Simulation Software for Biomedical Implant Design

For designing implants, Ansys and AnyBody can be coupled to provide a realistic and reliable prediction of medical device performance.

DESIGN

In the field of biomedical engineering, there is often much applicable engineering software to choose from but no single package that is comprehensive over the full spectrum of biomedical design. The Ansys (Canonsburg, PA) software suite, for example, has several advanced mechanical analysis tools, whereas the AnyBody (AnyBody Technology A/S; Aalborg, Denmark) software application provides a versatile rigid-body model of the skeleton as well as the muscles for detailed biomechanical analysis. For a situation such as evaluating an implant design, neither of these software suites provides a complete solution.

The best approach is to combine the benefits of both software programs by modeling the implant in both suites in an interdependent, coupled approach. While the AnyBody software simulation tool provides the musculo-skeletal motion and forces, the Ansys software provides the stresses and displacements in the implant subject to the motion determined by AnyBody. Therefore, it is necessary to couple both tools to facilitate the device design and development processes. This article offers a detailed explanation of each software tool and examines the coupling between them. A specific example is presented to illustrate the results.

Oftentimes a superior result can be achieved by combining two seemingly disparate fields. In the case of implants intended for the human body, it is reasonable to evaluate the mechanical behavior of the implant within itself as well as within the context of the human body. When these two modes are taken together, they should provide a more holistic picture of implant performance. For prototyping an implant, an ideal situation would be to combine the body dynamics from AnyBody with the finite-element analysis (FEA) of the implant in Ansys.

AnyBody is a powerful biomechanical analysis tool primarily concerned with musculoskeletal simulation. Included with the software are several projects that can be altered or built upon that involve the human body. These projects include a full skeletal system template with detailed muscle models. By applying inputs such as mechanical drivers or motion capture data to the system, the musculoskeletal system can be fully determined, and readings such as muscle and reaction forces can be extracted from the solution.

Ansys is a versatile software suite with several powerful engineering analysis components. One of its techniques is FEA, which is commonly used for structural analysis. Additionally, Ansys provides a design environment from which assemblies of parts can be created procedurally and then used directly in simulation. Because the assemblies are procedural, various parameters can be changed to fine-tune the design with little effort.

In this article, a spinal fixation implant is used to illustrate the coupling of the two programs. This implant is an advantageous test case for several reasons. Because the purpose of the device is immobilization, its interac-tions with the body are simple to model. Also, this spinal implant alters the body movement in a relatively small way, making the body model setup in AnyBody more manageable. Finally, because spinal fixation implants have been in use for years, public-domain implant models are available to provide a realistic example for study.

Background and Objective

|

Figure 1. (click to enlarge) A spinal fixation implant is used to illustrate the coupling of AnyBody and Ansys (a). The implant schematic (b) was used in the test case as a reference document. Source: U.S. Patent 4,653,481. |

The implant used in this test case is in the lower spine (see Figure 1a). The lower spine begins with the lumbar vertebrae, starting with the first lumbar vertebra, called L1, and continuing with that naming convention down to L5. The lowermost portion of the spine is the sacrum, the details of which are not important to this study. The pedicle region of each segment is the section of bone that connects the main vertebral body to the projections of bone behind the spine.

Spinal fixation implants are commonly used to treat a variety of conditions such as herniated disks, fractures, or injuries in the vertebrae themselves, as well as to treat scoliosis and arthritis in the joints of the spine. The objective of the implant is to immobilize the two adjacent vertebrae with the intent to either reduce pain or to ensure proper healing. When permanent fusion is desired, the implant is often supplemented with a bone graft between two vertebrae, where the body's growing bone will propagate and fuse the two vertebrae naturally. Affixation of the implant to the bone is accomplished by putting screws through the pedicle region of each vertebra. These pedicle screws then become the foundation of whatever bracing apparatus the implant will use.

The implant chosen for this study uses a clamp perpendicular to the pedicle screws that braces the two intervertebral rods running through the screw head. These rods are connected to the adjacent pedicle screw head in the next vertebra. Figure 1b shows a schematic from U.S. Patent 4,653,481, which is the reference document for the implant used in this study. Although the implant pictured runs across five vertebrae, the test case implant runs across only two. This is a common configuration for spinal fixation implants and simplifies the simulation model.

The main objective of this study was to improve and validate the coupling between Ansys and AnyBody by including both software programs in a simulation of a sample implant. The work done in coupling the two programs should be long term and applicable to future such simulations. Because this was initial research, the coupling began as a one-way process, from AnyBody to Ansys. Future research could improve on the initial results.

