This New Laser Tool Enables Coatings at the Nano Level

May 13, 2016

The new method was designed to enable coating processes to be controlled in real time--providing short laser pulses that can coat electronic medical devices and pharmaceutical products with layers in the nanometer range.

Kristopher Sturgis

|

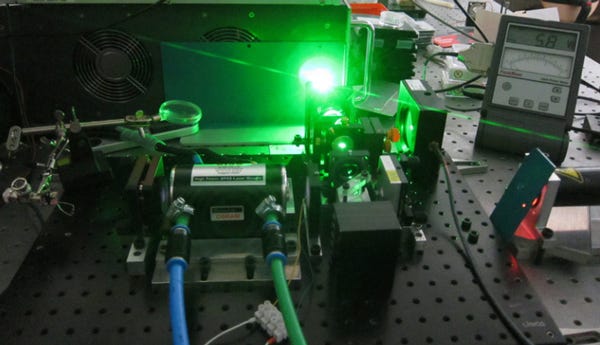

The polarization and intensity of the laser pulses can then be finely tuned depending on the thickness of the layer being applied. (Image courtesy of Vienna University of Technology) |

When it comes to designing electronic devices with layers at the nanometer scale, precision becomes the most crucial component of the manufacturing process. Thanks to a new technique developed by researchers at the Vienna University of Technology in Austria, manufacturers will have a new tool that uses laser pulses to provide unprecedented precision and quality control during the coating process in real time.

The new device, known as an inline ellipsometer, requires no moving parts and is relatively cost effective compared to other similar technologies. The device could have significant potential in a variety of fields, particularly when it comes to the manufacturing of photovoltaics. Solar cells are often made up of multiple layers that must be carefully crafted at varying degrees of thickness. The device could also be used to improve the manufacturing of battery and display technology, medical devices, and other electronic components.

"Our new technique images the object of interest with these different polarizations," says Ferdinand Bammer from the Institute for Production Engineering and Laser Technology at the Vienna university. "From the differences in these images, we deduce information about coating thickness. Other methods obtain thickness information only in a certain spot, or need much more time to get a mapping of the object, or are simply much more expensive. Our device is robust, small, contains no moving parts, and is very cost-effective."

The functionality of the device is actually quite simple. The inline ellipsometer produces laser pulses that are fired in quick succession, which are polarized using a crystal that oscillates thousands of times per second. The polarization and intensity of the laser pulses can then be finely tuned depending on the thickness of the layer being applied, and the coating can consist of essentially any material, provided that the material is somewhat transparent.

"Many devices in all disciplines are based on thin layers with a well defined thickness," Bammer says. "The latter is often crucial for the devices functionality. In medicine, for example, we mention protective or antiseptic coatings for devices. Inline thickness here is essential to check the functionality of the coating during production to adjust real time parameters. This will help manufacturers stay in the desired processing window and avoid waste."

For now, the group has developed a working prototype that can be attached to existing coating systems. The prototype has been tested on various coating systems already and has shown it can be used on various materials, providing all with the ability to customize the layer of thickness down to the nanometer. The next step is to begin rolling the device out to manufacturers for testing in real world environments.

"The technology is currently in an early stage, but we've been confronted with applications from all disciplines of science and technology," Bammer says. "It could even be an important tool for cheaper and reliable production of lab-on-a-chip devices, but it may turn out to be revolutionary for protective and antiseptic coating processes. The first installations are planned for this year, and depending on this, we estimate they could be in use in 6-10 months."

Learn more about cutting-edge medical devices at MD&M East, June 14-15, 2016 in New York City. |

Kristopher Sturgis is a contributor to Qmed.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)