Using Laser Marking to Meet UDI Requirements

Laser marking is an effective and safe solution for marking unique device identifiers directly onto medical devices.

August 8, 2017

Laser marking is an effective and safe solution for marking unique device identifiers directly onto medical devices.

Tom Glass

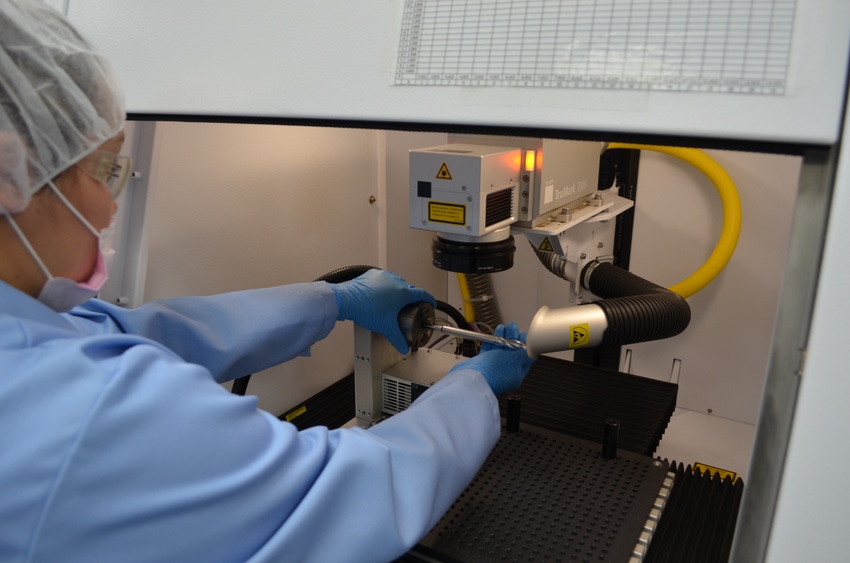

Laser marking can be used to mark medical devices with a unique device identifier. |

In 2013, FDA enacted a measure that requires most medical devices manufactured in the United States to carry a unique device identifier (UDI). This rule is intended to improve patient safety and increase accountability for manufacturers of medical devices in case of an adverse event. Laser marking is an effective and biocompatible method to keep manufacturers fully compliant with these new labeling requirements.

Why Unique Device Identifiers?

|

Laser marking can be used to apply alphanumeric codes, logos, and most common forms of barcodes directly onto metal parts. |

The vast majority of the time, medical devices and implants perform correctly, and patients experience no harmful effects. In the rare event that a malfunction or other adverse event takes place, however, the ability to pinpoint when and where the device was manufactured goes a long way toward understanding what malfunctioned and taking steps to prevent it from occurring again. It also allows FDA to hold medical device manufacturers accountable for product performance once their products are in use. A UDI is a series of letters and numbers that consists of two parts:

Device Identifier. This portion of the UDI will be the same for all devices of a specific model and identifies the device and the labeler, rather than an individual product.

Product Identifier. The second part of the UDI is a unique code meant to identify a specific product. It could be based on a lot or batch number, the date the device was manufactured, its expiration date, and/or the device's serial number. Certain types of medical parts and implants must use a code specified by law.

These identifiers are mandatory and must be registered with an FDA-accredited issuing agency to improve post-production monitoring of medical devices by FDA.

How Laser Marking Can Help Ensure UDI Compliance

UDIs are required on most medical device part labels and packages. Devices that are intended for multiple uses with reprocessing before each use also must have the UDIs directly marked on the parts. The identification must be included in a format that can be easily read by human beings, as well as a format that allows for fast computer scanning for identification. The difficulty with many medical devices is that their manufacturing is an incredibly precise process, and alterations made to comply with UDI requirements cannot negatively impact the proper functioning of the part and compromise biocompatibility.

Laser marking can meet UDI requirements because it is 100% biocompatible and does not affect the part's functioning. This process will effectively mark a wide range of product shapes and sizes, from flat two-dimensional faces to three-dimensional components and even cylinders. Laser marking is versatile in that it can accurately mark alphanumeric codes in any font, as well as logos and other graphics. The most common forms of barcodes can also be effectively applied directly onto metal parts for permanent identification and scanning.

Increasing Safety with Unique Device Identifiers

Without the mandatory inclusion of UDIs on medical parts, FDA's ability to regulate and monitor the performance of medical devices after use is limited. If an adverse event occurs, the UDI can be used to identify not only the specific model of the device but also exactly when and where it was produced. In the unlikely event that a contamination issue or malfunctioning of an element occurs, this knowledge can be used to pinpoint where in the manufacturing process an error was made. Subsequently, steps can be taken to contact patients who may be at risk and prevent the issue from happening again. Laser marking is an effective and safe solution for marking UDIs directly onto the devices themselves, which is now a requirement for most devices under FDA regulations.

Tom Glass is president at Able Electropolishing, the world's largest electropolishing specialist offering electropolishing, passivation, titanium anodizing, and laser marking services. Able Electropolishing is an ISO 9001 and 13485 certified company serving a variety of industries, including aerospace, medical device manufacturing, food and beverage, automotive, and more.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)