Dispensing equipment

May 1, 1999

Dispensing equipment

Programmable unit

A digital programmable liquid dispenser offers high-speed dispense control with the ability to cycle up to 900 times per minute. Up to six time settings can be programmed between 0.01 and 99.99 seconds and can be shown on an LED. The DD305 unit provides a repeat accuracy of 0.1%, an adjustable vacuum feature to control fluid drips between dispense cycles, and consistent deposition of materials. Microprocessor-based control, a 24-V-dc filtered and regulated power supply, an automatic and manual mode switch with LED indicator, and a dual-regulated air outlet are features of the unit. I & J Fisnar Inc., 2-07 Banta Pl., Fair Lawn, NJ 07410-3002.

A digital programmable liquid dispenser offers high-speed dispense control with the ability to cycle up to 900 times per minute. Up to six time settings can be programmed between 0.01 and 99.99 seconds and can be shown on an LED. The DD305 unit provides a repeat accuracy of 0.1%, an adjustable vacuum feature to control fluid drips between dispense cycles, and consistent deposition of materials. Microprocessor-based control, a 24-V-dc filtered and regulated power supply, an automatic and manual mode switch with LED indicator, and a dual-regulated air outlet are features of the unit. I & J Fisnar Inc., 2-07 Banta Pl., Fair Lawn, NJ 07410-3002.

Dispensing modules

A company provides custom dispensers for medical device manufacturing and secondary medical dispensing applications. Applications include automated dispensing of lubricants for aerosol drug-delivery systems and dispensing 50-nl volumes of liquids. Modules and options include 1-, 2-, and 3-axis Cartesian motion modules; a selection of dispensing pumps and valves; height sensors; heated tips and tables; and the company's True Volume piston positive-displacement pump. Creative Automation Co., 11641 Pendleton St., Sun Valley, CA 91352.

Sealant applicator

In as little as two seconds, a machine can apply liquid sealant to threaded valves and fittings to prevent leaks. The ECSII, designed to operate from a vertical axis rather than a horizontal position, uses gravity to help feed a consistent bead of sealant without a messy overflow. The system automates liquid sealant application with batch processing. A palm valve that activates the system with only 4 oz of pressure is designed to reduce the risk of repetitive-motion injuries. Federal Process Corp., Advanced Adhesives and Sealants Div., 24400 Highpoint Rd., Cleveland, OH 44122.

In as little as two seconds, a machine can apply liquid sealant to threaded valves and fittings to prevent leaks. The ECSII, designed to operate from a vertical axis rather than a horizontal position, uses gravity to help feed a consistent bead of sealant without a messy overflow. The system automates liquid sealant application with batch processing. A palm valve that activates the system with only 4 oz of pressure is designed to reduce the risk of repetitive-motion injuries. Federal Process Corp., Advanced Adhesives and Sealants Div., 24400 Highpoint Rd., Cleveland, OH 44122.

Adhesive dispenser

Designed as an alternative to solvent dispensing, a UV-curable adhesive dispenser offers repeatable and quick dispensing onto PVC, ABS, and other medical polymers. The UVAD's custom bushings dispense adhesive on internal or external surfaces of medical tubing or components. The system was designed to minimize environmental contamination and prevent wasting of adhesive. TechnoMed Inc., 59 Stiles Rd., Salem, NH 03079.

Dispensing workstations

A variety of standard dispensing workstations are available for medical equipment manufacturing. The work cells can be designed with pinch tube valves that can accommodate volumes down to 0.00002 cm3 or programmable and adjustable positive-displacement valves for volumes ranging from 0.001 to 50 cm3. A z-lift can also be included to provide one axis of motion by moving the dispense valve to the part or the part to the dispense valve. Dispensing and motion are controlled by a foot switch, panel switch, or part sensors that trigger the controller. Time, cycle speed, cycle sequencing, system pressure, material feed pressure, and dispense volumes are all adjustable. Dispensit, a unit of Liquid Control, 6896 Hillsdale Ct., Indianapolis, IN 46250.

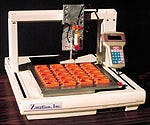

Tabletop system

A low-cost tabletop dispensing system features integrated start, stop, and e-stop buttons with a thumbwheel program selector and an integral air lockout/tagout device. The Z-300 system incorporates closed-loop servo drives for both x- and y-axis motion and a pneumatic slide for z-axis movement. With a 300 x 300-mm work area, the system can be used for a variety of fluid dispensing, filling, and assembly applications. Pressurized syringe, cartridge, or bulk material feeding can be accommodated. Zmation Inc., 14811 N.E. Airport Way, Ste. 200, Portland, OR 97230.

Cyanoacrylate systems

Operated in timed or manual mode, dispensing systems accurately dispense a variety of cyanoacrylate materials. The systems are available in handheld (System 230) and fixtured (System 240) models. Because of their replaceable diaphragms, the valves are cost- effective and can produce more

than 300,000 cycles. Kahnetics Dispensing Systems, 2260 S. Vista Ave., Bloomington, CA 92316.

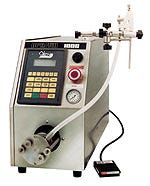

Small-volume liquid dispensing

A dispensing system features a rotary reciprocating ceramic dispense head that achieves 0.1% repeatability. The Microspense AP allows the user to calibrate the system to a specific setting and then to automatically adjust displacement to maximum for priming and maintenance modes. The unit can then return to its calibrated setting without operator involvement. The pump head design also includes improved fluidic sealing components that are appropriate for clean-in-place applications IVEK Corp., 10 Fairbanks Rd., North Springfield, VT 05150.

Filler and dispenser

A volumetric liquid filler and dispenser fills free-flowing to low-viscosity liquids in volumes ranging from 0.5 ml to 5 L. The GEN Pro/Fill 1000 system offers accurate filling, fast changeover, and clean-in-place capabilities. An optional Coriolis net mass-flow meter allows the filler to be operated in either a net weight or volumetric mode. Standard configurations include a semiautomatic benchtop system and a fully automatic high-speed filling system. Other configurations include units for form-fill-seal machines and custom-designed systems. Oden Corp., 255 Great Arrow Ave., Buffalo, NY 14207-3024.

Automatic dispenser

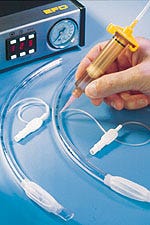

An automatic dispenser applies UV-curable adhesives in accurate, repeatable amounts. The 1500XL system combines the speed and accuracy of an air-powered fluid dispenser with barrels and tips specifically designed to apply UV-curable adhesives. Adhesive is loaded into a handheld barrel reservoir that is fitted with a precision tip and connected to the dispenser by a lightweight air line. Clear barrels and tips contain a UV-blocking additive that allows the adhesive level to be monitored without the risk of premature curing. A microprocessor-based timer permits dispense time to be adjusted in increments as little as 0.001 seconds. EFD, 977 Waterman Ave., East Providence, RI 02914-1378.

An automatic dispenser applies UV-curable adhesives in accurate, repeatable amounts. The 1500XL system combines the speed and accuracy of an air-powered fluid dispenser with barrels and tips specifically designed to apply UV-curable adhesives. Adhesive is loaded into a handheld barrel reservoir that is fitted with a precision tip and connected to the dispenser by a lightweight air line. Clear barrels and tips contain a UV-blocking additive that allows the adhesive level to be monitored without the risk of premature curing. A microprocessor-based timer permits dispense time to be adjusted in increments as little as 0.001 seconds. EFD, 977 Waterman Ave., East Providence, RI 02914-1378.

Copyright ©1999 Medical Product Manufacturing News

You May Also Like