A Practical Tubing Materials Alternative to PVC

February 27, 2015

Styrolution touts its diverse styrenics product portfolio as alternates to products commonly used in the medical device market, such as PVC.

Chris Newmarker

|

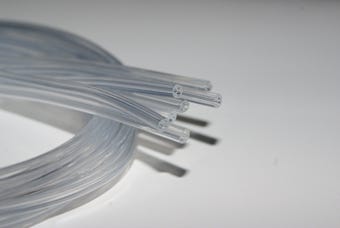

Microspec has partnered with Styrolution to use styrenics to replace PVC for its highly flexible multi-lumen tubing. (Image courtesy of Styrolution) |

Add styrenics to the list of medical device tubing materials being touted as alternatives to PVC and other commonly used products in the space.

Styrolution's Styroflex is a styrene-butadiene block copolymer (SBC) with the properties of a thermoplastic elastomer, and its Styrolux resins are a range of thermoplastic styrene-butadiene copolymers (SBC).

It was about a year ago that Microspec (Peterborough, NH), a market leader in medical tubing, announced it would partner with Styrolution (Frankfurt, Germany) to use the two materials to replace PVC for its highly flexible multi-lumen tubing. Such tubing makes it possible to administer different medications from one access point.

"Designers and manufacturers are looking for an alternative," says Alex Silvestre, global director of Healthcare & Diagnostic at Styrolution, which has its U.S. headquarters in Aurora, IL. The company is a joint venture between BASF and INEOS, with a focus on styrene monomer, polystyrene, ABS Standard and styrenic specialties.

Styrolution is already one of themarket leaders in providing PS (polystyrene) and ABS in labware and respiratory devices. In other device applications, its Terlux (MABS), Zylar (MBS), and Clearblend (MBS) lines are well established and recognized brands amongst some of the larger OEMs.

Offering another alternative material in the tubing space makes sense.

Polyvinylchloride (PVC) materials containing di(2-ethylhexyl)phthalate (DEHP) plasticizers are still common in a range of medical devices. But worries of DEHP's potential toxicity have caused Europe to crack down on its use in medical devices. FDA has not been as concerned, but that could change, too, Rudi Gall, managing director of polymer components company Raumedic, Inc. (Leesburg, VA), wrote in Qmed last year.

Silvestre thinks styrenics are a strong contender as an alternative. He listed off a number of reasons:

Materials such as Styroflex and Styrolux have a density advantage when compared to some other resins, so medical device manufacturers in some cases can use 20 to 30% less material.

For tubing applications, they can be used on existing machines including extrusion and injection molding equipment, avoiding a major manufacturing retooling.

There is improved bonding performance with components made of different materials.

Yellowing from e-beam or gamma ray irradiation sterilization is only temporary--which makes products made from styrenic materials aesthetically pleasing.

Styrolution's variousHD Service Packages also helps customers such as Microspec navigate the regulatory certifications and qualifications when it comes to adopting the new materials.

One drawback is that styrenic based materials cannot be steam sterilized because of their characteristic vicat temperatures. But many health providers are trending towards e-beam or gamma ray irradiation sterilization instead, according Silvestre.

"You need a material that meets the physical demands of the application, complies with existing regulatory standards, and is also aesthetically pleasing." Silvestre says.

Refresh your medical device industry knowledge at BIOMEDevice Boston, May 6-7, 2015. |

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like