Medical Device & Diagnostic Industry Magazine MDDI Article Index

January 1, 2006

Medical Device & Diagnostic Industry Magazine Originally Published MDDI January 2006 Product Development Insight Manufacturers can use design for six sigma as a development tool; it can also help satisfy the QSR requirements. By Vinny Sastri

Design for six sigma (DFSS) is both a business management tool and a product development process. It uses metrics, data and statistics, team dynamics, risk management, and project management tools. Data-driven decision-making processes take products from concept to commercialization. By focusing on design and process parameters, manufacturers can create six-sigma-capable products or services that are based on customer and market needs. In addition—and perhaps more importantly—DFSS enables a company to comply with the quality system regulation (QSR) in the product development process.1

The six-phase product development process covers the entire product development cycle from idea to eventual sales (see Table I). Notice that each step should end with a risk assessment. Managing risk at each stage helps mitigate and resolve possible problems before they increase costs or present a safety risk for users. Numerous studies have illustrated that having a cross-functional team integrally involved throughout the product development life cycle leads to high success rates in launching sustainable new products.

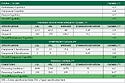

Table II provides a possible organization for how a cross-functional team can be involved in the new product development life cycle. During the process, responsibilities shift and team members need to be able take on (or give up) levels of responsibility. For example, marketing takes the lead in defining the product development strategy and identifying the applications and customers in the beginning stages of the product development cycle. They are kept informed of the process during the actual design and development of the product, but reemerge in the commercialization stages to drive the marketing initiatives of the new product. To keep the product successful in the market after launch, the marketing department is an active participant. Even though various functions assume the lead during different phases of the product development cycle, the project manager's role is to maintain continuity. The project manager is the glue that holds it all together. The Quality System Regulation The medical device QSR “governs methods used in, and the facilities and controls used for, the design, manufacture, packaging, labeling, storage, installation, and servicing of all finished devices intended for human use.”1 It ensures that medical device companies design, develop, manufacture, and distribute products that are safe and effective for the patient as well as the end-user. The regulation includes controls related to design, purchasing, production, acceptance activities, labeling and packaging, quality, and documentation. DFSS can help firms meet QSR requirements because it incorporates quantifiable metrics, controls, statistical quality control techniques, and documentation. Figure 1 details a six-stage product development process incorporating the requirements and documentation of 21 CFR 820. DFSS for QSR

Various QSR elements fit into each phase of a rigorous product development process. These phases can be broken down in a series of steps as follows: • Define the business case, customer requirements, and the intended use. • Assess the technical requirements, specifications, and various design options. • Develop and verify the product. • Validate by piloting and testing the product internally; validate with the customer or end-user. • Launch to full-scale production and commercialization. • Sustain the product; monitor and track product capability through the entire supply chain. Phase 1: Define. The definition phase is a critical step in crystallizing what is often a fuzzy front end. This involves clarifying goals to get a detailed picture of the product and determining the packaging and labeling requirements for the intended use. One of the biggest challenges for device firms is to identify an unmet need in the market and discern the critical requirements of a device for that intended use. The information is typically analyzed by marketing, with input from design and engineering. Some basic questions need to be answered for this phase: • What unmet need will the new product fulfill for the market, customer, or end-user? What are its benefits? • What is its intended use? How will the end-user use the device? What are the requirements for the intended use (e.g. safety, efficacy, performance, and user interfaces)? • How does the new product fit into the overall business strategy? Does this device make business sense for the company? The business case must also include a thorough market and competitive analysis. In six-sigma terminology, the voice of the customer is used to identify the device performance, labeling, and packaging requirements for the intended use. Lawrence Friedman gives an excellent treatise on targeting the right markets and aligning with customers in his book Go to Market Strategy.2 Additionally, a detailed analysis of human factors in both form and function to ensure ergonomic handling, aesthetics, error-free performance, and ease of use must not be ignored.3 Various methods can be used to obtain the voice of the customer and voice of the market. Methods often include interviews, focus groups, surveys, observation, and behavior modeling. Information from the voice of the customer is distilled down to quantifiable finished device performance specifications.

Quality function deployment (QFD) takes high-level customer needs and correlates those needs with the critical performance specifications of the device. The performance specifications can be linked to the device design and component specifications, and the component specifications can then provide the processing controls. Figure 2 illustrates how QFD can be used to identify critical production and processing parameters that will produce a consistent product with the desired performance capabilities. The information from this phase is documented as the design input, which is part of the design history file (DHF) for the QSR (see Figure 1). • Detailed product or device properties, specifications, and acceptance criteria (including performance needs after sterilization and biological or chemical fluid contact). • The test measurements for the acceptance criteria, and evaluation of test measurement capability. • Processes for prototyping and design evaluation. • The appropriate development path and plan. Assessment is led by marketing, design, and engineering. From the end-user requirements, the product properties that are critical to quality specifications and tolerances are quantified using QFD. Examples include working out the exact dimensions and tolerances, clarity, toughness, electrical output, aesthetics and color, and compliance needs of the product. Designing and developing the product becomes much easier once the device outputs are well defined. Design options are whittled down to one design that meets all the product requirements. Before developing the product, it is important to ensure that the test measurements used for the acceptance of the components, subassemblies, and the finished device are capable. Large variations in a measurement system would make it impossible to determine whether or not a product is within specification. Standard methods of evaluation are the gauge repeatability and reproducibility (GR&R) test and the precision to tolerance ratio (P/T) test. Both results are expressed as percentages. Preference should be given to ANSI, ASTM, ISO, or other industry-standard test methods. The outcomes of this phase include criteria for inspection, measurement, and test equipment that are part of the production and process controls required by the QSR. Product specifications, design options, and design selection (i.e., design inputs) are recorded in the DHF. The cross-functional product development team formulates a detailed design-and-development plan that is also part of the DHF. Phase 3: Develop and Verify. During the third phase, technology and engineering take the lead in developing the new product based on the selected design. After a design review, a prototype is developed. The prototype's properties and performance are evaluated, including clinical trials, with respect to customer specifications and intended use. There are various techniques to evaluate the sigma capability of the product using predictive models and information obtained from statistical techniques. Some of these are design of experiments, regression analysis, analysis of variance, and capability scorecards.

