Maximizing Signals in Active Catheters

Junkosha shared its new solutions for increasing signal capacity in electrophysiology catheters during MD&M West 2021.

September 7, 2021

Medtech is trending toward developing “active catheters,” such as those offering an electrical or sensing function for “less-invasive diagnostic imaging,” Kevin LaDow, Junkosha’s medical products manager for USA West, shared with MD+DI during MD&M West. But sending electrical signals through very narrow catheters can be challenging, he acknowledged.

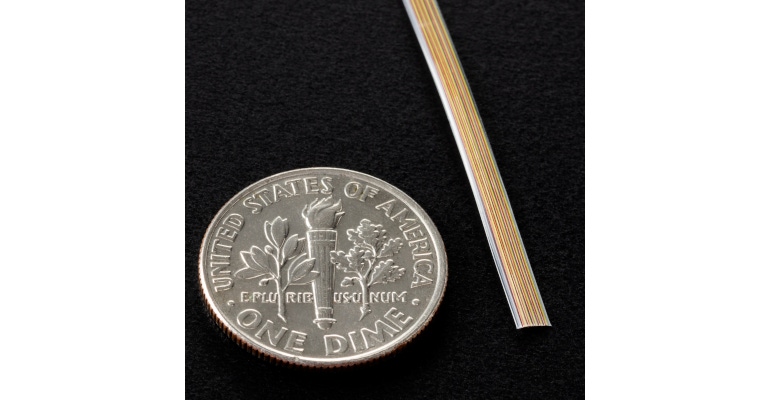

At MD&M Junkosha shared its Multi-Filar cables as a potential solution for active catheters. “To optimize imaging performance in a more complete assembly package, we offer an array of signal lines and ground lines in a single multi-filar cable assembly,” he explained. “Our new solutions can maximize the number of signals while minimizing the overall profile.”

According to the company, its Multi-Filar cables have a capacity of up to 60 total lines—depending on AWG size, cable type, or pitch—and they are designed to provide not only increased functionality but also more signals into formerly inaccessible areas of the body.

The Multi-Filar cables employ precision-engineered PTFE lamination technology that joins single strands into a single multi-filar assembly. Positioning between the individual strands can be adjusted to maximize strength for challenging assembly conditions or to optimize for difficult separation and subassembly processes. Even dissimilar single-strand alloys can be joined together in one package. The technology could be used in electrophysiology catheters for applying pacing and recording protocols from inside the heart, ablation and balloon ablation catheters for atrial fibrillation, and for cardiac-mapping catheters, the company shared.

Junkosha also offers its patented Multi-Channel Transmission (MCT) cables designed to provide individually insulated microwires with optimized shielding/grounding to increase signal capacity for a given size while also optimizing for key characteristics like signal transmission quality and signal loss or noise, the company reported. MCT enables multiples of four signals to be brought together in one transmission line, therefore significantly increasing the respective signal capacity per unit diameter, it added. Potential applications include therapies such as intracardiac echocardiogram, ultrasound endoscopy, and intervascular ultrasound (IVUS). Early prototypes have achieved a 32% reduction ratio in the size of the cable when compared to a standard coax of an identical AWG size, a critical factor in the attainment of future procedures within narrower vessels as well as accommodating more demanding catheter designs, Junkosha reported.

At MD&M West Junkosha also launched its challenge to explore whether tie layers are really needed for its PTFE liners in the manufacture of catheters. As an alternative to tie layers, the company offers an etched PTFE liner that provides consistent tensile strength and elongation properties with an enhanced etched surface to allow for stronger bonds to jacket material, LaDow explained. “When it comes to PTFE, people are really struggling with consistency and bondability,” he said. “Nothing sticks easily to PTFE, so you have to etch it. Some are coating with a tie layer, but we don’t think they need to. If you add an extra layer, it makes the device bigger, and mechanically, since you usually have to stretch the liner to neck down onto a mandrel, liners with tie layers face limitations with regard to stretching. To me, the fewer layers, the better.” To read more about the challenge, click here.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)