Measuring Porous Microbial Barriers, Part 2

The process is outlined in ASTM International Standard Test Method F2638.

PACKAGING

|

Insulating multiple wire paths with a polymer insulation applicator. |

ASTM International Committee F02, Flexible Barrier Packaging, completed balloting for a test method in June 2007. The test is used to rank porous packaging materials in sterile applications by their ability to hold out bacteria. The result of this balloting was test method ASTM F2638-07, Standard Test Method for Using Aerosol Filtration for Measuring the Performance of Porous Packaging Materials as a Surrogate Microbial Barrier. The test uses an aerosol of 1.0 µm-diam polystyrene spheres to measure the filtration efficiency of porous materials. Its predecessor, ASTM F1608-00 (2004), Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method) uses actual spores of a nominal 1.0 µm size for testing and can take several days to produce results. The new test method can provide almost instantaneous test results.

Part 1 of this article, published in MD&DI's May issue, discussed the history of test methods. This part looks more closely at the new standard method.

Method Summary

A porous packaging test specimen is placed into a sample holder to create a filter between the challenge stream and the filtrate aerosol stream. On the challenge side of the sample chamber, an aerosol of particles is presented to the surface of the test specimen. Airflow is generated through the test specimen, and laser particle counters enumerate the particles in both the challenge and filtrate aerosol streams. Particle enumeration in the challenge and filtrate streams can be performed sequentially, using only one particle counter, or concurrently, using two particle counters. A percent penetration value can be calculated from the challenge and filtrate particle count data. Monitoring and plotting percent penetration versus flow rate through the sample generates a typical filtration efficiency curve. The maximum percent penetration value and the flow rate at which it occurred are determined from the peak value of the curve.

Significance and Use

The results of this research demonstrated that testing the barrier performance of porous packaging materials using microorganisms correlates with measuring the filtration efficiency of the materials. The new method does not require the use of microbiological methods.

The incumbent test method for measuring microbial barrier, ASTM F1608, challenges test specimens at only one flow rate, a rate that is considered by many to be unrealistically high. In contrast, the new method generates filtration efficiency data over a range of flow rates that are considered to be more representative of the environment encountered by sealed packages during normal handling and distribution cycles.

When measuring the filtration efficiency of a porous packaging material, a typical filtration efficiency curve is generated. Because the arc of the curve is dependent on the characteristics of the individual test material, the appropriate way to compare materials is to use the parameter that measures the maximum penetration through the material (i.e., the flow rate at which the most particles pass through the sample).

Testing Apparatus

The main apparatus components of the new system are as follows:

An aerosol generator, which uniformly introduces polystyrene particles into the challenge airstream at a desired concentration.

The sample holder.

A manometer for measuring pressure drop across the test specimen.

One laser particle counter for enumerating the particles in both the challenge and filtrate aerosol streams.

A means of recording the data from the particle counters and pressure manometer.

The above list represents the most economical apparatus for the test. However, using only one particle counter requires that the challenge and filtrate aerosol streams be monitored alternately. As such, the time required to perform the test is doubled. In addition, using only one counter means that the value of the challenge counts must be calculated (as opposed to measured) during the interval when filtrate counts are being measured. This adds an extra step to data reduction. Adding a second particle counter enables simultaneous measurement of the challenge and filtrate aerosol streams, thereby reducing testing and data reduction time.

Some additional instrumentation (e.g., mass flow meters and pressure transducers) can make the test system more user-friendly. Although they add cost, such additional instrumentation can provide real-time information regarding aerosol generator flow, filtrate aerosol flow, vacuum generator pressure, and challenge vent pressure. Constant monitoring of these various system parameters can alert an operator to possible system malfunctions that could generate erroneous data.

In addition, direct measurement of the filtrate aerosol flow rate practically eliminates the need to convert pressure drop across the sample to flow through the sample, further reducing data reduction difficulty and time.

Development of the Method

Development of the standard test method was conducted in parallel with work to fine-tune the test unit. ASTM International was selected to develop the test because it is a consensus standards organization. The organization has a well-defined protocol for determining precision and bias and has developed many standards used in the medical device packaging community.

