PVC Film Avoids Phthalates, Resists Gamma Sterilization

November 27, 2012

|

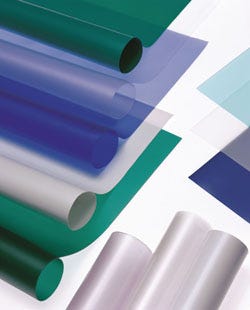

Teknor Apex's calendering process provides films with thickness uniformity, consistent physical properties, and thermal stability. |

While such phthalates as DEHP have historically been the most commonly used plasticizers in the medical industry to ensure that PVC compounds achieve the desired level of flexibility, toxicity concerns have been associated with phthalates over the years. As a result, manufacturers are demanding viable alternatives to phthalates such as citrate plasticizers, which exhibit excellent biocompatibility and cytotoxicity characteristics. Responding to this need, Teknor Apex Co. (Industry, CA) has developed a medical-grade PVC film that fits this bill.

"Citrate plasticizers provide similar benefits to phthalates for device manufacturers with respect to both the performance of the device as well as the manufacture and assembly of the device," remarks Rod Fischer, director of sales in Teknor Apex's vinyl division. A producer of both plasticizers and medical-grade PVC compounds, the company claims that its MF-165-J3R-79NT film is unique not only because it uses nonphthalate plasticizers but also because it can resist gamma irradiation--one of the most aggressive sterilization methods.

The new film's performance capabilities, according to Fischer, can be attributed to the company's calendering process. Fusing flexible vinyl compound and passing it through a series of synchronized nip rolls, this process offers thickness uniformity, consistent physical properties, and thermal stability. In addition, this manufacturing technique enables the company to offer the film with various embossed finishes.

"In our process, we deliver the melt-compounded PVC to the calender rather than to an extruder, as some film producers do," Fischer explains. "This calendering process enables us to produce films with well-developed and tightly controlled physical and mechanical properties, in addition to manufacturing the wider-width films available from a calender process." The technique also allows the firm to uniformly control the gauge, or thickness, of the film to meet customer requirements across the specified width. The films are available in thicknesses ranging from 0.006 to 0.020 in. and with widths up to 60 in.

Teknor Apex's R&D activities have shown that citrate plasticizers are the best all-around alternative to phthalate plasticizers for medical device applications, Fischer notes. "While other options are certainly viable, they involve different performance, manufacturing, and assembly considerations. And when all considerations are weighed, such noncitrate alternatives come at even a higher premium cost than DEHP."

About the Author(s)

You May Also Like