Introducing a Customizable Synthetic Spider Silk

June 9, 2015

After years of studying spider silk, researchers have created a synthetic silk that proves to be as versatile as it is strong.

Kristopher Sturgis

|

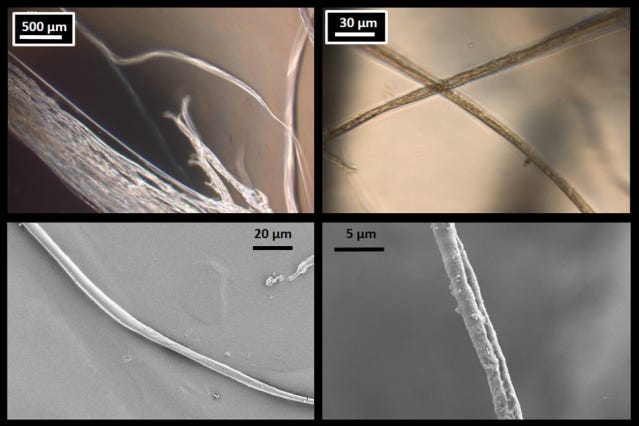

Lab-grown fibers boast high resolution. The above images from an optical microscope and the below images from a scanning electronic microscope show the precision with which the fibers can be produced. |

"Silk has remarkable properties," says Markus Buehler, MIT professor and head of the department of civil and environmental engineering, who recently had a report about a customizable spider silk published.

"Its high strength is larger than steel, it's very lightweight, and importantly is biocompatible. Silk is made from simple protein -- a biological feedstock that we hope can one day replace petroleum based sourcing," Buehler explains, whose group's research findings related to the wonder material were recently published in the journal Nature Communications.

Buehler believes that this research could pave the way for a whole new wave of fibers with improved characteristics beyond those of natural silk. Perhaps the true novelty of his work lies behind the possibility to design fibers with specific characteristics of strength, elasticity, and toughness. Not to mention a material that can be produced in a fashion that has many advantages over those of steel or concrete.

"The feedstocks for many high-volume materials such as concrete or steel rely on high-energy and high carbon emission processes," Buehler says. "Whereas silk-inspired materials can provide a carbon negative and low-energy route to production. The energetic advantage alone may be a key feature that drives economic success."

This project is perhaps the first to make use of molecular-level silk simulations, which make it possible to scan through a range of proteins. This enables the fiber stiffness to be fine tuned. Buehler says that controlling these properties could make it possible to create fibers that are even stronger than natural ones, simply because engineers it enables engineers to optimize the material for various applications.

"This should make it possible to design fibers with specific characteristics of strength, elasticity, and toughness by screening for a large variety of sequences and processing conditions that we now understand are key to achieving certain properties," he said. "This is critical to grow materials for specific purposes, or to add certain protein functions."

As for their application, Buehler believes that the biggest impact from his research will be in the ways that engineers can use this material for the design of various fiber-reinforced composites -- ranging in the medical field from new medical sutures to scaffolding for organ replacements.

"Ultimately, what we hope to achieve is that we can dial into any material property or combinations of properties, in a material by design approach," he says. "We now have a mechanistic model that we can use to design new materials that are distinct from earlier trial-and-error methods."

Silk has been used in the past for applications as varied as biomedical adhesives and orthopedic plates and screws.

Learn more about the medical device industry at MD&M East in New York City, June 9-11, 2015. |

About the Author(s)

You May Also Like