The draft test method was submitted to ASTM Committee F02.0, which is responsible for medical packaging materials and systems. The test method F2638-07, Standard Test Method for Determining the Microbial Barrier of Porous Packaging Materials (Aerosol Filtration Method Using Dual Particle Counters), was balloted three times at the subcommittee and main committee levels before being accepted.

Now that balloting and publication are completed, the method is available for purchase and will be included in the next publication of Part 15.10. Members of industry also plan to build additional test units and conduct a round-robin study to establish inter- and intralaboratory reproducibility.

The standard test method has been submitted to CDRH for inclusion in the agency's list of recognized standards. It will also be submitted to ISO technical committee TC198 (Sterilization) and working group WG7 (Packaging), which are responsible for the standard ISO 11607-1:2006, Packaging for terminally sterilized medical devices–Part 1: Requirements for materials, sterile barrier systems and packaging systems. This committee was recently responsible for activities that harmonized ISO 11607 with the CEN medical packaging standard EN 868 Part 1.

Comparing Microbial Barrier Tests

ASTM F1608-00 (2004) (the log reduction value [LRV] test) also produces an aerosol and challenges the test specimen by generating flow through the specimens. However, this test is conducted at only one flow rate—2.8 L/min—and instead of polystyrene spheres, the LRV test uses live organisms of nominal 1 μm size. Spores that penetrate the test specimens are collected for plating and enumeration on membrane filters.

Subsequent to plating, enumeration samples are incubated for a minimum of 24 hours. Colony-forming units (CFUs) and dilution factors are recorded for each sample. The LRV is then calculated by comparing the logarithm of the number of spores passing through the sample (the number of colonies on the plate) with the logarithm of the microbial challenge (the number of spores in suspension above or upstream of the sample).

The use of live organisms for ASTM F1608 means that care must be taken when handling specimens. The colonies are often difficult to maintain; they will sometimes die off or become unhealthy, making test results questionable. To reduce the possibility of generating erroneous results caused by contamination from normal bioburden, test specimens are typically sterilized before the test. There is also a need for constant decontamination of instruments and equipment. Thus, it is almost a requisite that this test be conducted at a biological testing facility or at a wet lab.

In addition to sterilization and setup time, the time required to conduct this test includes 15 minutes of actual sample exposure to microbial challenge; time to perform dilutions, if necessary; time to prepare plates; a minimum of 24 hours to incubate; and time to enumerate the CFUs. Then, data reduction can begin. Therefore, a typical turnaround time quoted by contract test labs (to conduct a test, generate the data, and write a report) is three to four days. In addition, it is important to note that this test is generally perceived as a rather noisy test, which could be attributed to the dilution process and how the CFUs are counted.

|

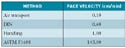

Table I. (click to enlarge) Comparative flow rates encountered by packaging materials during package distribution, handling, and testing. |

The most critical shortcoming of the ASTM F1608 test is the flow rate used during the challenge process. The flow rate for this test is fixed at 2.8 L/min, which generates a face velocity (stress) greater that 140 cm/min when accounting for the sample area. As mentioned before, this rate is unrealistically high when compared with theoretical and real flow rates encountered by packaging materials during actual package distribution and handling (see Table I).

At a flow rate of 2.8 L/min, inertial impaction is the dominant filtration mechanism. Inertial impaction occurs when a particle, as a result of its mass, deviates from the airstream flowing around a fiber and collides with the fiber. The effectiveness of this method of capture is directly related to the mass of the particle and the speed of the airstream. The higher the velocity and the mass of the particle, the greater the chance of it colliding with a fiber.

At the face velocity caused by this flow rate, spores cannot rapidly change direction with the air flowing through the sample. Their inertia tends to cause collisions with filter fibers, entrapping the spores. Because of this phenomenon, some porous materials appear to provide a much better microbial barrier than they actually do in real-world conditions.

The area of the ASTM F2638 test specimen is four times larger than the area of the sample required for the ASTM F1608 test. Testing the same amount of surface area using ASTM F2638 requires one quarter the number of replicates needed for ASTM F1608. Testing a larger area per sample also helps reduce sample-to-sample variability and thereby minimizes data scatter.