Setting Up the AnyBody Component

The AnyBody project first needs to be set up for the test case implant. Research suggests that the moments on spinal implants are more pronounced during ventral flexion (bending over) and lateral bending (bending to the side). Because extreme stresses are ideal for testing the limits of an implant, an ideal simulated body movement would combine each of these elements into a single motion.

|

Figure 2. (click to enlarge) This graphic shows an AnyBody project that is ready for use or modification. This illustration shows the subject bending from side to side while holding a 10-kg box. The posture for this movement is bent over, and the primary movement is lateral bending, which should significantly stress the spinal implant. |

AnyBody provides a repository of projects with a variety of motions for ready use or modification (see Figure 2). One of the studies included is the standing lift motion, which fulfills the above criteria nicely. In this study, the subject is holding a 10-kg box while bending from side to side. The posture for this movement is bent over, and the primary movement is lateral bending, which should stress the spinal implant significantly. Other good candidates from the standard AnyBody library include the standing model circumduction, in which the standing model goes through a back-stretching movement that includes ventral flexion and extension as well as lateral bending, or the egress, in which the human model is stepping out of a car.

Because the movement of the spine vertebrae is restrained by the implant, the movement must be similarly restrained in the human body model. Because the model is assuming perfect immobilization in the absence of true coupling between the software programs, the segments are set stationary to each other. AnyBody uses a spinal rhythm model for determining individual vertebra movements by approximating the segments as a bending beam with variable stiffness. In this way, the vertebrae positions are determined by constraint equations that use the thorax-hip angle as the main input. The spine keeps its natural shape when bending. To effect the immobilization from the implant, the stiffness coefficient between the two vertebrae was set to zero. This ensured that after these vertebrae assumed their initial position, they would not move relative to each other.

A Generalized Tool

To aid in this coupling, a generalized tool was developed in-house at Ozen Engineering Inc. The tool, tentatively titled Any2Ans, has several capabilities that aid the process of bridging Ansys and AnyBody. Written in Java, the tool is portable across all platforms. The main file of the standing lift study is the starting point for the entire implant case study and includes references to several other files, which can refer to still more files. Any2Ans reads through this master file, and based on the files it refers to, it builds an internal representation of the entire AnyBody project. The Any2Ans program searches this representation for the physical elements used in the study and extracts them. The element geometries, including the bones, are converted from the internal format that AnyBody uses into the very common STL file format for future use. Any2Ans then runs AnyBody in batch mode and sets it to output the movement data of the geometries extracted from the study. The results are read and the model that is created is displayed by the program.

|

Figure 3. (click to enlarge) Any2Ans runs AnyBody in batch mode and sets it to output the movement data of the geometries extracted from the study. The results are read and the model is displayed by the program. After the AnyBody result has loaded, bone geometries may be selected or excluded, depending on the requirements of the simulation, and exported into a single STL file. |

After the AnyBody result has loaded, bone geometries may be selected or excluded depending on the requirements of the simulation and exported into a single STL file. The entirety of the movement can be replayed within the program window, and the exported geometries will be in the arrangement shown in Figure 3. The motion is converted to the appropriate coordinate system and output into an XML file readable as a load history in Ansys. Any motion exported is relative to the arrangement of the resultant STL file and may be shifted and looped as needed.

In this particular case, a mistake was made. Although Any2Ans includes a feature to start the movement at a selected neutral position while still undergoing the full motion in the study, this feature unfortunately went unused. The motion in the AnyBody study starts at the end of a lateral bend, and the model proceeds to bend the opposite way. Because the implant was later built into this position at the end of a bend, the result may be artificially high stresses in the analysis as the human model bends fully the other way.

Creating the Ansys Simulation

|

Figure 4. (click to enlarge) The implant is recreated from the detailed drawings in the patent document and affixed to the vertebrae. The design is created in a procedural manner so the design parameters of the device can be altered. The model is advanced from the design stage to the simulation stage, in which specific types of analysis can be set up. |

The exported bone geometries are surfaced, meshed, and converted into volume bodies in the Ansys mesher software before being imported to Ansys DesignModeler (see Figure 4). This is necessary because the AnyBody bone geometries are primarily designed for visualization purposes and can have surface discontinuities or abnormalities that would cause problems with FEA. In cases in which the bones themselves are directly undergoing FEA, more-detailed bone geometries would be desirable. The implant is re-created from the detailed drawings in the patent document and affixed to the vertebrae. Ansys creates the design using a step-by-step process so that the parameters of the device can be altered and refined with little extra work. An alternative version of the implant with thicker intervertebral rods is created for simultaneous analysis.

From the design stage, the implant model advances to the simulation stage at which point specific types of analysis can be set up. The goal is to apply boundary conditions to the vertebral bodies and observe their effect on the implant itself, as noted here:

L1: The engineering data output by Any2Ans provide displacements and rotations for each bone.

Between L2 and L1 joint: A spherical joint is created, the coordinates of which are duplicated from AnyBody. The reaction forces on this joint from AnyBody are applied. This process is done manually but could be implemented as a feature in the Any2Ans tool.

