Extrusion

April 9, 2009

Originally Published MPMN April 2009

OUTSOURCING OUTLOOK

Extrusion

Click to enlarge |

Apur Lathiya, vice president of sales and marketing, Extrumed, Placentia, CA. |

The extrusion of tubing for medical devices is constantly changing. Device engineers are pushing the envelope with new tubing configurations, demanding thinner walls, smaller diameters, and softer materials. Advances in material formulations and stricter quality requirements from OEMs are also challenging tubing suppliers.

While new extrusion equipment, process control technologies, metrology equipment, and tooling designs help manufacturers meet challenging configurations, operator and engineering skill is necessary to successfully manufacture extruded products. Operator training and an understanding of tooling design and material melt-flow characteristics are more important perhaps than utilizing the proper extruder and ancillary equipment.

Material formulations are also constantly evolving. Whether they use new copolymers such as polyurethane-silicone, surface-modified and antimicrobial polymers, or customers’ proprietary compounds, suppliers must learn how to design tooling and extrude materials to meet customer specifications.

In addition, stricter FDA oversight of OEMs is requiring suppliers to adapt their quality systems, data collection capabilities, and process controls. As tubing operations become more data driven, suppliers, to become approved, must provide a range of reports, including process failure mode effects analyses, control plans, and process capability statistics.

As the industry evolves and new medical devices are developed, OEMs should continue to view their suppliers as an extension of their own manufacturing. In turn, tubing suppliers will have to continually evolve to keep pace with the ever-changing needs of the industry.

Extruder Offers Medical Device Design, Engineering, and Manufacturing

Click to enlarge |

Providing integrated extrusion services from product design to fulfillment, a vendor offers medical device engineering, manufacturing, and logistics capabilities. The ISO 13485–certified and FDA-registered company specializes in the manufacture of sterile single-use medical devices, offering tool design and manufacture, assembly, packaging, and sterilization services. In addition, it provides global supply-chain and logistics management for extruded products. The company’s manufacturing facility is equipped with Class 100,000 cleanrooms.

GPS China

Galway, Ireland

www.gpschina.ie

Supplier Extrudes Single- and Multilumen Tubing

Click to enlarge |

A service provider offers precision thermoplastic medical extrusions that are produced in a pyrogen-controlled Class 100,000 cleanroom. The ISO 9001:2000– and ISO 14001–certified company specializes in single- and multilumen tubing, thermobonded paratubing, coextrusions, and custom profiles. It also offers secondary operations and subassembly services. Specializing in medical-grade custom flexible and rigid tubing, the vendor uses USP Class VI materials, including PVC, non-DEHP, PE, PP, PU, PC, HIS, radiopaque materials, and PVC alternatives. Additional offerings include statistical process control documentation, on-line measurement, and in-house wire EDM CAD/CAM services.

Filtrona Extrusion

Alpharetta, GA

www.filtronaextrusion.com

Contractor Specializes in Extruded Disposables

Click to enlarge |

A contract manufacturer specializes in extrusion molding of components for sterile disposable medical devices such as infusion sets, easy-to-fill disposable elastomeric infusion pumps, and accessories used for antibiotics, chemotherapy, and pain management. The company’s infusion kits are latex- and DEHP-free, CE marked, and manufactured in compliance with QSR and ISO 13485:2003 standards. Its pumps are available in soft- and hard-case versions with fill volumes ranging from 50 to 500 ml, infusion rates from 1 to 500 ml/hr, and accuracies to ±10%. In addition to manufacturing services performed in FDA-registered facilities, the supplier offers a range of extrusion consulting services, including quality and regulatory expertise, process validation, and project management. It also assembles and packages extruded products.

First Medical Source

Laguna Niguel, CA

www.firstmedicalsource.com

Manufacturer Provides Extruded Balloon Tubing

Click to enlarge |

A vertically integrated provider of outsourced products for catheter manufacturing offers balloon and catheter design and development, extruded balloon tubing, balloon contract manufacturing, catheter contract manufacturing, and a line of balloon catheter production and testing equipment. The ISO 13485:2003– and ISO 9001:2000–certified company operates multiple Class 10,000 and Class 100,000 cleanrooms in three facilities. The manufacturer’s extrusion process produces balloon tubing with consistent characteristics, delivering precise wall thickness and inner and outer dimensions while reducing gel spots. Its tubing can improve balloon performance properties such as minimal wall thickness, burst pressure, and fatigue. Offering a range of standard and custom tubing sizes, the company’s tubing lots come with complete documentation, including certificates of compliance, dimensional and visual inspection reports, and tensile test reports.

Interface Catheter Solutions

Laguna Niguel, CA

www.interfaceusa.com

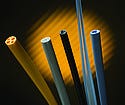

Vendor Focuses on Vascular and Cardiac Applications

Click to enlarge |

A contract manufacturer offers a range of tubing services, including design, engineering, material selection, prototyping, volume manufacturing, secondary operations, and supply-chain management. Its core markets are vascular intervention, including coronary, peripheral, and neurovascular applications, as well as cardiac rhythm management, including neurostimulation, endosurgery, and vascular-access products. The company manufactures catheter, lead, and device tubing fabricated from virtually any thermoplastic. They are available in many configurations, including coextrusions, multilumens, and tapers. In addition, the company offers irradiated balloon tubing and polyolefin heat-shrink tubing. The supplier also complements its tubing products with value-added services, including rapid extrusion, mechanical testing, pressure testing, process validations, and inventory management.

Extrumed

Placentia, CA

www.extrumed.com

Copyright ©2009 Medical Product Manufacturing News

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)