Blood Is No Match for Super-Nonstick Coating

March 24, 2015

A super-hydrophobic coating could prove useful for an array of medical device applications.

Brian Buntz

For years, Heinz has aired commercials trying to put a positive spin on the way its ketchup stubbornly clings to glass bottles. Plastic bottles make ketchup easier to dispense, but even then, it is seemingly impossible to get all of the ketchup out of the bottle by squeezing or gravity alone. Up to 15% of the condiment remains stuck in the bottle, according to Consumer Reports.

Enter a transparent nonstick coating, known as LiquiGlide, that could coat the inside of ketchup bottles and make it possible to empty an entire bottle in seconds flat by simply inverting it. And it's not just for ketchup.

The company hails the coatings as the "first and only permanently wet, slippery surface technology."

The coating could also be used for a variety of medical applications, including in medical tubing and stents, which can cause life-threatening complications when clogging. A video released by the company demonstrates how effective a LiquiGlide-coated tube is at repelling a blood substitute from its walls.

Blood Substitute in Flexible Tubing w/ LiquiGlide Coating from LiquiGlide on Vimeo.

The coating, which was invented at MIT, has given rise to an ambitious startup, which also happens to be named LiquiGlide (Cambridge, MA). Earlier this month, it won $7 million in funding, which it will use to expand and target virtually every industry imaginable: from aerospace to consumer packaged goods.

Ultimately, the technology could be "ubiquitous," proclaimed J. David Smith, the company's chief executive in The New York Times.

In healthcare, the company says its product will have a range of benefits. In addition to its use in stents and tubing, it could also boost the precision of delivering liquid drugs, which are often viscous and therefore hard to administer. The patented coating could also be coated to products like endoscopes and catheters to help make them easier to insert. It could also be used in over-the-counter medical products like toothpaste tubes.

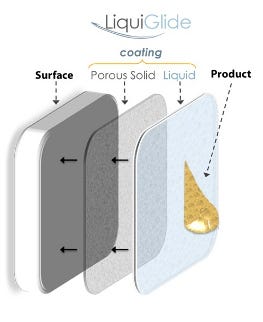

The coating differs from superhydrophobic coatings that have been developed thus far, which have a textured surface that forms a cushion of air that prevents liquids from clinging to it. The LiquiGlide coating does away with the layer of air and replaces it with another liquid.

There's no single LiquiGlide platform; it must be custom made for each application. The materials used in the technology also vary according to the application and the company isn't readily divulging which ones it has used thus far. While the company does not disclose the ingredients it is using, it does say they are derived from edible ingredients when it comes to food ingredients. While the company states on its website that its coatings for the food-and-beverage industry are made of edible plant-based ingredients, there is no information on what materials it plans on using for medical applications.

There's no single LiquiGlide platform; it must be custom made for each application. The materials used in the technology also vary according to the application and the company isn't readily divulging which ones it has used thus far. While the company does not disclose the ingredients it is using, it does say they are derived from edible ingredients when it comes to food ingredients. While the company states on its website that its coatings for the food-and-beverage industry are made of edible plant-based ingredients, there is no information on what materials it plans on using for medical applications.

To create a coating, the company selects a liquid that can be used with the desired application. Then, a solid textured material is chosen that adheres to the material used in the targeted application. Nearly any substrate can be coated, including glass, metal, plastic, and ceramic.

The liquid serves as a lubricant, and attaches with greater force to the textured material than it does to the liquid in the selected container.

The company plans on making prototypes for each application and, if it performs as planned, it will scale it up for commercial applications.

One of the first companies to ink a licensing deal with LiquiGlide is Elmer's, which, logically, will use the coating to make dispensing glue easier.

Learn more about cutting-edge medical devices at MD&M Philadelphia, October 7-8. |

Brian Buntz is the editor-in-chief of MPMN and Qmed. Follow him on Twitter at @brian_buntz.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like