Three Critical Factors for Force and Pressure Sensors in Infusion Pumps

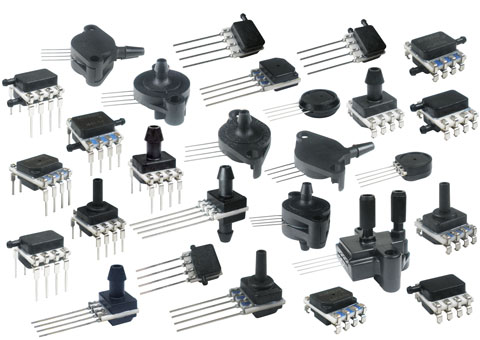

A modular design enables infusion pump manufacturers to use a single sensor model in a variety of applications.

May 16, 2013

Reliability, sensitivity, and miniaturization are three critical factors to consider when choosing force and pressure sensors for infusion pumps, which deliver medication to patients intravenously. As infusion pumps transition from bulky models to portable, ambulatory, and implantable devices, designers should consider sensor platforms that provide a range of options that make them easy to implement in a variety of designs.

The modular design of Honeywell Sensing and Control's TruStability® board-mount pressure sensors, enables infusion pump manufacturers to use a single sensor model in a variety of applications. The sensor platform's custom calibration, together with multiple output, power, pressure, mounting and packaging options increase design flexibility. |

Designers should also consider pressure sensors that are fully compensated, amplified, and calibrated. The benefits include lower total costs, higher reliability, and faster speed to market.

Force and pressure sensors must provide high reliability and high sensitivity to ensure the desired amount of medication is being delivered to the patient. Board-mount pressure sensors are used inside the pump to monitor and help control the flow of fluid. Force sensors on the outside of the pump measure force in the tubing that delivers the medication. Force sensors can detect if there are any blockages in the pump's tubing and signal an audible alarm if the medication is not being delivered. A modular design enables infusion pump manufacturers to use a single sensor model in a variety of applications.

Force sensors also benefit from a platform approach. Force sensors that use the same sense element—the smallest building block in a sensor design—as pressure sensors enable manufacturers to validate the sense element for both, thus making it possible to quickly scale the force sensors across ranges and respond to demand spikes and requests for samples.

Force sensors offer many options including different packages to accommodate the different ways the sensors are attached to the infusion pump's tubing. These sensors use piezoresistive technology that provides precise and reliable force sensing in a small package. The high sensitivity to minute force changes enables early detection of occlusion, which improves patient safety.

For force sensors, used particularly in infusion-pump and dialysis applications, the option requiring the greatest flexibility is the availability of different packaging styles. As an example, the addition of gull-wing leads to force sensors allows the medical device manufacturer to move from a through-hole to a surface-mount design, which meets today's high-volume manufacturing needs. A surface-mount design eliminates the need for hand-soldering, allowing for a more streamlined production process.

By providing smaller size options, the component can be integrated into space-constrained infusion pump designs. Their small size and low-power consumption can improve a patient's quality of life by increasing the portability of the infusion or insulin pump.

AJ Smith is director of product marketing at Honeywell Sensing and Control, where he is responsible for leading, managing, and directing all product-marketing-related activities within the pressure and thermal business. He holds a bachelor's degree in chemistry from the University of Illinois at Urbana-Champaign and received his MBA from the University of Minnesota Twin Cities campus with specializations in finance, strategic management, and international business. He can be reached at [email protected].

Related Content

Platform Sensors Enable Design for Flexibility

How Platform Sensors Can Help Developers of Ventilators and Anesthesia Systems

Dialysis: A Marriage of Thermal Management and Pressure Sensing

How Sensors Assist Surgeons in Eye Surgery

Wound Therapy: Using Pressure Sensors to Measure Vacuum

Platform Sensors Fulfill High Sensitivity and Repeatability Requirements for Analytical Instruments

You May Also Like