April 3, 2012

Because they are exposed to a fluidic environment, metal-based medical device implants are susceptible to corrosion. In the case of intravascular stents, for example, FDA warns that corrosion can cause or contribute to premature stent failure, generate toxic by-products, or result in adverse biological and tissue responses. Seeking to develop a new generation of coatings that could eventually be used to prevent such issues, researchers at Vanderbilt University (Nashville) are exploring the use of graphene, a corrosion-resistant material with a variety of properties that could render it suitable for implantable medical devices.

|

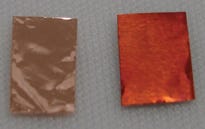

A piece of copper foil with a graphene coating has not oxidized, while a piece of foil without the coating (right), shows the effects of oxidation. |

Consisting of carbon atoms that form a single monolayer of graphite, graphene is impervious to corrosion, comments Kirill Bolotin, an assistant professor of physics at Vanderbilt. "For example, cyclic voltammetry measurements that we have performed show that it effectively suppresses metal oxidation and oxygen reduction. And electrochemical impedance spectroscopy measurements suggest that a graphene coating on top of a metal substrate remains undamaged, while the metal itself corrodes where cracks in the graphene film form." These findings confirm earlier study results from Rodney Ruoff at the University of Texas at Austin and Jiwoong Park at Cornell University.

Tafel analyses, also performed by Bolotin and his team, highlight graphene's superiority over an assortment of bare metals. Thus, while copper films coated with the material corrode seven times slower in an aerated Na2SO4 solution than bare copper, nickel coated with a multilayer of graphene film corrodes 20 times slower than bare nickel. Furthermore, nickel surfaces coated with four layers of mechanically transferred graphene corrode four times slower than the bare metal, according to the group's studies.

In addition to exhibiting corrosion-resistance, graphene is the world's thinnest material. Indeed, it is so thin that a single layer is transparent, and it is so light that an ounce of it would cover 28 football fields. But despite its thinness, graphene is completely impermeable to even the smallest molecules, such as helium. "These properties make it uniquely suitable for applications such as a coatings," Bolotin remarks.

Graphene, according to Bolotin, also features others properties that make it potentially suitable for use in corrosion-resistant coating applications. For example, it can be grown on many different types of metals, including copper, nickel, and ruthenium, and it can also be mechanically transferred onto other types of metals. In addition, because graphene is chemically inert, it is biocompatible, making it suitable for use in medical device applications.

"However, one problem that is likely to be encountered is mechanical abrasion," Bolotin cautions. "It's not clear to what extent a monolayer of graphene can withstand mechanical friction. Thus, a graphene coating would most likely be suitable for implant applications that do not involve high levels of friction."

You May Also Like