From Here to 2020: Where Are Medtech Coatings Going?

April 2, 2013

While hydrophilic formulations are mature technologies that have been around for approximately three decades, they are still being reformulated to achieve a variety of different lubricious attributes. And while antimicrobial coatings--especially those based on the use of ionic silver--are commonly used in the medical device community, they still face a host of challenges. Meeting those challenges will be a major focus of medical device design and development efforts in the years to come.

Leading Coatings to Water

|

|

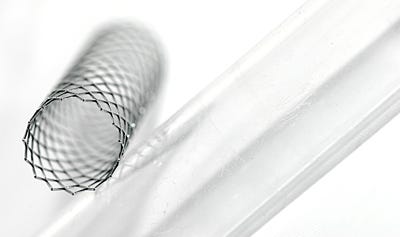

Catheters and stents are among the many medical devices for which hydrophilic and antimicrobial coatings are formulated. |

The purpose of hydrophilic coatings is simple, remarks Peg Palmer, CEO of Coatings2Go (Carlisle, MA), an affiliate of Surface Solutions Labs. "They were developed in the mid-1980s primarily to reduce patient trauma and to decrease friction caused by inserting a device into the body. Thus, they were associated with reducing tissue injury." And because it's easier to insert a coated device into the body, doctors don't have to work as hard, nor do they have to deal with swelling and body responses to injuries associated with the use of uncoated devices, Palmer adds.

Composed of urethane, acrylic, polyvinylpyrrolidone (PVP), polyethylene oxide, combinations of hydroxyethyl methacrylate, or other water-loving polymers such as acrylamides, hydrophilic coatings are available in a host of configurations. What most of them have in common, however, is that they can pick up water in the polymeric backbone placed on the device surface. But beyond being hydrophilic, different hydrophilic coating formulations go their own ways.

"When we set out to develop a hydrophilic coating, we decided that we wanted to produce something that's more permanent than other similar coatings," Palmer explains. To that end, Coatings2Go suspends and dissolves PVP--a hydrophilic polymer--into a water-dispersed supporting polymer consisting of either an acrylic or a urethane material with cross-linkable pendant groups on it. Then, as the material dries, cross-linkers take over and bind acrylic to acrylic, urethane to urethane, or acrylic to urethane around that hydrophilic polymer, creating a structure resembling a lattice. Within that lattice, the hydrophilic polymer is dispersed. "Thus, the hydrophilic polymer is effectively locked, a result of the interpenetrating nature of the structure," according to Palmer.

Although such associative forces as ionic attractions and van der Waals forces caused by spinning electrons help to bind the coating to the surface and supporting polymers, these forces can also become dissociative under heat or various in-use or storage conditions. Thus, an associative relationship between the coating-supporting polymer and the hydrophilic material can come undone under certain circumstances, causing a loss of hydrophilicity. "But because it is more durable in its slip and potentially also quite durable in its backbone, our covalently bonded coating prevents dissociative forces from reducing hydrophilicity," Palmer says. "While some molecular mobility in the interpenetrating network can remove loosely bound or lightly entangled material, most of the material is tangled up and is going to remain there." This entanglement and binding capability is the subject of several issued patents, while a further patent application is in its final stages of office action review.

All environments that have an aqueous nature, such as mucosal membranes and body orifices that have the capability of being flushed with water, are candidates for the types of coatings manufactured by Coatings2Go. Thus, its hydrophilic coatings are applied to many kinds of devices that are introduced into the body, including ureteral and urological catheters, neural and cardiac catheters and other introducers, guiding catheters, endoscopes, and esophageal scopes--medical devices that are used against wet or blood-filled tissue.

Of all the challenges facing the development of new hydrophilic coatings, business challenges loom large, according to Palmer. Hydrophilic coatings fall under the old business model of licenses and royalties, entailing huge up-front and continuing costs that favor large OEMs with deep pockets. This model makes sense if companies have intellectual property to protect, but it does not include enforcement power for expired patent holders. Thus, because many patents covering hydrophilic coatings are either old or expired, engineers or chemists could be allowed to develop new coatings based on past patents in order to avoid the royalty and up-front payments still required to access expired technology.

"Eliminating all of the up-front costs and hassles enables development engineers to obtain and use coatings for very little money. There could be an explosion of technology improvements that we cannot imagine today based on the old license and royalty model," Palmer adds. "If engineers with an idea are permitted to develop and test coatings without engaging in legal wrangling, signing nondisclosure agreements, or spending thousands of dollars as with the current business models, whole new technologies may emerge."

Getting the Bugs Out of Antimicrobials

Although Coatings2Go's chemistries are primarily used to formulate hydrophilic coatings for medical device applications, the company is also involved with the development of antimicrobial, antithrombogenic, and drug-delivery coatings. "If you look at orthopedics, surgical applications, and in-dwelling catheters, infection is a huge issue," Palmer notes. "For example, the infection rate associated with leaving a Foley catheter in the body for the full length of its potential useful life is supposed to lead to a 100% infection rate. Thus, when you add up all the untold costs--quality of life, amputations, bloodstream infections, hospitalizations, and the necessity for patients to take antibiotics--the need to develop effective antimicrobial coatings is enormous."

In an effort to meet this need, Coatings2Go offers a standard 10% silver sulfadiazine coating. This coating formulation, according to Palmer, has proven effective in urological applications. It can be modified and diluted, and it can also be made hydrophilic. In addition, the company provides a 10% heparin coating that is under evaluation for a number of different applications. Because its coatings are water based, the company can incorporate many bioactives that otherwise would be impacted by ultraviolet light or the solvents used in conjunction with other coating products. In addition, it has developed a coating that has delivered DNA to rabbit iliacs.

However, the impediments to developing new antimicrobial coatings are daunting. "Back in the 1980s and 1990s, SurModics had a great program for working antimicrobial additives into their coatings," Palmer says. "What they encountered was similar to what other people in the medical device industry were confronting: the need to perform large clinical trials to prove the efficacy of the material." Thus, introducing news coatings is encumbered by the need to perform volumes of expensive clinical research. In addition, because blood is different from urine and different parts of the body have different chemical challenges, enzymes, factors, and proteins, developing antimicrobial coatings is complicated, Palmer adds. The same holds true for the development of anticoagulation and antithrombogenic coatings.

The infections associated with implantable devices are often caused by biofilms that form on the device surface, Palmer explains. "Any surface that is colonized by bacteria can form a highly resistant saccharide-based biofilm harboring live bacteria. Biofilm prevention is a major challenge facing the medical device industry." Medical device experts, she adds, postulate that in order to prevent biofilm formation, a strongly leaching chemistry is required that can enter the biofilm and destroy the harboring bacteria. "You can kill the bugs, but if the bugs lie down on the device surface and become food for the next bug, then you've got a self-fulfilling prophecy--you're supplying the food chain." --Bob Michaels

About the Author(s)

You May Also Like