A Look at Specialty Polymers for Surgical Robots

More than 5,000 surgical robots are installed worldwide – and that market is expected to grow at a double-digit rate over the next few years. This presents both challenges and opportunities for designers of surgical robots.

February 19, 2020

The surgical robot industry is developing specialized products for neurosurgery, spinal surgery and other medical procedures that require greater precision, flexibility, and control than is possible with conventional techniques. Today, more than 5,000 surgical robots are installed worldwide – and that market is expected to grow at a double-digit rate over the next few years. For the designers of surgical robots, this presents both challenges and opportunities.

The healthcare industry has discovered the numerous advantages of robotic surgery. For example, surgeons can benefit from having a higher viewing angle, less fatigue during long surgeries and the prolongation of their surgical careers since robotics can neutralize the effects of hand tremors, which increase with age. Patients can also benefit from faster recovery times, less postoperative pain and blood loss reduced scarring and fewer complications such as surgical site infection due to smaller incisions and better precision. These advantages, combined with the unique repeatability that surgical robotics offer, provide hospitals and clinics with a competitive edge in the healthcare marketplace.

Since the first documented use of a robot-assisted surgical procedure in 1985, robotic surgery has steadily evolved to include more complex systems and procedures. Today, this technology is being used to offer minimally invasive alternatives for surgical interventions such as those addressing spinal, orthopedic, neurological and cardiovascular issues. As the technology advances and greater awareness of its benefits continue to rise, the use of robots in the operating room is expected to become an increasingly popular choice for many other types of medical interventions, as well.

To support new designs and improve existing products, the surgical robot industry is using innovative approaches and advanced material technologies. In the medical device industry, designers have long replaced metals with plastics to reduce weight, lower costs and support single-use options. Yet robot-assisted surgery has additional requirements. Specifically, the designers of surgical robots need biocompatible plastics that can withstand high heat and resist repeated cleaning, disinfection, and sterilization. They also want greater design freedom and manufacturing flexibility.

Specialty polymers can meet these requirements and more. Not only are they replacing metals, but these materials are also replacing other types of medical plastics that are being pushed beyond their performance capabilities. For example, polysulfone (PSU) can be repeatedly steam-sterilized due to its higher heat resistance and hydrolytic stability than polycarbonate (PC), which quickly loses its impact properties after repeated steam sterilization. Polyphenylsulfone (PPSU), another specialty polymer, retains its exceptional toughness and impact strength after 1,000 cycles of disinfection and steam sterilization, outperforming polyetherimide (PEI) which experiences a drastic drop in physical properties after 100 cycles.

Specialty polymers also include polyetheretherketone(PEEK) and reinforced polyarylamide (PARA) compounds. PEEK is an ultra-high-performance plastic that combines outstanding resistance to harsh chemicals with excellent mechanical strength and dimensional stability. With their metal-like stiffness and strength, reinforced PARA compounds can also be used with surgical robots. PARA compounds also provide excellent resistance to mechanical stress and an exceptional surface finish, even with high glass fiber content.

Today, specialty polymers are used in surgical tools, the connections between surgical tools and mechanical arms, and in the housings for surgical robots. These high-performance plastics are also used in electrosurgery, a fast-growing medical field that includes forms of robotic surgery where electrical frequencies are used to destroy human tissue or make clean incisions. Electrosurgery not only eliminates the need for surgical tools like scalpels but also poses safety-related considerations. In all, many different types of specialty polymers are available, and properly understanding the benefits of each will enable designers to choose the right materials to solve specific application challenges.

Surgical Tools, Connections to Mechanical Arms, and Housings

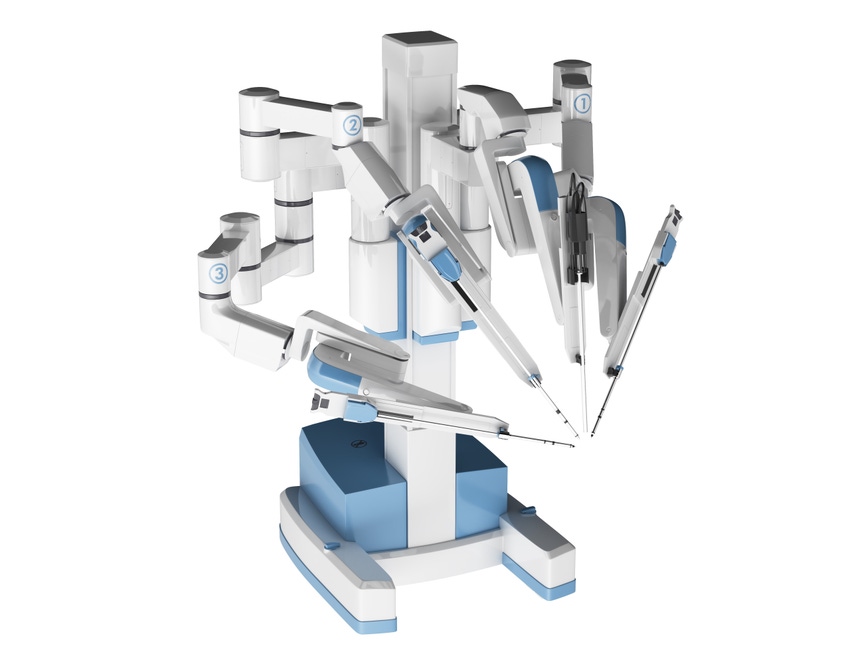

Surgical robots have mechanical arms that support the attachment of surgical instruments like scalpels. A separate arm supports the use of a high-definition camera. The surgeon is seated near the operating table and monitors a digital display for a magnified, three-dimensional view of the surgical site. The instruments that the surgeon controls come into direct contact with the patient and have historically contained significant amounts of metal.

