May 1, 1998

ON MACHINING SERVICES

Machining services

Ultraprecise machining of medical and dental components, devices, implants, and instruments is offered by a company that has capabilities in prototype and short runs to full production. The company specializes in titanium, platinum, stainless steel, and other exotic metals using CNC Swiss screw machines. Other services include turning, microhole drilling, fine threading, CNC milling, slotting, fine deburring and polishing, bead blasting, and other finishing. Specialized Medical Devices Inc., P.O. Box 1704, Lancaster, PA 17608.

Plastic components

A company supplies precision-machined plastic components to the medical device industry. It can machine reusable surgical instrument handles, bone-drill motor housings, fittings, and various other plastic components. Prototype through production-quantity runs are efficiently processed in its manufacturing center. Whether the requirements are preproduction-machined prototypes or a production run of an existing design, the firm can incorporate the customer as an integral member of its manufacturing team. Materials include Radel-R, Ultem, polysulfone, Delrin, UHMWPE, nylon, ABS, and PEEK. American Industrial Plastics Inc., 724 Fentress Blvd., Daytona Beach, FL 32114.

Precision machining

A full-service contract manufacturer has 37 years of experience with the design, production, and assembly of metal, plastic, and rubber products for medical applications. Capabilities include CNC machining (four axis), CNC jig grinding, CNC wire EDM, EDM drilling, mold building, plastic injection molding, and metal stamping (long and short run).The company also designs and builds compound and progressive dies for metal stampings from miniature components to those requiring up to 75-tn presses. Die design and building of rubber and plastic molds, as well as manufacturing of plastic injection molded parts, are also available. Straton Industries Inc., 180 Surf Ave., Stratford, CT 06497.

Close-tolerance parts

An OEM supplier provides extremely close-tolerance components. Surgical parts are machined for the dental, orthopedic, pacemaker, neurological, laparoscopic, and instrumentation industries. Materials routinely used include titanium, medical grades of stainless steel, gold alloys, and many other difficult-to-machine metals and plastics. The FDA-registered company also offers 100% burr-free inspection, CNC capabilities, and prototype-to-production services. Microcision Inc., 5805 Keystone St., Philadelphia, PA 19135.

Close-tolerance parts

An FDA-registered manufacturer is dedicated to machining close-tolerance metal and plastic components for use in medical devices, implants, and diagnostic instrumentation. Capabilities include CNC milling, turning, and Swiss turning. Prototype through production quantities are accepted. Manufacturing is in compliance with ISO 9002 and GMP standards. Criterion Instrument, 5349 W. 161 St., Brook Park, OH 44142.

Tubular products

Two problems that some medical device manufacturers face are finding desired alloys including 6-4 titanium in tubular form, and accurately drilling them in lengths beyond 3 or 4 in. Using a proprietary process, a company can solve both these problems. It can drill these alloys and maintain at least a 0.25- to 0.38-mm TIR wall variation throughout a length of 400 to 500 mm. A key advantage to this process is that the company can provide this accuracy in a device with a finished OD size. No finish grinding is necessary to correct concentricity. The process enables metallurgists to provide the optimum choice of alloys to design engineers for the development of tubular devices and implants. Dearborn Precision, 80 Portland St., Fryeburg, ME 04037.

Machining and contract manufacturing

A full-service contract manufacturer has capabilities in precision laser cutting and welding, five-axis CNC, five-axis machining and grinding, and five-axis EDM. It has stamping and coining presses up to 220 tn. Forming, bending, deburring, and finishing services are provided. The company has 20 years of experience in developing surgical, dental, and medical products. DS Mfg. Inc., 2188 Knoll Dr., Ventura, CA 93003.

Machining of specialty metals

A company specializes in the machining of precious metals. Services include CNC Swiss-type screw machining, electrical discharge machining, milling and lathing, machine part coating, and laser-weld subassembly. A range of medical-grade specialty metals are available. The firm's analytical measurement capabilities ensure that products are produced on time and to specification. Johnson Matthey, Precious Metals Div., 1401 King Rd., West Chester, PA 19380.

Rapid micromachining

A company offers complete prototype micromachining and contract manufacturing services. A compact system using laser micromachining technology allows quick prototyping of medical devices. The MicroMaster microdrills, strips, and etches polymers, glass, thin metals, ceramics, and inorganic materials with tolerances from microns to millimeters. It is designed for engineers who require a flexible machine to bring products to market from design concept to final tooling. Once the process is developed, the system can often be used as the final production equipment. Resonetics Inc., 4 Bud Way, #21, Nashua, NH 03063.

Custom high-precision machining

Custom-designed components are available as prototypes or for long production runs from a company that offers precision machining with CNC and Swiss automatic screw machines. Complex components can be manufactured with diam tolerances to ±0.0002 in. in sizes ranging from 1/32 to 3/4 in. Projects have included a catheter for atherectomy and a specimen carrier for high-pressure tissue freezing. Statistical process control is performed to ensure that high-quality parts are delivered on time. Swiss Precision Inc., 908 Industrial Ave., Palo Alto, CA 94303.

Laser micromachining

A company offers a variety of precision laser micromachining services. Capabilities range from the machining of thick- and thin-film ceramic substrates to resistor trimming and dynamic integrated circuit link blowing. Additionally, permanent laser marking of packages, lids, substrates, and components is provided. Other laser services include welding, package delidding, microfine wire stripping, precision heat treating, and surface ablation. Titanium, BeO, AIN, diamond, quartz, silicon, and tungsten are some of the materials processed. Questech Services Corp., 2201 Executive Dr., Garland, TX 75041.

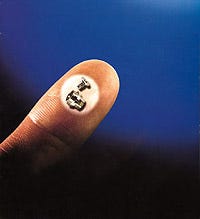

Micromachining

An ISO-certified company has a micromachining division that provides manufacturing services, specializing in the machining of miniature and micromachined ultraprecision medical device components. Critical and complex parts are machined in one operation for enhanced accuracy, repeatability, and production rates using eight-axis Swiss CNC and five-axis micromills. Micromachining work includes prototyping for preproduction and production in a variety of volumes, applications, materials, and scheduling requirements. Remmele Engineering Inc., Micro Machining Div., 17701 U.S. Hwy. 10, Big Lake, MN 55309.

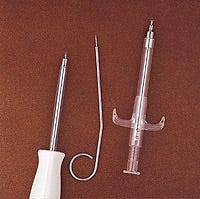

Wire-based components

A supplier of precision wire-based medical components offers continuous conical-needle grinding capabilities. The process produces mirror-finish parts with ultraprecision tips. Applications include solid conical points with straight linear tapers, and convex/concave or bullet-shaped profiles. Chamfered tubing and tapered pins can also be produced. Capabilities include diameters from 0.010 to 0.130 in. and lengths up to 5 in. in a variety of materials such as stainless steel, tungsten, and nitinol. New England Precision Grinding / Precision Wire Co., Milford, MA 01757.

You May Also Like