L2: Unconstrained.

Between L3 and L2 joint: A spherical joint is created, with the coordinates again coming from AnyBody. This is the joint that the implant bridges, and it is left unconstrained.

L5–L3: Any2Ans exported movement data are applied.

The contact points are set to reflect how the implant would function mechanically. The contact between the bone and implant is set to be perfect bounding. Affixation of the implant to the bone, although certainly significant and the subject of a large body of research, is beyond the scope of this article. The implant material selected for the study is 316L stainless steel, for which there are data on alternating stress-cycle response and strain-life information, allowing long-term reliability evaluation of the implant based on this simulation. In this study, the static simulation was set up and run for both implant variations.

Results

|

Figure 5. (click to enlarge) The comparison of joint reaction forces between the AnyBody-generated values of the L1/L2 joint and the Ansys- generated reaction forces of the L2/L3 joint showed that the implant provides significant support in its intended area. |

The comparison of joint reaction forces between the AnyBody-generated values of the L1–L2 joint and the Ansys-generated reaction forces of the L2–L3 joint indicated that the implant provides significant support in its intended area (see Figure 5). This result also supported the validity of the simulation, with the implant having the desired effect on the body.

The stresses on the implant seemed extremely high at first, with the stress reaching 1.545 GPa, roughly three times the ultimate strength of the material. Upon further inspection, the high stresses were found to be heavily localized around a small number of elements near contact surfaces and thus could be ignored. However, the implant still showed a significant amount of yielding in several places, hovering at or below a safety factor of one in several areas. In this simulation, the 316L stainless steel proved insufficient for the needs of the thin-rod implant.

|

Figure 6. (click to enlarge) Although there might have been some marginal improvement in the rods themselves, the clamps holding the thick rods developed more stress than before. There were also extreme contact forces spread out over an area in the lower right of the implant that had not been present in the thin-rod variant. |

The thick-rod variant of the implant fared similarly. Although there might have been some marginal improvement in the rods themselves, the clamps holding the rods developed more stress than before. Extreme contact forces were spread out over an area in the lower right of the implant that had not been present in the thin-rod variant (see Figure 6). These stresses suggest that a great amount of wear will occur in this area and, therefore, wear should be considered during the design process. Overall, the thicker rods did not help the performance of the implant much.

|

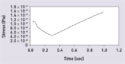

Figure 7. (click to enlarge) The general trend starts to follow the same curve as the joint forces on the implant pictured earlier, but it is soon overpowered by a completely different linear increase in the maximum stress on the material. Even though these maximum stresses are the artificially high contact forces, the effect is still there. |

The major source of error in the study was probably the nonneutral starting position of the implant. This had the effect of constantly increasing the bending of the implant even as it was moving toward the neutral position. The graph in Figure 7 shows the maximum equivalent stress for the implant, which seems to bear this out. The general trend starts to follow the same curve as the joint forces on the implant shown earlier: it is soon overpowered by a completely different linear increase in the maximum stress on the material. Even though these maximum stresses are the artificially high contact forces mentioned earlier, the effect is still there.

Conclusion

The coupling of Ansys and AnyBody software leads to new ways of analyzing medical devices. In this study, a spinal implant was tested not by a best-guess maximum moment, force, or stress but by a specific motion of the human body. The results achieved in this case were satisfactory, but there are improvements that could be made, both to this particular study and to future studies using this general procedure.

The next step for this type of work is to implement two-way coupling. Currently, the coupling process is one way, with Ansys being completely dependent on AnyBody, and with AnyBody being completely unaware of Ansys. This requires that the AnyBody portion be set up with the necessary assumptions so that nothing that happens in Ansys will affect the human body model. If the process could be changed to make the programs interdependent, many new and interesting cases could be rigorously analyzed. In this case the implant was a rigid fixation device, but a flexible spinal fixation device could be modeled, with the movements of the body coming from AnyBody and the articulation or deformation of the device from Ansys. The process would probably be iterative, with the results being passed between the two programs until they converge on a set of values. The current results show that there is a benefit to refining this coupling process.

In summary, the software tools that can predict musculoskeletal movement by AnyBody Technology and the FEA tools by Ansys Inc. can be coupled to assist in the design and development of medical devices. The AnyBody Technology software tools predict the musculoskeletal movement, and the Ansys FEA software tools predict the stresses, strains, and ultimately the fatigue life of the medical device. The coupling of these tools enables more realistic and more reliable prediction of medical device performance.

Metin Ozen is president of Ozen Engineering Inc. (Sunnyvale, CA). He can be reached at [email protected]. Can Ozcan is project manager and Kaan Divringi was a summer intern for the company.

Copyright ©2008 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)