Why Laser Welding Matters for Neurovascular Catheters

May 13, 2016

Interventional neurology surgery is a major frontier when it comes to medical device miniaturization, and laser welding has an important role to play.

Kevin Hartke, Resonetics

|

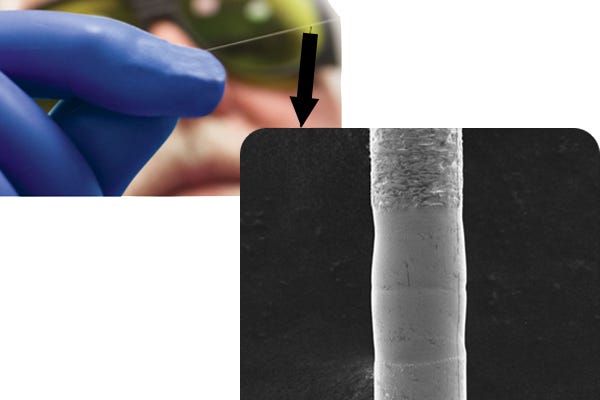

Engineer holding a 75 micron diameter nitinol wire assembly (left), high magnification view of the laser weld (right). (Images courtesy of Resonetics) |

For over 20 years, laser welding has been acknowledged as an important joining method in the medical device industry, using the native materials only without the use of any additive materials. There have been many critical applications of the technology ranging from cardiac pacemakers and implants to spinal implants, to name a few.

The rapid adoption rate is linked to the availability of laser micro-welding systems with stable output power as well as process know how. These system and process advancements have opened the door for smaller and smaller parts to be joined together in a robust process.

At the forefront of the miniaturization trend is the emergence of applications for interventional neurology surgery. Minimally-invasive delivery neurovascular catheters deliver very small implants to the brain, requiring component part sizes with outer diameters from 25 to 250 microns. Laser micro welding has proven to be a reliable and robust joining process for this critical and precise application.

Why Does Small Make Such a BIG Difference?

When the physical dimensions of life science components approach the human hair, there are many process considerations when laser welding these tiny components, including:

Geometry control: Part geometry cannot vary more than 10% of the smallest part feature, dictating single micron tolerances on all parts.

Part fixtures: Fixture design and fabrication requires specialized laser micro-manufacturing capabilities

Laser stability: Laser systems must be industrial, robust and stable, requiring the precise measurement, monitoring, and control of the laser power. Low cost jewelry welding lasers lack the power stability to guarantee a stable process.

Part handling: Part manipulation requires skilled technicians who use micro-manipulators with the aid of optical microscopes.

Laser Welding: Art vs. Science

Welding has evolved. For the interventional neurology industry, the image of a traditional welder donning a protective mask shield to protect against flying orange and white sparks is an antiquated notion; instead micron-scale laser welding is the new norm.

Picture an operator inside a clean room, using an optical microscope to load parts into a precision fixture, which is in turn loaded into a completely automated machine. Laser welding for the neurointerventional industry uses validated machines and processes that are capable of producing thousands of parts per week with process capability values well above a Cpk of 1.33.

From the beginning, laser welding processes are designed with manufacturability and repeatability in mind, accelerating the product time-to-market by allowing contract manufacturers to deliver quick-turn prototypes, followed by scalable volume manufacturing. Moving seamlessly from development to production requires expert laser knowledge of the process parameters, material weldability, geometry control, fixture design/manufacturing, and part handling. Collectively these factors are critical for a successful implementation of micron-level laser welding for high valued applications such as neurovascular and neuromodulation.

Learn more about cutting-edge medical devices at MD&M East, June 14-15, 2016 in New York City. |

Kevin Hartke is chief technology officer at Resonetics (Nashua, NH).

About the Author(s)

You May Also Like