A Green Polymer Ten Times Stronger Than ABS

March 22, 2016

U.S. researchers have come up with a much stronger and potentially less expensive alternative to the conventional polymer.

Qmed Staff

|

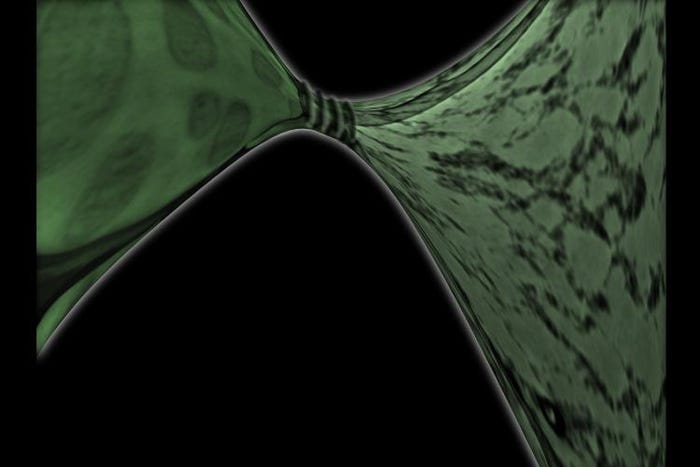

The tough plastic is made using 50% renewable content from biomass. Image from Oak Ridge National Laboratory, U.S. Dept. of Energy; conceptual art by Mark Robbins. |

ABS, or acrylonitrile, butadiene and styrene, is a workhorse polymer used for a range of medical device applications and in everyday objects such as car bumpers, many consumer product components, and Lego blocks.

Researchers at the Department of Energy's Oak Ridge National Laboratory have improved the properties of the material by removing styrene and replacing it with lignin, a natural polymer used to support vascular plants. Lignin, a byproduct from biorefineries and pulp and paper mills, also has the advantage of being in ample supply.

The natural lignin-bolstered polymer is at least ten times stronger than ABS. Known as ABL, or acrylonitrile, butadiene, lignin, the polymer could have the advantages of being not only stronger but also less expensive and cleaner to produce. "We can call it a green product because 50 percent of its content is renewable, and technology to enable its commercial exploitation would reduce the need for petrochemicals," says Amit Naskar of Oak Ridge National Laboratory.

The recyclable polymer can be produced without the use of solvents and it can be melted and reused three times while retaining its performance properties.

The material was described in the March 22 edition of Advanced Functional Materials.

Naskar and co-inventor Chau Tran have filed a patent application to cover the process used to make the material.

The researchers who developed this material plan on creating renewable thermoplastics that can go head to head with traditional petroleum-derived polymers.

Because lignin is naturally brittle, the researchers had to toughen it by combining it with soft matter.

The researchers combined a molten mixture of powdered lignin and nitrile rubber in their final material.

Learn more about cutting-edge medical devices at BIOMEDevice Boston, April 13-14, 2016. |

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)