In Ortho Implants, Diamonds Are a Coating’s Best Friend

August 3, 2012

Future artificial hips and knees will face two interlinked design and materials challenges: They will have to be able to prevent the release of particulate debris while surviving in the body for years on end. However, as evidenced by the 2010 recall of DePuy Orthopaedics's ASR XL acetabular and ASR hip resurfacing systems, today's hip and knee implants can generate debris, leading to inflammation and the need for revision surgeries. Among the efforts to develop orthopedic implant coatings designed to prevent this phenomenon, researchers at the University of Alabama at Birmingham (UAB) are developing a diamond-based coating technology that they say can reduce particle generation to a minimum and vastly increase the longevity of orthopedic implants.

Future artificial hips and knees will face two interlinked design and materials challenges: They will have to be able to prevent the release of particulate debris while surviving in the body for years on end. However, as evidenced by the 2010 recall of DePuy Orthopaedics's ASR XL acetabular and ASR hip resurfacing systems, today's hip and knee implants can generate debris, leading to inflammation and the need for revision surgeries. Among the efforts to develop orthopedic implant coatings designed to prevent this phenomenon, researchers at the University of Alabama at Birmingham (UAB) are developing a diamond-based coating technology that they say can reduce particle generation to a minimum and vastly increase the longevity of orthopedic implants.

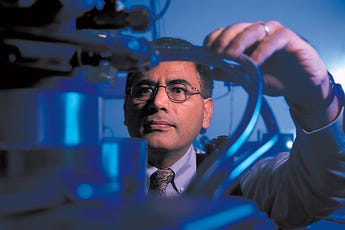

In the United States today, 328,000 hip replacements and 418,000 knee replacements are performed each year, remarks Yogesh K. Vohra, professor in the department of physics at UAB and director of the UAB Center for Nanoscale Materials and Biointegration. However, most of these implants contain particle-shedding materials. For example, current orthopedic coating technologies are often made from ultra-high-molecular-weight polyethylene, which sheds plastic particles over time. The resulting osteolysis, according to Vohra, leads to a revision rate of about 15%.

Diamond-based coatings, in contrast, do not display these negative performance characteristics, Vohra comments. In past studies, they have been shown to reduce wear debris volume markedly compared with first-generation alloy and polyethylene joint parts. In addition, laboratory tests indicate that they last longer than conventional implants by a factor of two to three. "If a conventional total joint replacement has a 10-year life span, our technology has a life span of more than 30 years," Vohra adds. "We have also subjected hip and knee implant materials to several million cycles of motion, and the wear is minimal.

The nanodiamond coating under development at UAB involves the deposition of a smooth nanostructured diamond film onto the metal surfaces of orthopedic implants. Capable of adhering to metals, the coating has the same roughness as that of the starting material. "Our contribution to diamond-coating technology has been in how we bond these diamond materials onto metals," Vohra comments. "If you cross-section the implant after deposition, the film does not come off because it adheres so well to the metal substrate."

To create the nanodiamond coating, the UAB team uses a microwave plasma chemical deposition system containing carbon-containing gases such as methane or hydrogen. (For more on this technology, see the following slide, "Diamond-on-Diamond: The Future of Orthopedic Implant Coatings.") Then, nitrogen is added to the reactor chamber. "Before the addition of nitrogen, the base metal surface contains very rough-looking diamond grains at the micron scale," Vohra explains. "After nitrogen treatment, the diamond grains measure roughly 50 nm, although individual grains can be as small as 5 to 6 nm. That's our real innovation. Once you grow the nanodiamond grains, you don't have to polish the surface. After deposition, this surface resembles a mirror." A mirrorlike surface is beneficial, he adds, because diamonds are a very hard material and thus difficult and expensive to polish.

Measuring approximately 5 µm in thickness, the UAB diamond coating does not suffer from wear, Vohra says. After 2 million rubbing cycles, it is still intact. In addition, because diamonds are resistant to acids, etching, or environmental effects, the coating is compatible with any type of sterilization method.

In addition to displaying excellent wear characteristics, the nanodiamond coating has been shown to be nontoxic to living cells. For example, in tests performed at UAB, scavenging immune cells called macrophages were exposed to nanodiamonds ranging in size from 6 to 500 nm at concentrations of 0 to 200 mg per millimeter. At concentrations of less than 50 mg per milliliter of solution--the concentration at which they generate debris--the nanodiamonds were not toxic to macrophages. Because of their small size and low concentration, nanodiamonds are thus engulfed by macrophages, causing the macrophages to release fewer inflammatory chemicals.

"Diamonds create particles," Vohra comments. "But suppose in the worst-case scenario that you have diamond debris in the bloodstream or in the tissue surround the implant. What will be the body's reaction? We have shown that whatever debris is created, it will be so small that it will be encapsulated by macrophages." While the UAB team would prefer to develop a coating that does not release debris, any debris that is generated by the nanodiamond coating will contain smaller particles than those generated by the metal or plastic implants manufactured today, Vohra adds.

To date, the UAB researchers have tested its nanodiamond technology on titanium-alloy implants, although they are pursuing efforts to develop a coating that can be deposited onto cobalt-chromium or steel. "But our argument is that if diamond is going to last forever, the base metal really doesn't matter," Vohra says. "We'll go with the metal that promises the best coating adhesion."

While the UAB team has a phase 2 grant from the National Institutes of Health (NIH) to produce a nanodiamond-coated dental implant in conjunction with Vista Engineering (Birmingham, AL) to treat temporomandibular joint disease, it has received a separate NIH grant to pursue the development of a coating for total joint hip and knee implants. However, the dental implant work is close to completion, while the work to develop the nanodiamond coating for use with hip and knee implants is still in the simulation phase.

"The temporomandibular joint market is very small," Vohra notes. "Maybe you're looking at 60,000 to 100,000 implants per year. But given the aging population, hip and knee implantations are expected to grow by 700% by 2030; an increasing fraction of Baby Boomers are getting joint replacements." To meet that growing need, the UAB researchers hope that existing orthopedic implants, such as those based on zirconium or polyethylene on cobalt-chromium, will be replaced with diamond-on-diamond implants displaying improved wear and longevity characteristics. --Bob Michaels

About the Author(s)

You May Also Like