A Google Docs-Like Approach to Keeping Your Suppliers in Line

March 11, 2015

MasterControl offers a software system to help OEMs virtually collaborate with their contract partners.

Brian Buntz

When Google Docs hit the scene back in 2007, my first reaction was to wonder about the purpose of a simple browser-based clone of Microsoft Word. Now, I use the platform almost daily-- and even wrote this text using the platform. It makes sharing and editing documents remotely a snap, making it easy to have others edit or proofread your documents--all without sending a string of Word documents back and forth between a collaborator via email. And Google's search capability makes retrieval of archived documents seem nearly instantaneous.

MasterControl (Salt Lake City, UT) has come up with a similar approach to help medical device companies partner with contract manufacturers. Known as Guest Connect, the system could be especially helpful for life science firms that use contract manufacturing extensively, such as many orthopedic device companies.

|

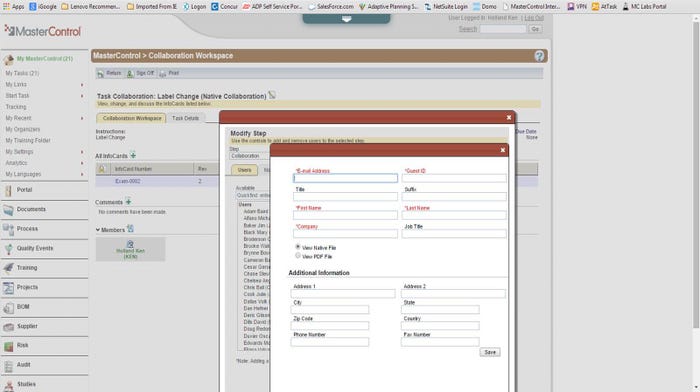

MasterControl software enables remote collaboration with contract manufacturers. |

As any contract manufacturer will tell you, involving them up front can help avoid production problems and can ultimately improve the quality of your product in the long run. But that rarely seems to happen.

The Guest Connect system was designed to facilitate such interactions by involving contract manufacturers electronically, helping them collaborate on specifications for products in development. "You can grant them access to an online collaborative workspace where you take a look at those specifications, mark them up, make comments on them, and go back and forth, to the point that all parties mutually agree that the thing can be produced within the tolerances specified without a high degree of quality defects," says Matt Lowe, executive vice president, global sales and marketing at MasterControl. "When you can do that part up front, then you don't have to worry down the road when they start delivering product to you that you have problems in an incoming inspection.

The system can help foster collaboration and supplier management in the long term, Lowe says. And in addition to collaborating on specs, the system can enable a contract manufacturer to submit deviation requests electronically through the system. Or an OEM can issue supplier corrective actions through the system and manage audits through the system. "You can also create a scorecard of your vendors to monitor their performance for quality and financial perspectives by integrating that with your enterprise resource planning (ERP) system.

Refresh your medical device industry knowledge at BIOMEDevice Boston, May 6-7, 2015. |

Brian Buntz is the editor-in-chief of MPMN and Qmed. Follow him on Twitter at @brian_buntz.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)