AdvaMed Releases White Paper on 510(k) Process

October 1, 2008

NEWS TRENDS

|

(click to enlarge) |

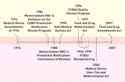

The 510(k) process has been used to clear about 90% of medical devices for U.S. marketing since its inception in 1976. Yet to many outside the medical device industry, and even to some within the industry, the process is not well understood. So in August, AdvaMed released a white paper explaining the history of the 510(k) process and how it works.

It concludes that the 510(k) process is “an appropriate and effective regulatory approach for the vast majority of medical devices” because it allows “patients to have access to essential lifesaving, life-enhancing, safe medical technology in a timely fashion.”

In the mainstream media, there is often commentary about how most medical devices do not undergo the same level of regulatory scrutiny as drugs, with the implication being that this is a bad thing. But, the report says, the 510(k) process “is of critical importance in ensuring that medical devices are neither underregulated nor overregulated.” This is not an easy thing to accomplish, considering that about 3500 products go through the 510(k) process each year.

Because the world of medical devices encompasses so many different products and technologies, it doesn't make sense to have them all evaluated the same way, the report states. Rather, appropriate scientific evaluation methods differ depending on the type of device, and the level of risk it presents.

“Were every medical device subject to the rigorous PMA process, there would be very few new and innovative medical devices entering the market and few or no improvements to marketed devices,” the report states.

The report provides a history of how the Medical Device Amendments Act of 1976 was created and what the rationale was for setting up the 510(k) process as part of that law. In particular, those who shaped the law understood that it did not make sense to hold most devices to the same evidentiary standards for safety and effectiveness as drugs. Part of the reason was that they understood that the medical device innovation process was quite a bit different from that for drugs. Devices have much shorter life cycles, and their manufacturers frequently produce new versions based on feedback from users and real-world data.

The report also debunks four myths about the 510(k) process. The first myth is that “substantial equivalence” means showing a new device is similar to one on the market before May 1976. In fact, most of today's 510(k) devices show equivalence to state-of-the-art products. And a device cannot be considered substantially equivalent to a product that has been removed from the market or found to be adulterated or misbranded.

The second myth is that the 510(k) program is just a “quick and easy way” for device makers to get their products on the market. In fact, it is not uncommon for review times to exceed 90 days, especially if the application includes significant changes in technology or in intended use. And only the simplest of devices are cleared based on a comparison of specifications. More devices are cleared based on nonclinical testing; about 8% of 510(k) clearances involve clinical data. All must have gone through the design control process, which includes risk analysis.

The third myth is that device malfunctions and patient injuries result from 510(k) devices. The reality, the report states, is that many of the products cited in those arguments were faulty because of manufacturing problems. Those problems cannot be detected in paper reviews, whether PMA or 510(k). Instead, they are detected when a firm's quality system is inspected. Nor can premarket clinical evaluation, whether PMA or 510(k), predict every problem that might occur when a device hits the market.

The fourth myth is that the 510(k) third-party review program is just a means for manufacturers to avoid FDA review. In fact, third-party reviews are no less rigorous than those done by the Office of Device Evaluation (ODE). They are performed more quickly because they are not sitting in a queue at ODE. And FDA does not have to accept the third-party reviewer's decision.

The full report can be seen at www.advamed.org.

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like