This Transparent, Bendable Conductor Could Improve Flex Electronics

June 24, 2015

Using a "nano-accordion" design, researchers have developed a new stretchable, transparent conductor that could prove crucial in the wave of next-gen flexible electronics and wearable technologies.

Kristopher Sturgis

|

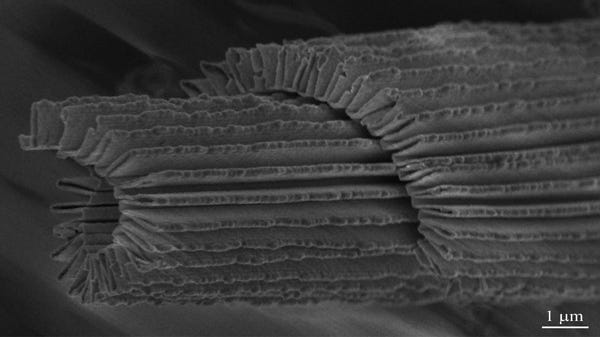

North Carolina State University researchers created a series of symmetrical, zinc oxide ridges on an elastic substrate. These ridges of zinc oxide allow the structure to expand and contract like a nano-accordion, giving it its flexible, bendable traits. (Image courtesy of NCSU.) |

Researchers from North Carolina State University in Raleigh have developed a new kind of conductor with impressive stretchy and transparent qualities that could potentially enhance the next generation of flexible electronics and wearable technologies, according to a university news release.

The search for pliable, stretchable conductors that are as efficient as they are flexible have been an area of focus for many engineers and researchers who look to take flexible electronics and wearable technologies to the next level. It wasn't long ago, in fact, that NC State University researchers produced one of the first elastic conductors from silver nanowires.

Abhijeet Bagal, PhD student in mechanical and aerospace engineering at NC State and lead author on the paper describing the work, noted that the group set out to create a conductor made from transparent, stretchable materials while maintaining highly conductive properties. They wanted something that could really push flexible electronics and wearable technologies into the next-gen phase.

"Conventional electronics are not suitable for applications involving complex curvilinear surfaces, such as human skin, tissues, and complex robotics," Bagal said. "Flexible conductors can readily conform to such surfaces and work efficiently. Additionally, the conductor we made is transparent, which will make it suitable for applications involving flexible displays, and transparent wearable sensors to achieve augmented reality."

The team began by creating a three-dimensional polymer template on a silicon substrate. The template, which is shaped like a series of identical evenly spaced rectangles, is then coated with a layer of aluminum-doped zinc oxide, which acts as the conducting material. Finally, an elastic polymer is applied to the zinc oxide, before the whole thing can be flipped over to remove the silicon and the template.

What remains is a series of symmetrical, zinc oxide ridges on an elastic substrate. These ridges of zinc oxide allow the structure to expand and contract like a nano-accordion, giving it its flexible, bendable traits. And because both the zinc oxide and polymer are clear, the remaining structure becomes transparent.

"I think the fact that these are transparent really opens up some interesting prospects," said Erinn Dandley, PhD student in chemical and biomolecular engineering at NC state, and co-author on the paper. "Being flexible and transparent seems like it could be incorporated into a contact lens for some type of bio-electronic interface. It's also unique that we can change the thickness of the film, which allows us to have a lot more leeway to tailor the nano-accordions to specific and diverse applications."

Dandley noted that the group have done extensive testing with the thickness of the zinc oxide layers, ranging from 30 to 70 nanometers thick, which is important given that the thickness of the zinc oxide layer affects the structure's optical, electrical, and mechanical properties.

The group tailored the 3-D templates in the process using nanolithography, as the dimensions of each ridge directly affected the structure's stretchability. The taller each ridge is, the more stretchable it becomes. They found that the structure can be stretched repeatedly without breaking, and while there is some loss of conductivity the first time it is stretched, additional stretching does not further affect conductivity.

"In addition to being a stretchable transparent conductor, the most unique thing about this work is that we can precisely control the geometry of the nano-accordion structure through nanolithography and material composition through ALD process," Bagal said. "This helps us design the conductors with controllable mechanical, electrical, and optical properties."

For now, the team is also experimenting with other conductive materials using this technique to determine their usefulness in creating elastic conductors that are non-transparent. While using metals would be more conductive and more bendable, they do lack the optical properties of their current nano-accordion structure. They're also hoping that new geometries might help them achieve bi-directionally stretchable conductors.

Refresh your medical device industry knowledge at MEDevice San Diego, September 1-2, 2015. |

Kristopher Sturgis is a contributor to Qmed and MPMN.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)