Converting 2-D Textiles into 3-D Medical Devices

December 1, 2014

BIOMEDevice San Jose exhibitor J-Pac Medical (Somersworth, NH) has a knack for thinking outside of the box. For instance, the company managed to take blister packaging and convert it into a diagnostic product that is receiving international attention from diagnostic companies.

The product is but one example of the evolution the firm has undergone in the past three decades--an evolution many medical device contract manufacturers have been going through. The company's roots lie in doing thermoformed packaging for medical devices. Over the years, the firm has steadily expanded the scope of its services, which now includes a range of contract manufacturing services.

|

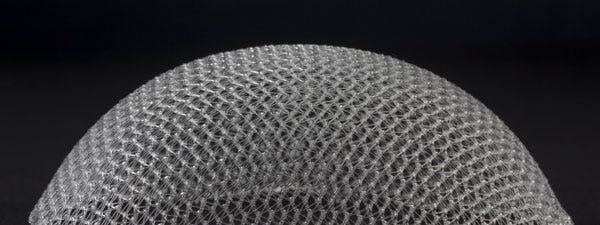

A 3-D spherical shaped knitted mesh fabricated into an anatomically relevant shape from a piece of flat textile fabric. |

"From our perspective, what we do fundamentally revolves around manipulating the thermal properties of polymers," says Jeff Koslosky, vice president, marketing and business development. "They just happen to be medical implantable polymers that we are playing with. We have a variety of forming and cutting and shaping techniques that we have evolved." The company uses everything from ultrasonic sewing and welding to ultrasonic and radiofrequency sealing and cutting.

The aforementioned diagnostic technology rooted in packaging technology is unique in that it was something of a happy accident rather than something the company deliberately sought to create. "It was an example of something that made us think, 'Oh, that is different from what we expected.' We later realized, 'Wait a minute, that is pretty cool,'" Koslosky says. "It is nice when that happens but it is better to say, 'I mean to do that.'"

An example of more deliberate innovation from the company is its work with textiles. The company is leveraging its background with packaging to convert textiles from a flat material to a three-dimensional one that can conform anatomical region in the body. "For instance, it can be designed to go into a particular space and transformed to a three-dimensional shape after a surgeon pulls on a suture or something along those lines," Koslosky says. "Our expertise is taking that fabric and converting it into a device."

J-Pac Medical's growing palette of service offerings has helped it to coax 2-D textiles into 3-D shapes. For instance, the company has a proprietary vacuum molding process that it uses for the purpose. "The science is in how you heat it, what is the dwell time you heat it for, what method you use," Koslosky says. "Do you use ultrasonic or radiofrequency, or a combination of all of those to get a three dimensional geometry?"

At the end of the day, the company works closely with medical device clients to give them a particular shape that is not possible with textile forming equipment. Applications could be everything from hernia repair to cardiovascular plugs, and endovascular aneurysm devices. "We are looking into heart valves and orthopedics as well," Koslosky notes. "We can use it anywhere there is an opportunity to leverage a two-dimensional material and coax it into a three dimensional shape."

Check out J-Pac Medical (Booth #1320) at BIOMEDevice San Jose, December 3-4, 2014. |

Brian Buntz is the editor-in-chief of MPMN and Qmed. Follow him on Twitter at @brian_buntz.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)