An example of a design capability scorecard is shown in Table III. Model equations are generated based on first principles, modeling, or design of experiments. The equations highlight the sensitivities of those components that influence the critical properties of the finished device. The benefit of this type of scorecard is that it identifies those components and parameters that need to be controlled during production. It also assesses the capability of the device based on the existing design. Redesign may be necessary if the prototype is not six-sigma capable by design. Information is documented for QSR compliance in the DHF and is the source for the design inputs, design outputs, design verification, and the device master record (DMR).

Phase 4: Validate. To obtain a statistically significant standard deviation for the product, manufacturers need to make a minimum of five consecutive lots on a pilot scale. Evaluation of finished-device capability is based on critical-to-quality characteristics for the intended use. A capability scorecard details the performance of the influencing components, processing conditions, and device properties. It also provides an assessment of the overall capability of the product (see Table IV). Low-capability components must be identified and their performance improved via root-cause analysis. The end-user or customer must also validate the product. Product development at this stage could take a significant amount of time, depending upon the complexity of the validation at the end-user, and any additional clinical testing that might be required. • The DMR details intended use, specifications for device outputs and raw materials, production protocol, packaging and labeling, acceptance activities (raw materials, in-process, and finished device), storage, handling, distribution, and servicing of the finished device. • The Design Transfer contains standard operating procedures, tests, and acceptance activities for the production, assembly, and distribution of the finished device. It includes the identification and disposition of nonconforming products, from incoming raw materials (purchasing controls) to finished goods. • The DHF includes all information gathered during the design stage, including design inputs, outputs, verification and validation, reviews, and changes. Phase 5: Launch. Full-scale production is led by manufacturing, and the commercialization process is led by sales and marketing. Product, process, and performance capabilities are continually evaluated for performance in production and at the end-user level. The intent of DFSS is to design the new product to be robust and consistent during production, taking into account the variability of raw materials and process manufacturing. According to the 21 CFR 820 Preamble, “you cannot inspect quality into the product. You have to build it into the design and process.”4 Ideally, production and process controls (with minimal testing and inspection) should be adopted. Statistical techniques like statistical process control (SPC), statistical quality control (SQC), and product capability scorecards are used to control and monitor the product and the process. One of the major factors in a successful product launch is the quality of the product launch itself.5 Giving insufficient resources or attention to marketing and sales often means the product will experience sluggish sales and poor market acceptance. Commercial activities should highlight the intended value of the product. End-user feedback should be monitored to ensure the product meets the intended use criteria and is safe and effective. For QSR compliance, all production, testing, distribution, installation, and servicing data are documented in the DHR through the life cycle of the product. Changes to processes and product should be captured in the change management and corrective and preventive action (CAPA) process. Phase 6: Sustain. The finished device should be monitored and tracked through the entire supply chain for a specific length of time or a predetermined number of lots to evaluate the capability of the entire process. This can be accomplished by setting up a regular audit schedule with a list of attributes to monitor. Such practices will also help prepare for FDA inspections. Product capability should be monitored over a predetermined period of time to identify any major shifts or drifts which are related to changes in the process or raw materials over time. Root causes of these shifts or drifts must be identified and corrected. Any changes must be recorded in the CAPA files. Before closing out the development project and making the product self-sustaining and operational, the development team should review the results (sales, revenue, quality, margins, product capability, development cycle time, etc.) versus the original plan. This information is used in the continuous-improvement loop of the quality system process. The DHR is the repository for all product data. Conclusion Companies should review their product development processes and assess how to bring rigor and quality regulation compliance into a single business process. Using DFSS tools and methodologies and integrating QSR within a company's new product development process can bring structure and clarity, reduce risks and time to market, and ensure regulatory compliance. Finished devices can be designed, developed, manufactured, and sold with six-sigma capability to meet end-user needs and to maintain their intended use. This leads to product consistency and reliability, and sustainable sales, revenues, and profits. Simplifying the various development processes into one integrated, manageable process enables better control and compliance. This may mean changing the way product development is conducted within a company. The challenge is to devise and implement a meaningful, sustainable process that will become second nature in conducting business and will not be perceived as additional work. References 1. Code of Federal Regulations, 21 CFR 820. 2. LA Friedman, “Targeting the Right Markets” and “Aligning with Your Customers” in Go to Market Strategy (New York: Butterworth-Heinemann, 2002). 3. ME Wiklund, “Return on Investment in Human Factors,” Medical Device & Diagnostic Industry 27, no. 8 (2005): 48–55. 4. Code of Federal Regulations, 21 CFR 820, Preamble. 5. RG Cooper, Winning at New Products, (New York: Basic Books, 2001). Vinny Sastri is the founder of Winovia (Albany, NY) and can be reached at [email protected]. Copyright ©2006 Medical Device & Diagnostic Industry |

You May Also Like