Why Offshoring Probably Costs More than You Think

June 22, 2015

When companies weigh the decision whether to offshore manufacturing operations, they often use simple calculations that make offshoring seem less expensive than it actually is.

Brian Buntz

|

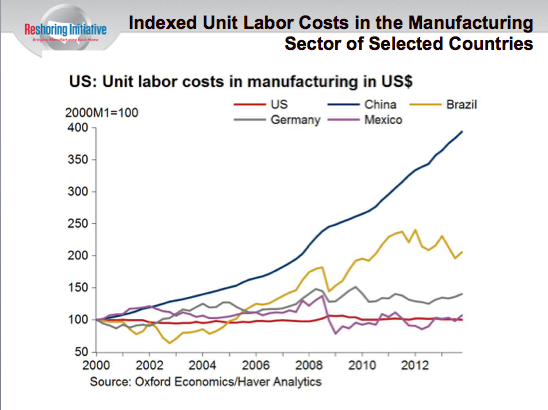

Indexed unit labor costs in China are soaring. Graph courtesy of the Reshoring Initiative. |

The arithmetic that many companies use to decide whether to move production overseas can make offshoring seem 20 to 30% less expensive than it is in reality, says Harry Moser, founder of the Reshoring Initiative (Chicago).

Moser says that some companies simply look for the cheapest hourly wage rates. A better model is to look at price, weighing the expense of making it domestically versus offshore. "Better still would be to consider landed cost, which would factor in purchase price, freight, duty and packaging." Moser says, but he points out that such a calculation would still be flawed.

To help companies paint a more accurate picture of the costs involved in manufacturing in the United States versus offshore, the Reshoring Initiative has come up with a free calculator, known as the Total Cost of Ownership Estimator, that companies can use to make better decisions.

One item included in the calculator is the carrying cost of inventory. "It turns out you typically have two or three times as much inventory of something you are importing as something you are making yourself or buying locally," Moser says.

The calculator also factors in travel costs. "If you are manufacturing in China, you might need to fly there periodically and stay for a week or two."

There are also intellectual property risks to weigh. "You have a high incidence of intellectual property theft in countries like China and some other developing countries as well," Moser says.

It's also worth thinking about the impact on innovation when you separate engineering from manufacturing. "There have been a series of studies by people like Harvard professors Gary Pisano and Willy Shih who conclude that keeping engineering and manufacturing together optimizes new product development and the process for making that product," Moser notes. "This is because the engineering people and the manufacturing people can put their heads together and optimize both of those considerations."

For some companies, moving manufacturing to the United States can actually lead to cost savings. GE was making water heaters in a contract manufacturing plant in China and importing them and selling them in the United States. "They decided they wanted to try to make them here, so they had the marketing people, the design engineers, manufacturing engineers, workers, and foremen and everybody get together. Tear the things apart and together agree on how to put them together in a better way. They innovated the design and when they were done, the thermal efficiency was improved, the warranty costs were reduced, and even though the wage rates in the United States were five times as high per hour than in the Chinese factory, the costs came down so much that the "Made in the U.S." product sells at retail for 20% than the product they had been making in China.

It's not just appliance production that is being reshored to the United States, however. The Reshoring Initiative has assembled a Powerpoint presentation cataloguing more than 300 companies that have either moved production back home or who have decided against moving manufacturing operations offshore. Included in the presentations are several suppliers to the medical device industry.

When asked why he decided to transition from being the president of AgieCharmilles LLC to the founder of the Reshoring Initiative, he recounts the story of growing up in Elizabeth, NJ, where the Singer Company had operated a gigantic plant that once employed thousands of workers "It was the biggest building in the world 100 years ago. I worked there five or six summers in my younger days. And I went back there after college and it was all gone," he says. "In the last 20 or 30 years, I have seen city after city experience the same kind of loss. So I decided to do something about it and founded the Reshoring Initiative. We would love to help companies make better decisions."

Learn more about contract manufacturing at MEDevice San Diego, September 1-2, 2015. |

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like