Soon You Can Have Your Battery and Wear It Too

May 16, 2014

Chalk up another "Amazing!" for the miracle materials graphene and carbon nanotubes.

|

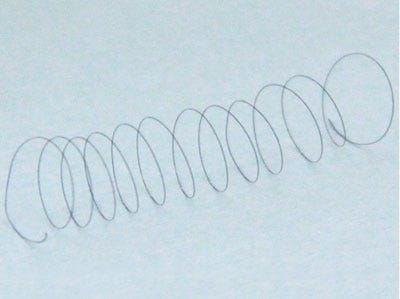

Graphene and carbon nanotube hybrid fiber (Courtesy Nanyang Technological University) |

A team of researchers from Nanyang Technological University (Singapore), Tsinghua University (Beijing), and Case Western Reserve University (CWRU; Cleveland, OH) has developed a fiber-like supercapacitor made from graphene and carbon nanotubes that is flexible enough to be woven into clothing and has the highest energy density attained to date for a carbon-based supercapacitor.

Liming Dai, PhD, professor of macromolecular science and engineering at Case Western Reserve and a co-author of the paper, explained in a CWRU press release that most supercapacitors have high power density but low energy density, which means they can charge quickly and give a boost of power, but don't last long.

Conversely, batteries have high energy density and low power density, which means they can last a long time, but don't deliver a large amount of energy quickly. Therefore the challenge for researchers is to develop power sources that have both high energy density and high power density.

Using a polyvinyl alcohol/phosphoric acid gel as an electrolyte, a supercapacitor made from a pair of the fibers offered a volumetric density of 6.3 microwatt hours per cubic millimeter, a new record, which is comparable to that of a 4-volt-500-microampere-hour thin film lithium battery.

In a paper published in Nature Nanotechnology, "Scalable Synthesis of Hierarchically Structured Carbon Nanotube-Graphene Fibres for Capacitive Energy Storage," the team describes their discovery as "a hierarchically structured carbon microfibre made of an interconnected network of aligned single-walled carbon nanotubes with interposed nitrogen-doped reduced graphene oxide sheets."

A solution containing acid-oxidized carbon nanotubes, graphene oxide and ethylene diamine, which dopes the graphene with nitrogen, is pumped through a capillary column and heated in an oven for six hours. The graphene and carbon nanotubes self-assemble into an interconnected porous network that run the length of the fiber. This scalable process has already been used to make fibers as long as 50 meters.

The supercapacitors have a lifespan about 10 times that of conventional rechargeable batteries. "We have tested the fiber device for 10,000 charge/discharge cycles, and the device retains about 93 percent of its original performance," lead author Dingshan Yu said, "while conventional rechargeable batteries have a lifetime of less than 1000 cycles."

The team also tested the flexibility of the fibers. "The fiber supercapacitor continues to work without performance loss, even after bending hundreds of times," Yu said. Because they remain flexible, the fibers might be woven into clothing.

"The team is also interested in testing these fibers for multifunctional applications, including batteries, solar cells, biofuel cells, and sensors for flexible and wearable optoelectronic systems," Dai said. "Thus, we have opened up many possibilities and still have a lot to do."

Stephen Levy is a contributor to Qmed and MPMN.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)