Relying on Body Motions, Rubber Films Could Eventually Power Pacemakers and other Medical Devices

January 28, 2010

rubber-nanoribbons1 |

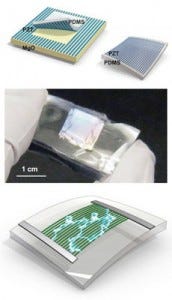

Process for deriving electricity from rubber films: The top image shows how piezoelectric nanoribbons are peeled off a host substrate and placed onto rubber. The middle image shows the piezorubber chip. The bottom image illustrates the energy harvesting circuit, which generates power when it is bent. (Credit: Michael McAlpine/Princeton University) |

Engineers from Princeton University (Princeton, NJ) have developed power-generating rubber films that rely on natural body movements such as breathing and walking. The technology could eventually power electronic devices, including those used in medical applications.

Composed of ceramic nanoribbons embedded onto silicone rubber sheets, the material generates electricity when it is flexed and is highly efficient at converting mechanical energy to electrical energy. Shoes made from this rubber may one day harvest the pounding of walking and running to power mobile electrical devices. Placed against the lungs, sheets of the material could use breathing motions to power pacemakers, eliminating the need to replace batteries surgically.

Presented in "Piezoelectric Ribbons Printed onto Rubber for Flexible Energy Conversion," a paper published in Nano Letters, the Princeton team's work is the first to successfully combine silicone and nanoribbons of lead zirconate titanate (PZT), a piezoelectric ceramic material that generates an electrical voltage when pressure is applied to it. Able to convert 80% of the mechanical energy applied to it into electrical energy, PZT is the most efficient of all piezoelectric materials.

"PZT is 100 times more efficient than quartz, another piezoelectric material," remarks project leader Michael McAlpine, a professor of mechanical and aerospace engineering at Princeton. "You don't generate that much power from walking or breathing, so you want to harness it as efficiently as possible."

silicone-rubber-electricity1 |

A piece of silicone rubber imprinted with super-thin material can generate electricity when flexed. (Credit: Frank Wojciechowski) |

The researchers first fabricated PZT nanoribbons--strips so narrow that 100 of them side by side are 1 mm wide. In a separate process, they embedded these ribbons into clear sheets of silicone rubber, creating what they call "piezorubber chips." Because the silicone is biocompatible, it is already used for cosmetic implants and medical devices. "The new electricity-harvesting devices could be implanted in the body to perpetually power medical devices, and the body wouldn't reject them," McAlpine explains.

In addition to generating electricity when it is flexed, the material also flexes when an electrical current is applied to it. This opens the door to other kinds of applications, such as microsurgical devices, McAlpine notes.

"The beauty of this is that it's scalable," comments Yi Qi, a postdoctoral researcher working with McAlpine. "As we get better at making these chips, we'll be able to make larger and larger sheets of them that will harvest more energy."

The research was funded by the United States Intelligence Community, a cooperative of federal intelligence and national security agencies.

You May Also Like