5 Interesting Exhibitors at BIOMEDevice San Jose

November 24, 2014

A walk around the expo floor at a UBM Canon medical device industry show can often provide a window into all of the different type of things--from materials to molding to contract manufacturing services--that go into producing finished medical devices.

Such innovations are important because they enable overall medtech advances that not only amaze but also save lives.

|

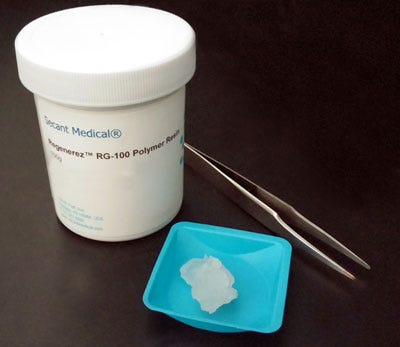

Regenerez is a bioresorbable elastomer made from poly(glycerol sebacate). |

Here are five exhibitors you should try to check out at the upcoming BIOMEDevice San Jose, which runs from December 3 -4 at the San Jose Convention Center.

1. Advanced Biomaterials Engineering

Secant Medical: Booth 640

The development of vascular access and delivery devices demands careful consideration of the best combination of material and dimensions while accounting for the harsh conditions of the human anatomy. Enter Secant Medical (Perkasie, PA) with its PGS biomaterial called Regenerez that is stretching the old biomaterial paradigms, providing an alternative to the poly lactic acid, poly glycolic acid, poly caprolactone, and poly dioxanone that had previously dominated that biomaterials space for decades. Regenerez has potential for tissue engineering in a variety of in vivo applications for cardiovascular, neurovascular, orthopedics and general surgery.

2. Stent Measuring Machine

Werth Inc.: Booth 1042

The StentCheck multisensor coordinate measuring machine (CMM) from Werth Inc. (Old Saybrook, CT) is meant to provide reliable measurement accuracy for stents. It heavn has special software algorithms to prevent false measurements such as those caused when struts are severely bent.

|

Proto Labs' business is geared around customized, fast manufacturing. |

3. Fast LSR Injection Molding

Proto Labs: Booth 406

Proto Labs (Maple Plain, MN) boasts proprietary software and automated manufacturing processes that allow for quick-turn prototyping and low- to mid-volume production of real plastic and metal parts within days. Through its Protomold injection molding service, it offers liquid-silicone-rubber (LSR) molding as an addition to its established portfolio of metal and plastic material capabilities. A thermoset engineering material suited for medical device applications, LSR can withstand sterilization and is biocompatible.

4. Engineered Surface Tubing

Zeus Inc.: Booth 621

Zeus (Orangeburg, SC) will be showing off engineered-surface tubing that increases lubricity while decreasing drag force without using fillers or additives. Such surfaces can increase safety for patients undergoing minimally invasive medical procedures such as needle biopsy and laparoscopy. Zeus offers an engineered surface on a range of polymers including PEEK, FEP, PFA, PVDF, ETFE, and nylon.

|

Surgical Technologies provides a great example of a contract manufacturer offering comprehensive services. |

5. Contract Manufacturing

Surgical Technologies: Booth 930

Take a look at the typical contract manufacturing firm now versus 10 years ago, and it is likely bigger and with many more capabilities. Surgical Technologies (St. Paul, MN) is a great example of this trend. It offers comprehensive services that, from initial customer contact through final processing of products, are performed in accordance with rigid internal standards and the current expectations of the medical technology market. The company provides in-house assembly, packaging, and sterilization of products.

Refresh your medical device industry knowledge at BIOMEDevice San Jose, December 3-4, 2014. |

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)