Reporter’s Notebook: Syensqo’s Healthcare Play

The spin-off company from 160-year-old Solvay has grand ambitions for continuing to bring its value proposition to the medical sector.

March 3, 2024

At a Glance

- Solvay has supplied healthcare sector for decades, so Syensqo’s products need no introduction

- Technology enables production of fluoropolymers without use of PFAS-linked fluorosurfactants

- Metal replacement in medical device design a specialty

In December of last year, global chemicals company Solvay announced the successful spin-off of its specialty business to the newly named Syensqo. Since then, the new company has been spreading the word about its portfolio and ambitions at various trade shows. I sat down with Benoit Verdickt, sales director for Life Solutions in the Americas, at Medical Design & Manufacturing (MD&M) West in Anaheim, CA, earlier this month to get a sense of Syensqo’s healthcare play. Here’s what he told me.

What’s old is new again

"Solvay is a 160-year old company — it all started with soda ash — and a few years ago leadership realized that it had several very different “children,” or entities, that required a different business model. It took us two years to split the company. We are now branded as a growth company and everything that comes with it, including investment strategies.

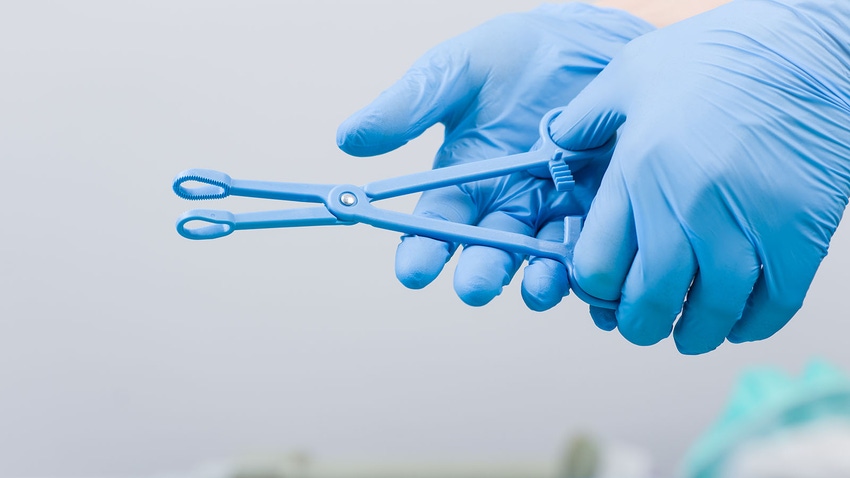

Today, Syensqo is a few businesses. Specialty Polymers is the biggest one, and that’s who you’re speaking with at this show. Within Specialty Polymers, healthcare is an important and strategic market for us, and we play in three main applications: Packaging with specifically high-barrier PVDC used in blister packs; hemodialysis with sulfones for blood filtration; and medical devices, which is a focus here at MD&M West, of course. Our markets include surgical instruments, both single procedure and reusable; implantables; connectors; filtration devices; and many other applications within the medical device market, where we leverage our specialty product portfolio — one of the largest in the industry — including PEEK and sulfones. It’s worth noting that we are the only company in the world producing sulfone-based implantables.

Solvay has been in the healthcare sector for several decades, so our products — Udel PSU or Radel PPSU, for instance — are well known within the industry. As Syensqo, the name of the game is working closely with our customers to solve their materials challenges. We love to work closely with design teams all along the product design cycle."

Building a bridge from PFAS to innovation

"We are heavily invested in the PFAS debate. The PFAS category encompasses a very broad family of substances, including thousands of different chemicals, all with very different profiles and properties. For Syensqo, PFAS is actually a story of innovation.

We are proud of our innovation power, as we developed a new technology enabling us to produce a wide range of specialized fluoropolymers without the use of fluorosurfactants — the PFAS substances under the most intense spotlight.

We have made a commitment to produce, by 2026, nearly 100% of fluoropolymers without fluorosurfactants. We believe that is a responsible approach and we are investing a significant amount of money to develop and improve our processes to transition to our new non-fluorosurfactant technology."

Plastics versus — and sometimes with — metals

"Metal to plastic is a big play for us, but it’s not just about eliminating metal. Rather, it’s about getting the best of both worlds. For example, a rod bender for orthopedic applications that we were involved with has some metal components — by overmolding the metal parts with a polymer we significantly reduced the weight of the device. Texture was also added to the polymer material, which made for easier gripping of the instrument.

We love to partner with OEMs because some of their design engineers know a lot about metals but not so much about plastics. It’s a different way of thinking when it comes to design, and it’s an area where we can bring our experience and support."

Sustainability is in our DNA

"Last September, we launched our ECHO product range, polymers with bio-based, recycled, and mass-balance-certified raw materials. Amongst them, Radel PPSU mass-balanced offers the same performance as traditional Radel, but through a certified mass-balance approach — a portion of the fossil-based feedstock is replaced with sustainable alternatives, lowering the carbon footprint of the material."

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)