For surgical tools, specialty polymers such as PPSU, PEEK and PARA compounds continue to replace metal because they allow greater design freedom, significant weight reduction and improved performance in challenging conditions. These biocompatible plastics also meet ISO 10993-1, an international standard for the biological evaluation of medical devices used by regulatory agencies such as FDA.

PPSU can be steam-sterilized over 1000 cycles without significant loss of mechanical properties, including impact strength. This makes it an excellent choice for medical devices needing superior toughness or extended service life after repeated autoclave cycles. It is also highly resistant to commonly used commercial washing solutions and hospital disinfectants.

PEEK is used in surgical tools because of its superior combination of chemical and fatigue resistance, strong mechanical properties and exceptional dimensional stability. Plus, it is virtually unaffected by repeated cleaning, disinfection, and steam sterilization. Glass-fiber-reinforced and carbon-fiber-reinforced grades of PEEK provide enhanced performance options such as higher strength and increased wear resistance.

Glass-reinforced PARA compounds are gaining wider acceptance for surgical instruments in single-use surgery kits, which are becoming increasingly popular because of ongoing efforts to prevent healthcare-acquired infections (HAI). These materials uniquely combine high strength and stiffens with an excellent surface finish, which makes it particularly attractive for applications where aesthetics is a key requirement. Materials optimized for sterilization using high-energy gamma radiation show no significant change in appearance or performance after sterilization.

Connections to mechanical arms also use PEEK and PPSU because of their mechanical properties, dimensional stability, and compatibility with harsh cleaning agents. Although biocompatibility may not be required, compliance with standards like ISO 10993-1 is preferred. In terms of manufacturing, surgical tools and connections to mechanical arms can be machined from extruded shapes. They can also be injection molded for faster processing times, lower manufacturing costs and the ability to design complex parts.

The housings for surgical robots also use specialty polymers. Because all surfaces in operating rooms are disinfected frequently, resistance to the repeated use of aggressive chemical agents is critical. Surface finish and color are important, too. Traditionally, the materials for surgical robot housings have included painted metal, especially in the case of very large surfaces, and PC, which is used typically for smaller surfaces and transparent parts. Today, specialty polymers with strong chemical resistance are rapidly replacing both metals and PC, while also reducing material weight and cost.

In terms of manufacturing, the plastic housings for surgical robots can be injection molded or thermoformed. Like injection molding, thermoforming supports molded-in color matching and textured tooling while eliminating the cost of painting and the subsequent paint chipping that can occur. Injection molding also supports product designs with fewer parts. By consolidating parts, designers can decrease labor costs, accelerate assembly times, and improve overall manufacturability.

For surgical tools, connections to mechanical arms and robot housings, color supports more than just brand identity and aesthetics. With surgical tools, color allows for the visual identification of instruments and their functions. This helps to eliminate the potential for confusion during a surgical procedure where different sizes of a device are used. Additionally, with the use of cameras and bright lights in the operating room, specialty polymers in darker colors and with lower gloss levels help to prevent light from reflecting off the instruments.

Robotic Electrosurgery

Robotic electrosurgery poses additional challenges for the designers of surgical robots. To protect surgeons and patients from electrical currents, the metal tubes that are used require electrical insulation. Increasingly, electrosurgical devices are also using monopolar frequencies with higher voltages and higher temperatures. By powder coating the metal tubes with PEEK, designers can achieve dependable protection.

PEEK provides the necessary insulative properties, high dielectric strength, and high-temperature and abrasion resistance. Further, the PEEK materials used to powder coat e-blades, for example, come in low-flow and high-flow grades with different particle sizes. These materials disperse differently at different sizes and can coat surfaces to a few thousandths of an inch. They also enable a uniform coating, which is important because variable thicknesses can introduce uncertainty about coating properties and safety.

Notably, electrosurgical devices are also subject to increased abrasion since multiple instruments may be used within the same small incision. If scraping or bending occurs, medical materials can lose their specialized properties and potentially put patients and doctors at risk. With the proper material selection and optimized design, however, specialty polymers like PEEK can help solve these challenges.

Much More Than Metal Replacement

For decades, metal was the preferred material in many medical devices because conventional plastics could not deliver metal’s combination of mechanical properties, durability and dimensional stability Today, most designers know about the growing use of plastics in healthcare applications but may not be aware of how specialty polymers are changing the design paradigm for surgical robots.

PEEK, PARA, and PPSU have a strong track record in metal replacement. They also enable the fabrication of more complex parts with greater design freedom and manufacturing flexibility. As the market for surgical robots continues to grow, designs that incorporate specialty polymers can deliver greater value to hospitals and clinics.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)