Shape-Shifting Polymer Can Life 1000x Its Weight

February 12, 2016

University of Rochester researchers are further demonstrating the potential capabilities of shape-shifting polymers, creating a new polymer that can snap back into shape at human body temperatures.

Qmed Staff

|

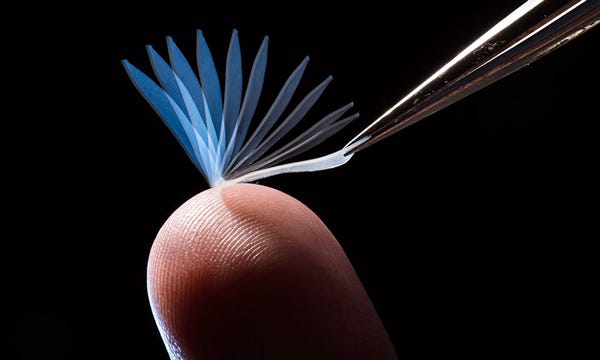

This multiple-exposure image shows a new shape-memory polymer reverting to its original shape amid exposure to body temperature. (Image courtesy of University of Rochester/J. Adam Fenster) |

A University of Rochester research team has developed a polymer that can be stretched, and then reverted back to its original shape by body heat alone.

"Our shape-memory polymer is like a rubber band that can lock itself into a new shape when stretched. But a simple touch causes it to recoil back to its original shape," Mitch Anthamatten, the University of Rochester chemical engineering professor who led the research team, said in a news release.

Anthamatten further elaborated to Qmed: "We've developed the ability to precisely tune the transition temperature. Our materials can remain soft and amorphous at room temperature for several hours after heating. This makes the material very easy to stretch, and upon stretching it crystallizes, and fixes a shape; but the formed crystals melt upon contacting the body."

Not only did they seek out a precisely tunable trigger temperature, but they also sought to optimize their polymer networks to store as much elastic energy as possible. Their shape-memory polymer can lift an object 1000 times its weight. A 1 g polymer strand the size of a shoelace could lift a liter of soda.

"Tuning the trigger temperature is only one part of the story. We also engineered these materials to store large amount of elastic energy, enabling them to perform more mechanical work during their shape recovery," Anthamatten said.

Anthamatten suspects the polymer could have a number of useful applications, both in medicine and in other areas. "The material may benefit applications that require large amounts of elastic energy to be released upon triggering; possibly sutures, stents, anchors, valves, etc. but also clothing apparel, foot-ware or protective equipment that can be triggered to ensure a tight fit."

The research was recently published in the Journal of Polymer Science Part B: Polymer Physics. The key behind creating the new polymer was to figure out to control crystallization that occurs when the material is cooled or stretched.

Here's how Anthamatten and colleagues describe the fine-tuning of the polymer's chemical recipe:

"We recently demonstrated that the elastic energy storage capacity of semicrystalline PCL shape-memory networks can be enhanced by controlling network architecture and chain connectivity. Topologically different networks were prepared from the same batch of three-arm PCL prepolymers. Although networks had the same chemical composition, they differed in chain connectivity. The most 'perfect' network was formed by base-catalyzed Michael addition of acrylate-terminated PCL prepolymers with multifunctional thiols."

The research is but another example of the potential around using shape-memory polymers in medical applications.

At the University of Texas at Dallas, a research team led by Walter Voit has demonstrated how to "program" shape-shifting thiolene/acrylates embedded with electronics to wrap around nerves as thin as 60 microns across. The dream is to someday treat neurological conditions with minimally invasive electrodes wrapped around nerves at strategic places in the body.

Voit, however, cautioned to Qmed last year that material science is not enough: "The material scientists who can be useful in this are the ones who have these really tight collaborations with neuroscientists and clinicians where you can understand not only materials, interfaces and electronics, but how they behave inside animals in the body in these specific biological tests."

One advantage of the Rochester-developed shape-memory polymer is that it uses well defined polymer networks with a predetermined molecular weight between crosslinks and a known crosslink functionality, according to Anthamatten. "Such networks offer superior toughness, and they enable more elastic energy to be stored during the shape memory cycle."

Find out about medical device materials innovations at BIOMEDevice Boston, April 13-14, 2016. |

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)