe line, which have to be field replaceable. Other internal systems are modularized for ease of service. The console conceals the treatment probe and cables in a pop-up compartment when not in use, and features a foldaway handle for easy maneuvering.

First Option is currently being produced in low to medium volume (hundreds per year) with a high unit cost because of its expensive core technology. The product, which has been in clinical trials since mid-1998, recently has been released to targeted reference sites, Reu says.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like