Measuring Porous Microbial Barriers, Part 1

ASTM International Standard Test Method F2638 aims for deeper evaluations of the integrity of sterile packaging.

PACKAGING

|

ASTM has worked diligently to develop a microbial barrier test for terminally sterilized packaging. |

In 1997, the European Committee for Standardization (CEN) and International Organization for Standardization (ISO) introduced standards for materials and packaging for terminally sterilized medical devices. That work highlighted the need for a universally recognized microbial barrier test. The working groups decided that, in the absence of a widely accepted procedure for evaluating the integrity of the sterile package, the best way forward was to carry out separate tests for seal integrity, the package materials and films integrity, and the microbial barrier integrity of the porous materials.1

Although a number of tests were recognized for evaluating seal integrity, tests for determining the microbial barrier of permeable or porous materials were less abundant. Tests such as ASTM International F-1608,2 DIN 58953 Part 6 subclauses 2.14 and 2.15, and BS 6256 Appendix C (Methylene Blue) were all used, but not universally recognized. In addition, all of those tests take a long time, and results are not available for as long as three to four days in some cases.

Filtration Theory

The sterile barrier systems used to protect medical devices from bacteria and viruses are susceptible to ingress of suspended particles. Microbial spores can exist as individual entities or clusters, or they can be attached to inert particles (e.g., dust). The size of an invading particulate can range from 0.2 µm, for the smallest virus, to 100 µm, which is the size of the largest dust particle that can remain suspended in air for a significant length of time.

Filtration theory holds that materials that are permeable to air and gases remove particles from the airstream using three mechanisms: interception, inertial impaction, and diffusion.

Interception. This occurs when a filter fiber splits the airstream that a particle is following. The particle continues on its original path and collides with the fiber. Interception is therefore a constant particle removal mechanism that is a function of the material's fiber structure. It is independent of both the particle's mass and its velocity.

Inertial Impaction. This occurs when a particle, as a result of its mass, deviates from the airstream flowing around a fiber and collides with it. The effectiveness of this method of capture is directly related to the mass of the particle and the speed of the airstream. The higher the velocity and the mass of the particle, the greater the chance of it colliding with a fiber.

Diffusion. This is the interception of a particle with a fiber as a result of random particle movement (Brownian motion) and, for some materials, electrostatic attraction. The effectiveness of this capture mechanism is inversely related to the mass of the particle and the velocity of the airstream. The lighter the particle and the slower its velocity, the greater the chance of capture.

All three of these mechanisms are in operation at all flow rates and for all particle sizes. However, larger particles moving at higher flow rates are more likely to be trapped by inertial impaction, whereas lighter ones moving at slower speeds are more likely to be caught by diffusion.

The BTC Project

In the absence of an internationally recognized test to evaluate the microbial barrier of permeable or porous materials, a group of seven companies within the Sterile Barrier Association, previously known as European Sterile Packaging Association, formed the Barrier Test Consortium Ltd. (BTC) in 1998. Its aim was to develop a rapid, easy-to-use, microbial barrier test for porous medical packaging materials. BTC comprised the following companies:

Amcor Flexibles (formerly Rexam Medical Packaging).

Billerud (formerly Henry Cooke).

DuPont Medical Packaging.

Kimberly-Clark.

Oliver Medical (formerly Oliver Products).

Perfecseal, a Bemis Co.

Westfield Medical Packaging.

Members of BTC agreed that the new test had to meet certain key requirements. Specifically, the test had to be

Based upon established, scientifically sound filtration principles.

Applicable to the range and variety of commercially available medical packaging materials (including coated and uncoated papers, nonwovens, and cellulose and synthetic mixed papers).

Reliable, reproducible, and rapid.

Able to correlate with a recognized microbiological barrier test method (i.e., ASTM International F1608).

Fully definable and describable and, as such, able to support the requirement for microbial barrier performance as part of the CEN and ISO standards for medical packaging materials.

Following a call for research proposals, the project was awarded to Air Dispersions Ltd. (ADL), based in Manchester, UK. The project included the following tasks:

Defining the range of micro-biological barrier performances of commercially available porous packaging materials.

Selecting and adapting commercially available particulate filter test equipment and optimizing test conditions.

Establishing physical versus microbiological barrier correlations using materials of defined construction.

Confirming that the correlation applies to commercially available materials.

Specifying the particulate test method for defining micro-biological barrier performance.

To ensure that erroneous results were not obtained due to variations in commercially available materials, the initial work was designed to prove that a correlation existed using research-quality papers designed and produced by ADL. These papers had a high degree of uniformity and a wide range of porosity.

|

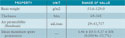

Table I. (click to enlarge) Range of properties for 16 sample materials used in tests conducted by ADL. Four of the 16 materials tested were adhesive coated. |

The next phase, a blind study, used 16 of 30 samples submitted by BTC members. The samples represented the range of porous packaging materials commercially available at the time. The range of properties for these materials is shown in Table I.

