Liquid-Nitrogen Cryogenic Machining Optimizes Manufacturing Efficiency

October 13, 2011

Coolants have traditionally been used to reduce the heat generated during the machining process--the primary failure mode for cutting tools. However, coolants have several drawbacks, including mist collection, workpiece contamination, and disposal costs. And while cryogenic machining has several advantages over conventional coolants, it has been regarded as too inefficient for large-scale machining operations. In response to this limitation, machine tool and systems provider MAG IAS LLC has developed an efficient cryogenic machining method based on the use of liquid nitrogen (LN2).

|

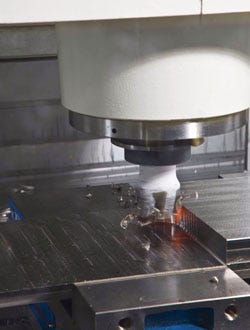

MAG's cryogenic machining technology relies on the use of liquid nitrogen to cool equipment and tools. |

"Our breakthrough is in the delivery of LN2 at its -321°F boiling-point temperature from the source feed system through the spindle for rotating applications or through turrets for lathe platforms," remarks George Georgiou, MAG's cryogenics product manager. "When it is introduced through tool holders and tools, it remains mostly in a liquid state." Because the LN2 is allowed to evaporate near the cutting edge of insulated tools, it promotes the dissipation of heat, which otherwise would soften tools and accelerate wear.

"In the past, the use of liquid nitrogen to cool cutting tools was inefficient," Georgiou comments. "It required high flow rates, and the cryogen vaporized before it could get to the cutting interface, losing most of its cooling ability." The new technology, in contrast, uses a low flow rate of 0.1 L/min per cutting edge.

The key to the new technology, Georgiou states, is the way that the LN2 is used. Prior cryogenic applications sprayed cryogens at the cutting area as if they were conventional wet coolants. The MAG application is more of a refrigerant application, enabling the cutting tool to remove the heat like a heat sink. "This mechanism allows us to speed up the process and take advantage of the 400°F difference between LN2 and traditional ambient wet coolants," Georgiou says.

By dissipating heat efficiently, cryogenic machining increases cutting-tool life and material-removal rates, according to Georgiou. For example, compared with conventional wet-coolant machining methods, the use of LN2 to machine titanium can result in up to a tenfold increase in cutting-tool life and a twofold increase in material-removal rates, depending on the application. And in addition to being cost-effective, nitrogen is a safe, breathable, nongreenhouse, nonflammable gas.

"MAG's cryogenic machining method is suitable for processing titanium, composite, or tough steel parts," Georgiou notes. "And in addition to its machineability, environmental friendliness, and economic advantages, this technology aids medical device manufacturing in another way--it's contamination free."

MAG IAS LLC

Erlanger, KY

www.mag-ias.com

You May Also Like