Using two particle counters, the ASTM F2638 test method requires only 3 minutes to obtain sufficient data for percent penetration calculation at a given flow rate or pressure differential. If one counter is used to alternately monitor challenge and filtrate particles, the testing time is 6 minutes. Data can be generated at five different flow rates in 15 minutes using a two-counter system. This is the same exposure time required to generate data for only one flow rate when using the ASTM F1608 test method.

When testing via ASTM F2638, data reduction can begin immediately after test completion. The population numbers are known immediately for both sides of the sample, and filter efficiency can be calculated and expressed in LRV (without the wait time usually required to count the downstream side). Because actual organisms or spores are not present, there is no need for decontamination, culture plating, or incubation. In addition, particle counters perform the actual enumeration. Unlike with ASTM F1608, there is no need for a biological test facility when using the ASTM F2638 test method. Therefore, this test can be set up and run almost anywhere.

In addition to rapid turnaround, the new test method can test at multiple flow rates that have been adjusted to imitate conditions of distribution and handling. Data have been generated demonstrating that the maximum penetration point of porous materials typically used for sterile packaging applications occurs at flow rates below those used in the ASTM F1608 test.

The Importance of Flow Rates

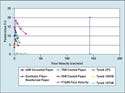

Figure 1 displays data collected while performing ASTM F2638. Percent of penetration is plotted versus test sample face velocity. Displayed with these data is the face velocity experienced by test samples during testing conducted in accordance with ASTM F1608. Note the extremely high face velocity used in the ASTM F1608 test. Refer to Table I and compare this face velocity with the typical velocity generated by air transport or routine handling. The range for face velocity used in the ASTM F2638 test is much closer to real-world stresses.

|

Figure 1. (click to enlarge) ASTM F2638 test data showing filtration efficiency curves with ASTM F1608 face velocity reference. |

Notice in Figure 1 that the maximum penetration points or curve peaks all occur at face velocities less than 5 cm/min. The maximum penetration points occur at a face velocity that is similar to those generated by real-life stresses.

The point of maximum penetration is where the microbial barrier properties of a porous material are challenged to their limit. Therefore, the maximum penetration flow rates or velocities most critical to selecting a barrier material.

When reviewing flow rates or face velocities, it is important to consider the various conditions a package may be exposed to during its life cycle. Every package encounters many levels of stress during its life cycle. However, these levels or face velocities are only part of the equation. Factors such as package volume also affect rate of pressure differential equilibration in a porous sterile barrier system. For example, a flat, two-dimensional package has very little air in the original configuration to evacuate and, as a result, very little air enters during the equilibration phase.

The surface area of the porous package material also affects face velocity. Less surface area for air exchange means greater face velocity during any equilibration process. Small patches or vents limit the space through which a sterile barrier system can equilibrate. Therefore, the forces are stronger, causing an increase in the face velocity.

Another variable to consider is package dimensions (L × W × D). A long, thin flexible sterile barrier system, such as a chevron peel pouch, exhibits different equilibration rates than a rectangular formed film design or a square rigid blister.

The clinical use of a sterile barrier system also subjects it to different stresses. For example, the pressure changes that occur to a flexible pouch when a nurse reaches into a box of small disposables, removes a handful, and carries them in her pocket are very different from the pressure changes experienced by a rigid blister package opened in an operating room setting.

Conclusion

What does this mean to a medical device packaging engineer? The new ASTM F2638 test method is an initial step toward establishing criteria and determining appropriate microbial barrier requirements for sterile packages. Additional work related to the relationship between package design, package volume, secondary packaging, clinical usage, environmental stresses and maximum penetration rates of materials will move the industry one step closer to adopting a universal standard for microbial barrier.

Although it will take time to generate the data required to shift the industry paradigm related to acceptable microbial barrier, the new ASTM F2638 test method gives packaging engineers a valuable new tool to rank various materials and begin questioning the appropriate level of microbial barrier for medical devices.

Curtis Larsen is a principal with Spartan Design Group and a package engineering consultant for Dupont Medical Packaging ( Wilmington, DE). Larsen can be contacted at [email protected]. Paul Herman is an application consultant for DuPont Nonwoven businesses as well as a technical representative for DuPont's Active, Industrial, and Medical packaging business segments. He can be reached at [email protected].

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)