The specialized microbiological test used for the project was developed by ADL several years before work began on the BTC project.3 The test challenges the sample with standardized dispersions of microorganisms at a range of pressure differentials corresponding to overall flow rates ranging from 0.1 to 100.0 cm3/min/cm2. The range encompasses typical conditions experienced by medical packages during normal conditions of handling, distribution and storage.

The equipment used for this test was designed as a research instrument. It was highly specialized to allow for a wide operating range of flow rates. It also featured very sensitive control mechanisms for flow control, particle control, particle size, and enumeration.

Porous materials are basically filters or filtration systems. To test the effectiveness of any filter, a concentration of challenge media is forced through a sample of material by the pressure differential created across the filter sample. The extent of the flow rate depends on the amount of pressure or driving force to produce different flow rates. The extent of microbial penetration is determined at each flow rate by measuring the concentration of air-dispersed microorganisms both upstream and downstream of the material under test.

This test measures the extent of microbial penetration at each flow rate by measuring the concentration of air-dispersed microorganisms both before and after passing through the material. For a given test organism, the extent of penetration through the test sample depends strongly on the flow rate. This results in a maximum penetration value being obtained at a specific flow rate for a particular organism and packaging material. Endospores of bacillus subtilis var. niger are typically used. The maximum penetration value is a measure of the microbial barrier performance of the packaging material.

It is important to note that although this test gives an accurate result, it is a microbiological test and takes several days to complete. In addition, this test requires a high level of technical expertise and a dedicated microbiological laboratory. Although ADL considered the test to be a good research tool, it didn't meet the criteria requirement of being rapid.

To reduce equipment costs, an atomizer and an aerosol of polystyrene beads, which measure 1.0 µm in diameter, replaced the particle generator, the size classifier, and the neutralizer. This modification simplified the process, allowing for variable airflow capacity and a single-size, synthetic particle for the test medium.

The commercially available equipment selected for the BTC project was known to fulfill the criteria very well, enabling relatively inexperienced operators to obtain reproducible results for the physical particulate barrier performance of filter media in a matter of minutes. As with the microbiological test, a maximum penetration value is obtained.

To test medical packaging materials as opposed to filter media, it was necessary to design a special sample holder to use in conjunction with the equipment. Once the sample holder mechanism was available, researchers could identify percentage penetration of the most penetrating particle size (maximum particle penetration) for any material using synthetic substances as the test particle.

Basis for New ASTM Method

Scope of ASTM F2638-07 |

The BTC project was successfully completed in 2000 and formed the basis of the new ASTM International Standard Test Method F2638-07 (see the sidebar “Scope of ASTM F2638-07”).4 ADL was able to demonstrate correlation between results obtained using commercially available equipment for testing the physical particulate barrier performance of fibrous filter media and those generated using ADL's specialized microbiological test.3 Furthermore, the relationship extends over a wide range of commercially available packaging materials including coated and uncoated paper, and coated and uncoated nonwovens (e.g., Tyvek for sterile packaging). Such a relationship was not unexpected because both tests measure the effectiveness of materials to act as filter media.

Part 2 of this article covers the development of ASTM F2638-07 and provides a comparison of the new microbial barrier test method versus ASTM F1608, which is commonly called the log reduction value test. An in-depth look at the aerosol filtration equipment required to perform the new test method is also presented.

Curtis Larsen is a principal with Spartan Design Group and a package engineering consultant for Dupont Medical Packaging (Wilmington, DE). Larsen can be contacted at [email protected]. Paul Herman is an application consultant for DuPont Nonwoven businesses as well as a technical representative for DuPont's Active, Industrial, and Medical packaging business segments. He can be reached at [email protected].

References

1. ISO 11607-1:2006, “Packaging for Terminally Sterilized Medical Devices Part 1: Materials, Sterile Barrier Systems, and Packaging Systems” (Geneva: International Organization for Standardization, 2006).

2. ASTM F1608-00:2004, “Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)” (West Conshohocken, PA: ASTM International, 2004).

3. Alan Tallentire and Colin Sinclair, “Micro-biological Barrier Testing of Porous Medical Packaging Materials” (paper presented at the Meeting of the Society of Plastics Engineers [Scandinavian Section], Copenhagen, May, 1994).

4. ASTM F2638-07, “Standard Test Method for Using Aerosol Filtration for Measuring the Performance of Porous Packaging Materials as a Surrogate Microbial Barrier” (West Conshohocken, PA: ASTM International, 2004).

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)