R&D DIGEST Joerg Lahann and graduate student Himabindu Nandivada analyze the surface of the polymer film using imaging ellipsometry.

July 1, 2008

A nonstick implant coating that can repel (or attract, in come cases) platelets and proteins might help prevent complications such as blood clots. The coating is part of an effort by researchers at the University of Michigan to create bioactive devices that interact with living cells.

The plastic coating is made from vapor rather than solvents or plasticizers. “The advantage of not using solvents is that we can exclude some of the molecules that are often toxic and known to initiate some of the undesirable inflammatory responses that [occur] with conventional biomedical coatings,” says Joerg Lahann, associate professor at the University of Michigan's (Ann Arbor) department of chemical engineering. Vapor-based coatings conform to small device geometries and preserve a device's shape.

The researchers coupled two processes to create and place the coating on devices—chemical vapor deposition (CVD) and atom transfer radical polymerization (ATRP).

“Mostly, researchers have worked on surfaces such as gold, silicon, and glass,” says Lahann. “The reason they were able to use those methods is that ATRP requires certain initiators, or anchors.”

|

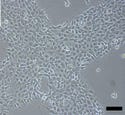

Chemical vapor deposition creates a nonstick coating on implants that helps to prevent inflammatory responses. |

The anchors were typically designed to bind to gold, glass, or silicon. By using both CVD and ATRP processes, the researchers can deposit initiator groups to any substrate or device. In addition to silicon and glass, the coating can bind to stainless steel and Teflon, for example.

“[The coatings] can be tailored to immobilize protein, sugar, and other biomolecules onto the surface. It's a coating that creates bioactivity,” says Lahann. These biomolecules act as anchors that can produce different responses depending on how they're used. “In this specific case, we were interested in preventing nonspecific binding of undesired proteins to the surface.”

To make the coating, researchers used a furnace to heat up the components and let the vapors cool on the device substrate. They were able to demonstrate that the coatings were protein resistant, which means that proteins cannot bind to the surface of the implant. The proof of principle also has implications on cell binding, because cells require the presence of a protein to adhere to a surface.

For the next stage in the development, Lahann wants to start selectively bringing in other anchor groups that will enable the researchers to attract certain proteins onto a surface.

“We would end up with a surface that has very high binding affinity to a specific type of protein, but at the same time prevent the nonspecific binding of proteins that you don't want,” he says.

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like