Scientists Invent Flexible, Stretchable Circuits with 3-D Printer

June 23, 2014

|

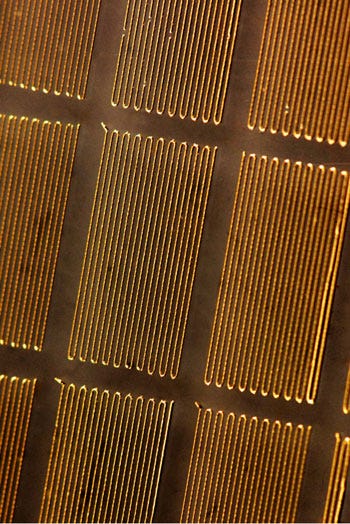

A liquid-alloy pattern 3-D printed in a rubber-like polymer forms a network of sensors. (Courtesy Rebecca Kramer/Purdue University) |

Researchers at the Purdue University School of Mechanical Engineering (West Lafayette, IN) have developed a technique to embed a liquid-alloy pattern inside a rubber-like polymer to form a network of flexible sensors.

These flexible circuits might be used to produce 'soft machines' made of elastic materials and liquid metals for potential applications in robotics, medical devices and consumer electronics. A paper published in Advanced Functional Materials, "Direct Writing of Gallium-Indium Alloy for Stretchable Electronics," describes the scientists' developments.

The authors say that such an elastic technology could one day make possible robots that have sensory skin, and stretchable garments that people might wear to interact with computers or for therapeutic purposes.

Rebecca Kramer, an assistant professor of mechanical engineering at Purdue University, and her team have thus far employed their technique to to create a flexible version of a device called a strain gauge. Strain gauges are commonly found in many commercial applications to measure how much something is being stretched. Because conventional strain gauges are made of a rigid metal film, they can't measure more than a 1-percent deformation before breaking.

The team's soft strain gauge could continue stretching with the material, measuring 100 percent of a material's strain. "What's exciting about the soft strain gauge is that it can detect very high strains and can deform with almost any material," Kramer says. "The skin around your joints undergoes about 50 percent strain when you bend a limb, so if you wanted to have sensory skin and wearable technology that tracks your movement, you need to employ soft, stretchable materials that won't restrict your natural range of motion."

Findings in the research paper describe how to use the 3D printer to create soft strain gauges. "If you want to achieve a strain gauge device and you want the traces to be a certain width or height, we can tell you with our paper exactly what parameters you should choose... . We have created a design strategy for 3D printing liquid metals," Kramer says.

Kramer and her team, which includes lead author J. William Boley, a postdoctoral research associate; doctoral student Edward L. White; and George T.C. Chiu, a professor of mechanical engineering, used a custom-built 3-D printer to embed patterns of lines of liquid gallium-indium alloy in a rubber-like polymer called polydimethylsiloxane (PDMS).

Refresh your medical device industry knowledge at MEDevice San Diego, September 10-11, 2014. |

"It has some odd properties," Kramer explains. "Gallium oxidizes really quickly and forms a thick gallium-oxide skin, which is challenging to work with using typical liquid-processing techniques."

However, the Purdue researchers have invented a method that takes advantage of the alloy's oxidized skin. "We exploit this oxide skin by using it for structural stability. This means you can print liquid on a surface and it will maintain stable structures without moving around," Kramer elaborates. "We use this finding to embed our electronics in elastomer without ruining or altering the printed structures during the processing steps."

"Our process enables digital fabrication of the sensors on the micro-scale," Kramer says. "While this is a huge step forward, we need to continue to decrease scale and increase density to develop sensors and electronics that are comparable to traditional, rigid devices and that mimic the functionality of human skin."

Stephen Levy is a contributor to Qmed and MPMN.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)